Novel electric ignition fusehead and preparation method thereof

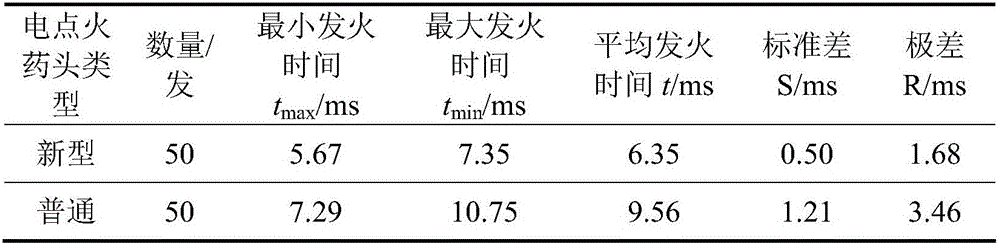

A technology for igniting powder and powder, which is applied in the direction of explosives, etc., can solve the problems of low ignition time accuracy, pollute the environment, and endanger human health, etc., and achieve the effect of improving intrinsic safety, ideal use effect, and high ignition time accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention: the novel ignition charge, calculated in parts by mass, includes 40-98 parts of nickel hydrazine nitrate, 1-30 parts of lead dioxide, 1-30 parts of zirconium powder and 100-150 parts of binder. Prepare ingredients.

[0014] The adhesive is a nitrocellulose butyl acetate solution with a mass percentage of 1-10%, or a polyvinyl alcohol aqueous solution with a mass percentage of 3-16%.

[0015] The preparation method of novel ignition charge, each component is taken by above-mentioned mass parts, comprises the following steps:

[0016] 1) Put the adhesive into a mixing container, add lead dioxide and zirconium powder to the adhesive to obtain product A;

[0017] 2) Add nickel hydrazine nitrate to product A again to obtain product B;

[0018] 3) Place the mixing container under the mixing machine, and the stirring paddle goes deep into the liquid surface of the container. After the person leaves the mixing room, start the mixer, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com