Special hoisting sling and hoisting method for nuclear power station CR10 and reinforcing steel bar composite module

A CR10, nuclear power plant technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problem of unable to meet the hoisting needs of nuclear power plant CR10 and steel bar combination modules, and achieve the effect of scientific hoisting method, easy construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

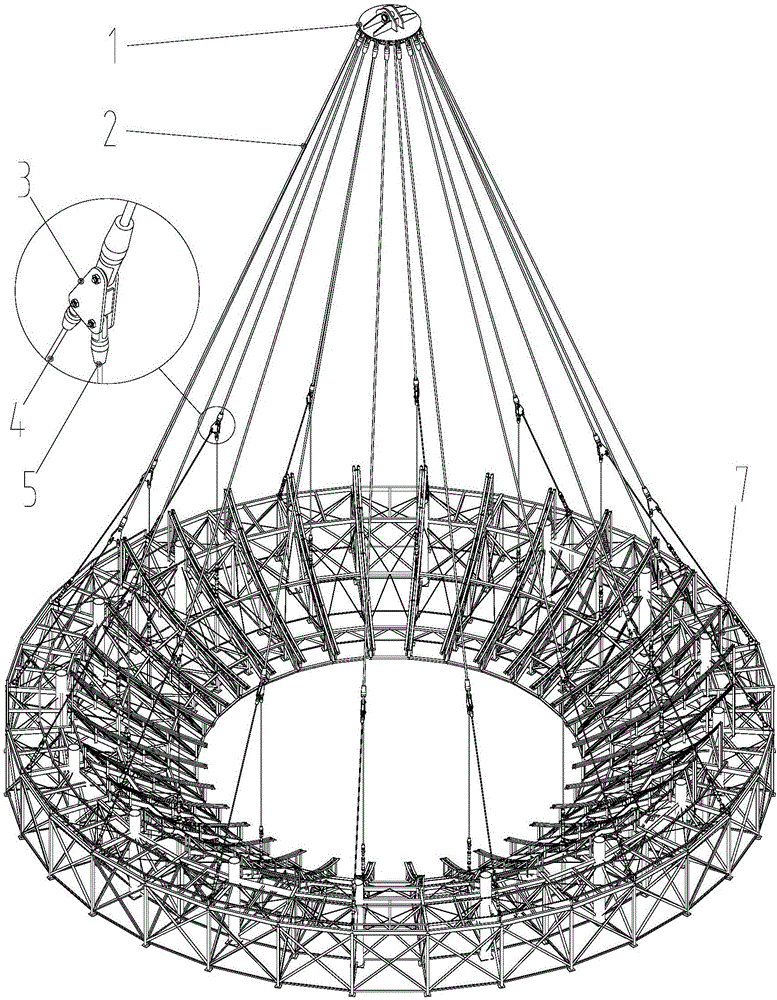

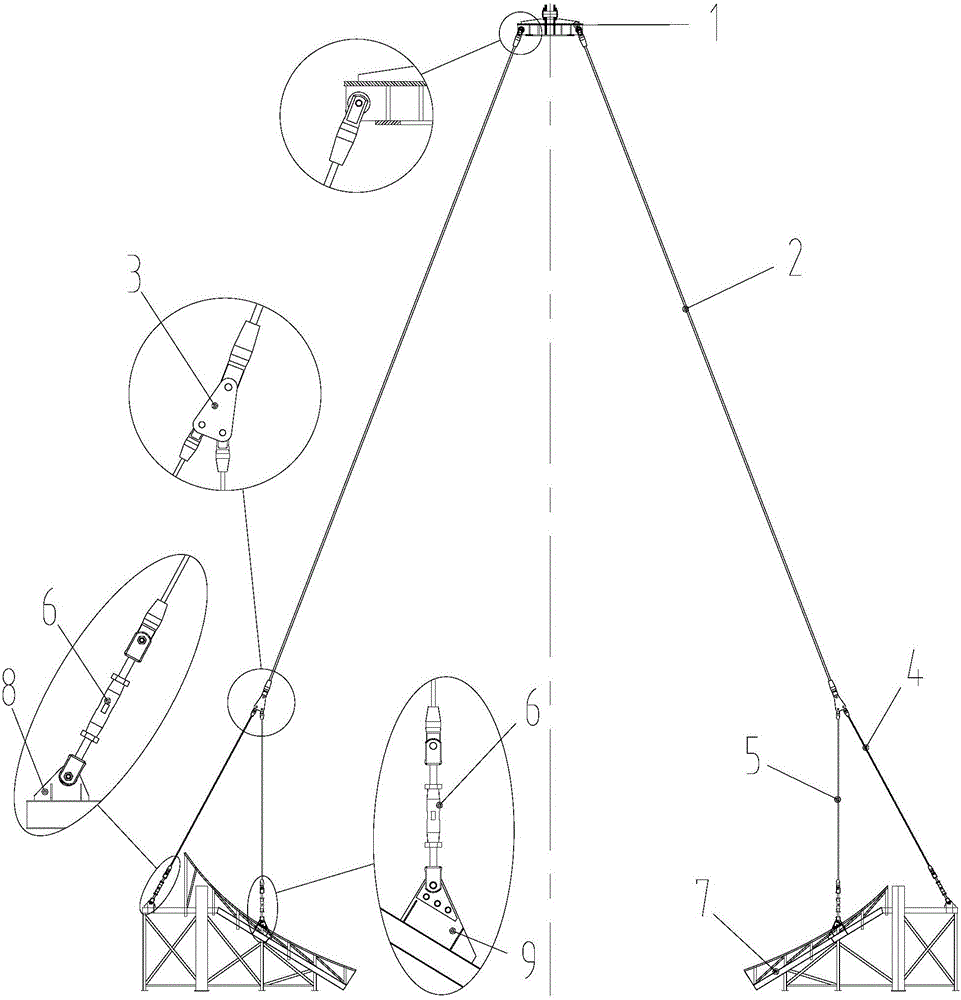

[0046] This embodiment discloses a special sling for a nuclear power plant CR10 and steel bar combination module, such as Figure 1-7 As shown, it includes a transition beam 1 and a plurality of sling units connected