Slender bar plating hanger

A technology for electroplating hangers and bars, applied in the direction of electrolysis process, electrolysis components, etc., can solve problems such as consumption, large manpower and material resources, and bar damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

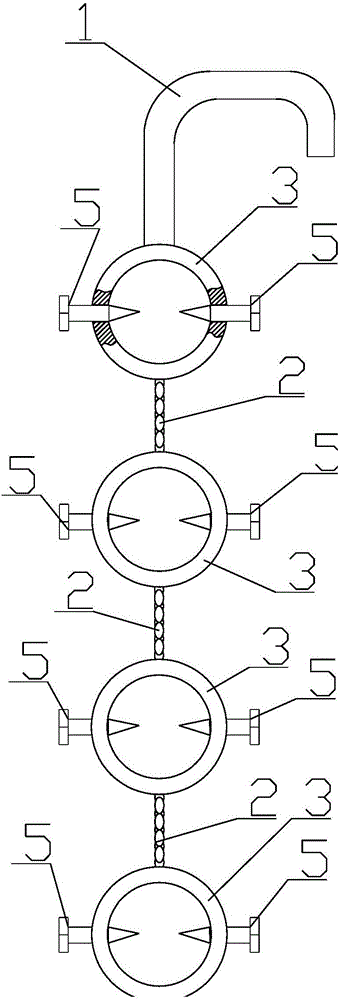

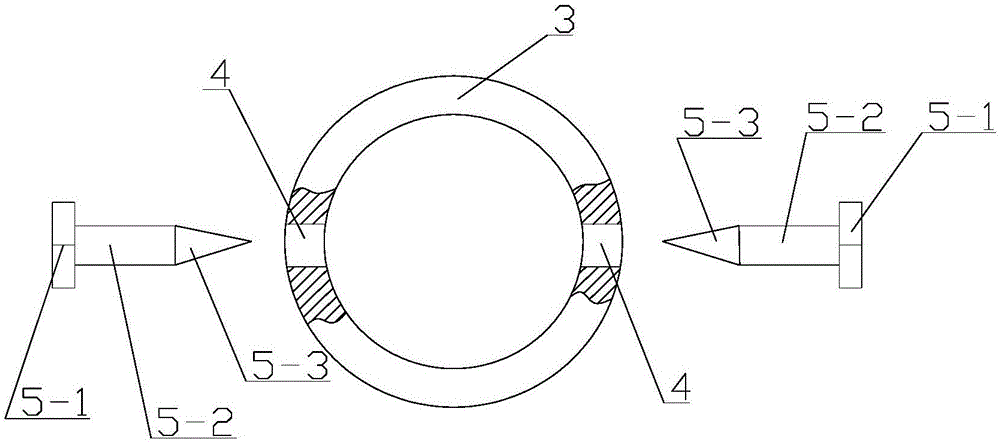

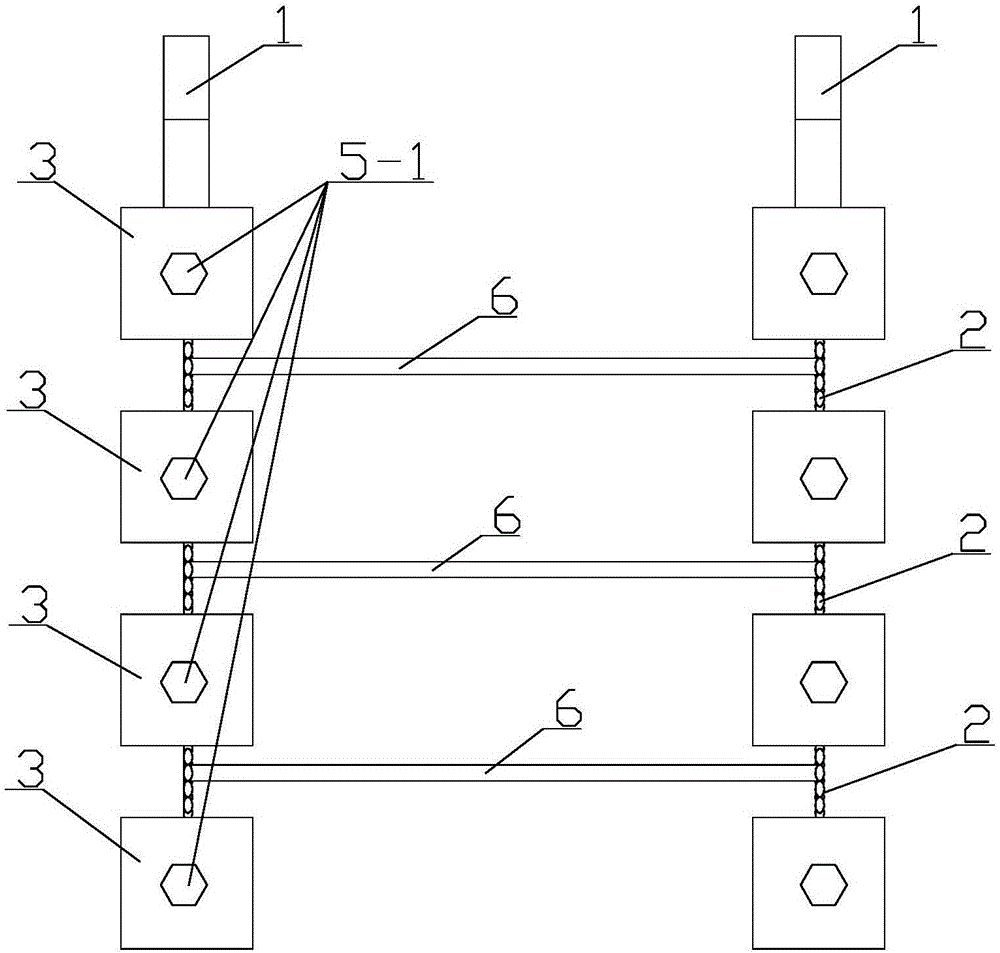

[0017] like Figure 1~4 Shown is the electroplating hanger for slender rods, including the hanger body, the hanger body includes a hook 1, a plurality of tubular clamp assemblies and a chain 2, and the lower end of the hook 1 is fixedly connected to a plurality of tubular clamp assemblies. A chain 2 is fixedly connected between each tubular clamp assembly; multiple tubular clamp assemblies include an outer tube 3, a fixing hole 4 and a fixing screw 5, and the outer tube 3 is symmetrically provided with fixing holes 4 in the radial direction, and the fixing screw 5 is movable Set in the fixing hole 4.

[0018] Wherein, the hanger body is set in two or more groups. Two or more sets of chains 2 in the hanger body are connected with crossbars 6 , and the two ends of crossbars 6 are inserted in the chains 2 . The fixing screw 5 in the plurality of tubular clamp assemblies includes a screw head 5-1, a screw handle 5-2 and a fixed end 5-3, and the screw head 5-1, the screw handle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com