A mobile automatic sand loading machine rotary mechanism

A slewing mechanism, mobile technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing the wall thickness of the slewing mechanism, small belt extension distance, small rotation angle, etc., to increase the key extension Effect of increasing distance, increasing service life, and increasing extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

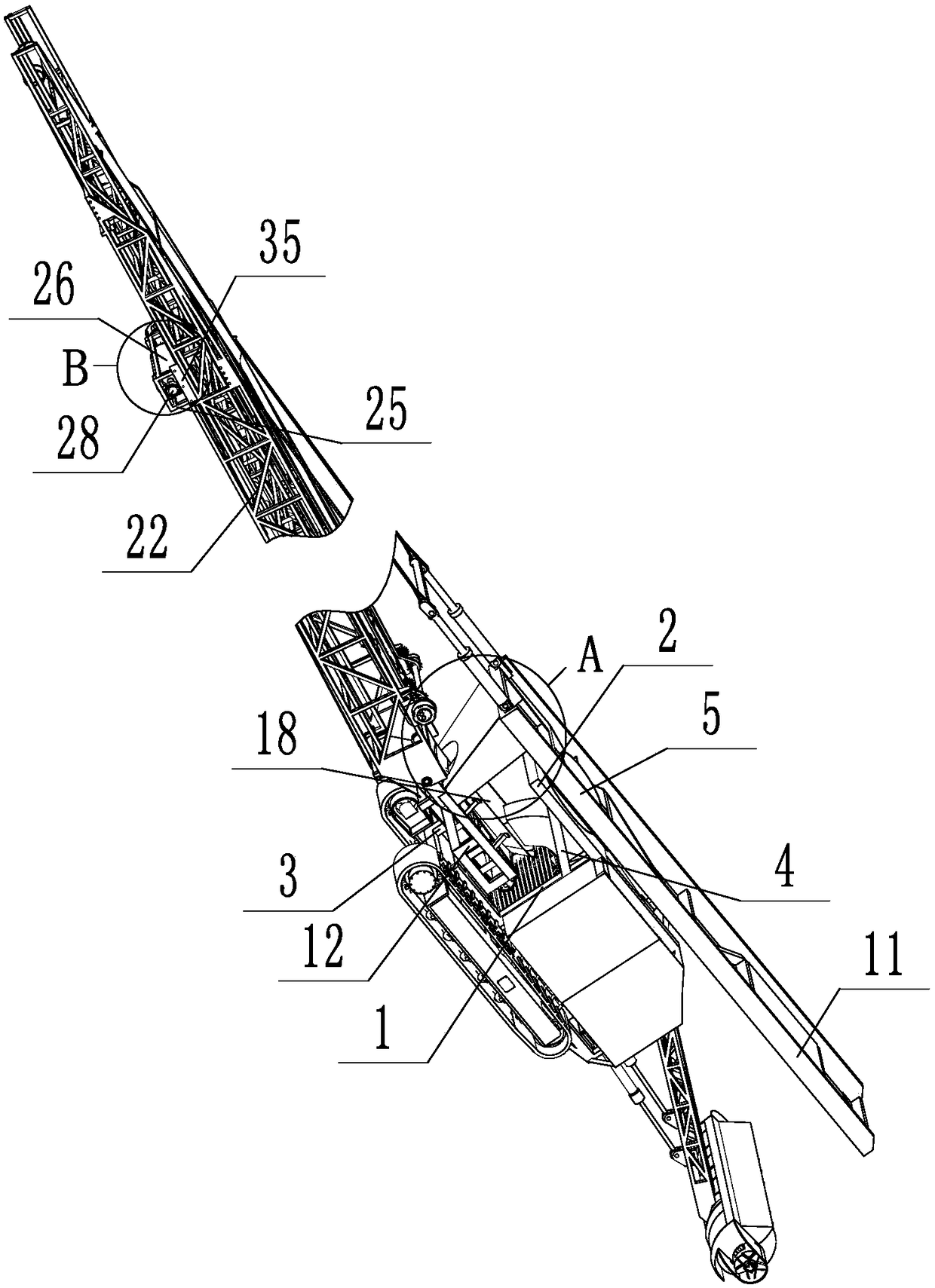

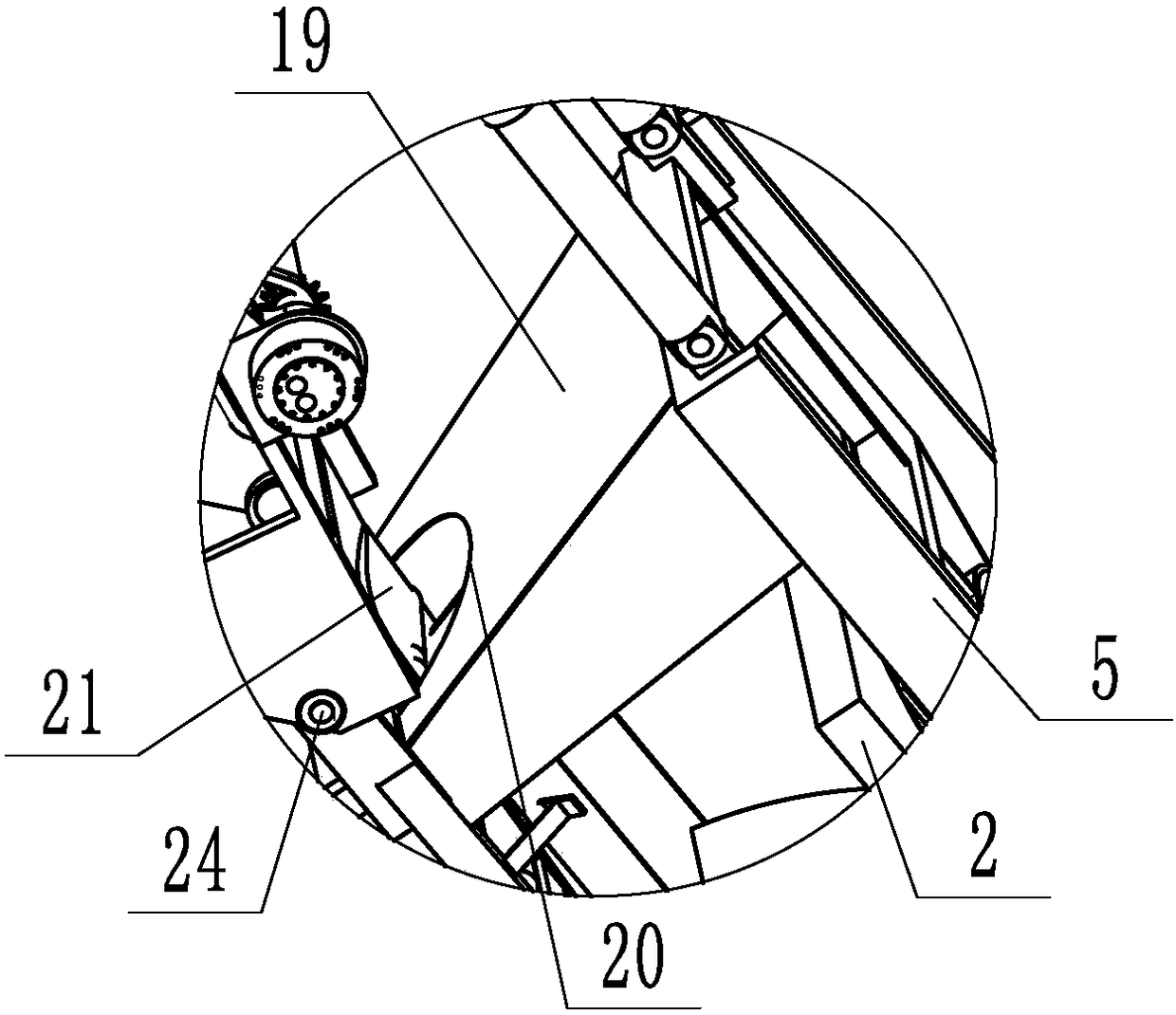

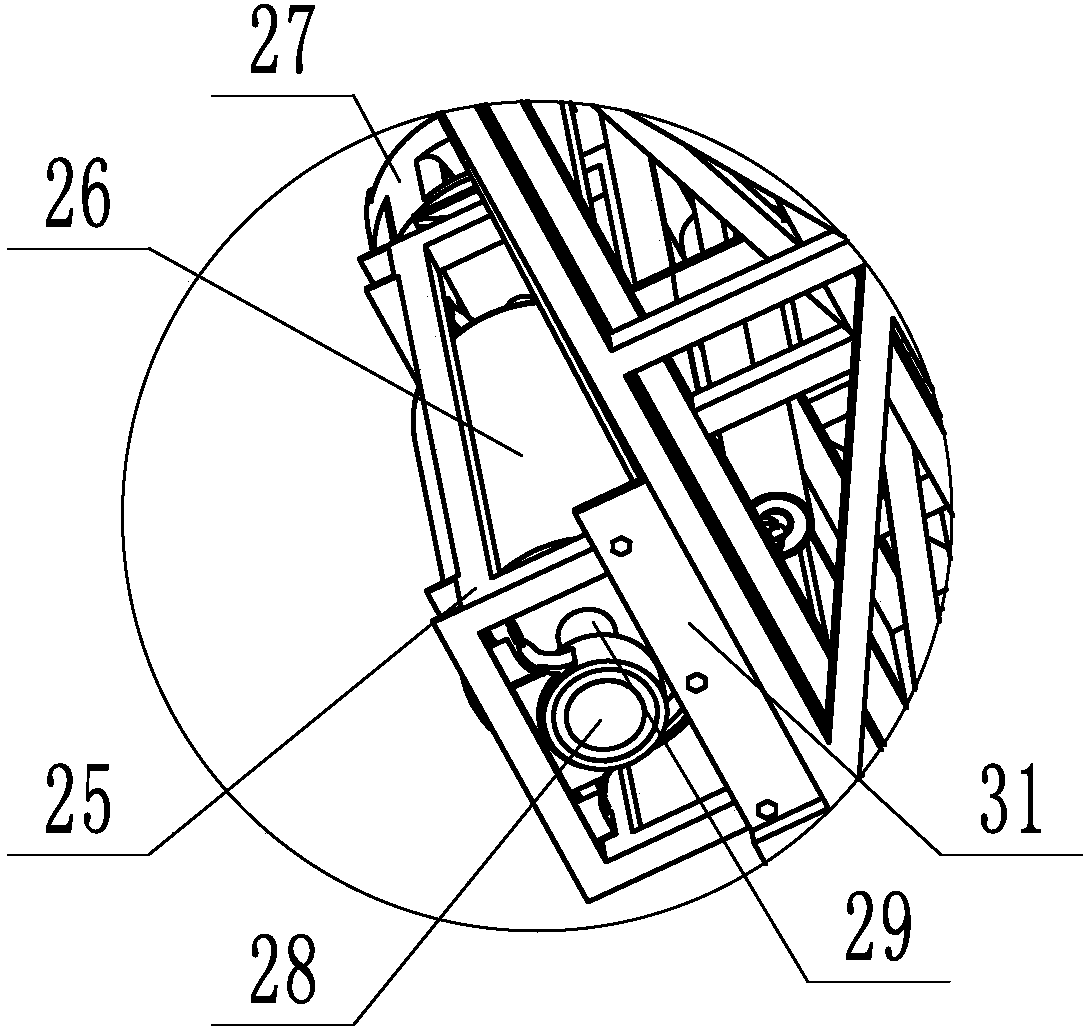

[0031] according to Figure 1 to Figure 7 As shown, a mobile automatic sand loading machine rotary mechanism includes a rotary part, a belt 21, a belt bracket 22 and a support frame 1, the belt 21 is installed in the belt bracket 22, and the belt bracket 22 is located in front of the support frame 1. The upper end of the support frame 1 is provided with an upper slewing support 2, the lower end of the support frame 1 is provided with a lower slewing support 3, the right end of the upper slewing support 2 is welded together with the main body of the support frame 1, and the upper end of the upper slewing support 2 is a flat plate. A through hole is provided at the middle position, and a support rod 4 is provided between the upper slewing support 2 and the main body of the support frame 1. The angle formed between the support rod 4 and the main body of the support frame 1 is 45°, and the upper end of the support rod 4 and the upper rotary The lower end surface of the support 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com