to the transition beam respectively; An adjustable pull rod 6; one end of the main sling 2 is fixed on the transition beam; the other end of the main sling 2, the outer auxiliary sling 4 and the inner auxiliary sling 5 are respectively connected with the sling distributor 3, and the outer One end of the auxiliary sling 4 away from the sling distributor 3 is connected to an adjustable pull rod 6 , and the end of the inner auxiliary sling 5 away from the sling distributor 3 is connected to another adjustable tie rod 6 .

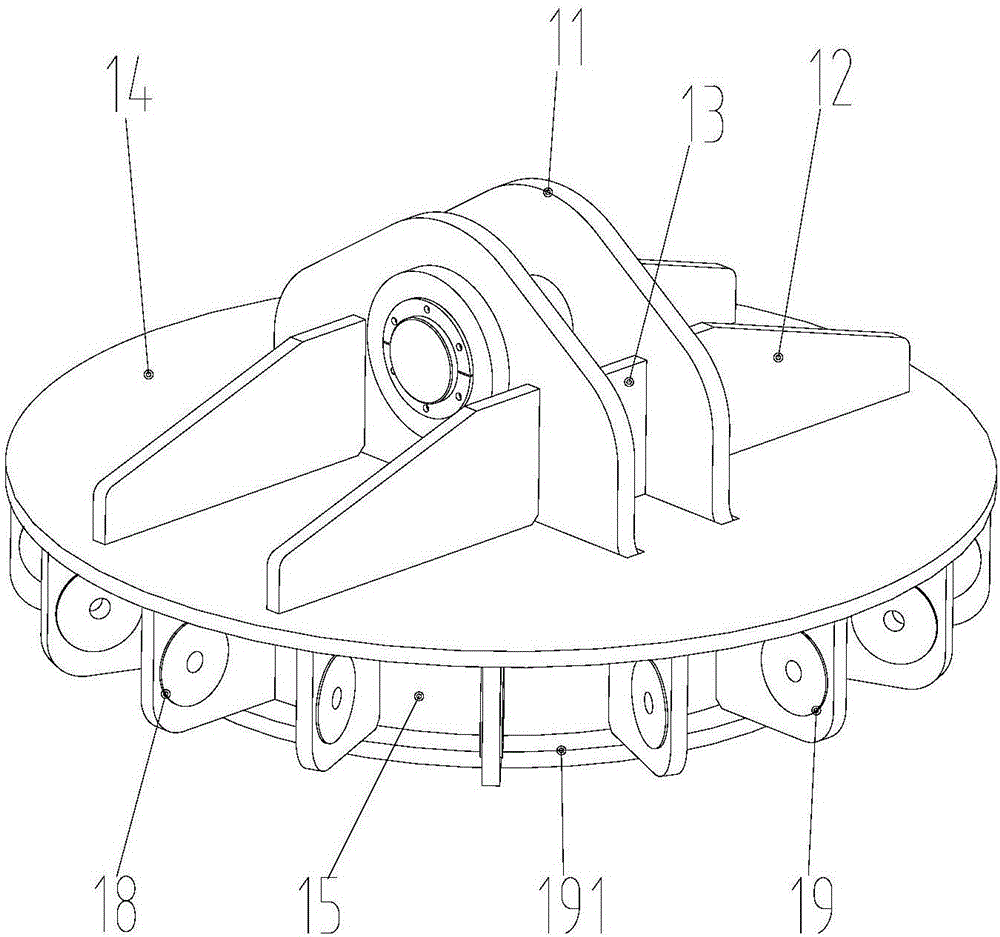

[0047] The transition beam 1 is circular and consists of an upper lug plate 11, a first rib plate 12, a second ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com