Method for preparing chitin oligosaccharides, chitooligosaccharides and chitosan oligosaccharides

A technology of chitooligosaccharide and chitin, which is applied in the preparation of chitooligosaccharide and chitin oligosaccharide, and the field of chitin oligosaccharide, can solve the problem of inability to control the molecular weight of degradation products, and achieves easy control of the reaction process, The effect of high yield and easily controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a specific embodiment, the preparation method of chitin oligosaccharides, chitooligosaccharides and chitooligosaccharides of the present invention may further comprise the steps:

[0031] (1) Use a pulverizer to pulverize the flake chitin to an appropriate particle size, generally about (80-200 mesh).

[0032] (2) Chitin particles are dispersed in 5 times to 50 times of solvent, and under strong stirring, chitin fully swells or dissolves in the solvent.

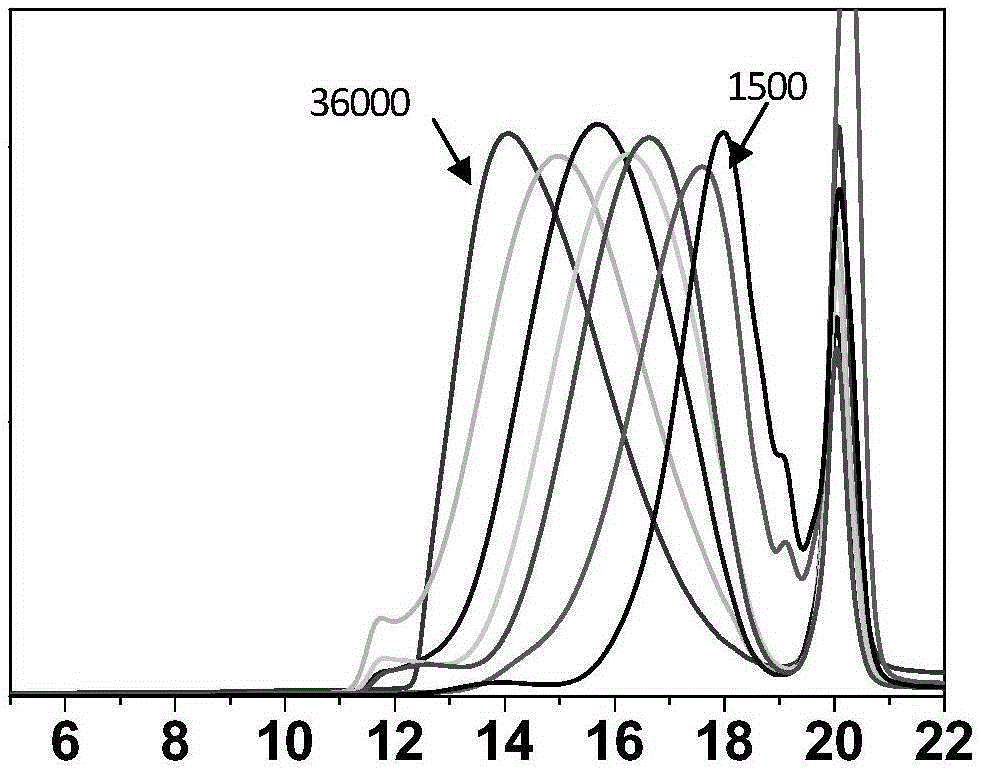

[0033](3) The reactant is kept at 0° C. to 100° C. for 1 to 10 hours, the chitin begins to degrade, and the molecular weight gradually decreases to obtain chitin oligosaccharides. Chitin oligosaccharides with different molecular weights can be obtained by controlling the reaction time.

[0034] (4) Remove the reaction liquid solvent and purify the chitin oligosaccharide obtained by the reaction by evaporating the solvent under reduced pressure in a vacuum, alcohol precipitation, column chromatography, membrane separ...

Embodiment 1

[0039] At 10°C, 10 g of chitin was slowly added into 200 mL of concentrated hydrochloric acid (36 wt%). After stirring for 6 hours, the chitin was completely dissolved. Raise the reaction temperature to 30° C., stir for 1 hour, and then slowly add NaOH solid powder to the reaction solution to neutralize the reaction solution. 1000 mL of ethanol was added to the reaction solution for alcohol precipitation, and the precipitated solid precipitate was filtered, washed with ethanol, and air-dried to obtain 8 g of chitin oligosaccharides.

[0040] 8 grams of chitooligosaccharides were added to 160 grams of 50 wt% NaOH solution. The reaction temperature was kept at 90°C for 6 hours. After the reaction was finished, 800 mL of ethanol was added for alcohol precipitation. The precipitated solid precipitate was filtered, washed with ethanol, and freeze-dried to obtain 6 g of white chitooligosaccharide powder. The molecular weight of chitooligosaccharide is 11000, and the degree of de...

Embodiment 2

[0042] At 10°C, 10 g of chitin was slowly added into 200 mL of concentrated hydrochloric acid (36 wt%). After stirring for 6 hours, the chitin was completely dissolved. Raise the reaction temperature to 30° C., stir for 1.5 hours, and then slowly add NaOH solid powder to the reaction solution to neutralize the reaction solution. 1000 mL of ethanol was added to the reaction solution for alcohol precipitation, and the precipitated solid precipitate was filtered, washed with ethanol, and air-dried to obtain 7.5 g of chitin oligosaccharides.

[0043] 7.5 grams of chitin oligosaccharides were added to 160 grams of 50 wt% NaOH solution. The reaction temperature was kept at 90°C for 6 hours. After the reaction was finished, 800 mL of ethanol was added for alcohol precipitation. The precipitated solid precipitate was filtered, washed with ethanol, and freeze-dried to obtain 5.8 g of white chitooligosaccharide powder. The molecular weight of chitooligosaccharide is 5000, and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com