Goods delivering frame for vertical lifting delivering system

A technology of vertical lifting and racking, applied in conveyors, transportation and packaging, etc., can solve problems such as manual delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

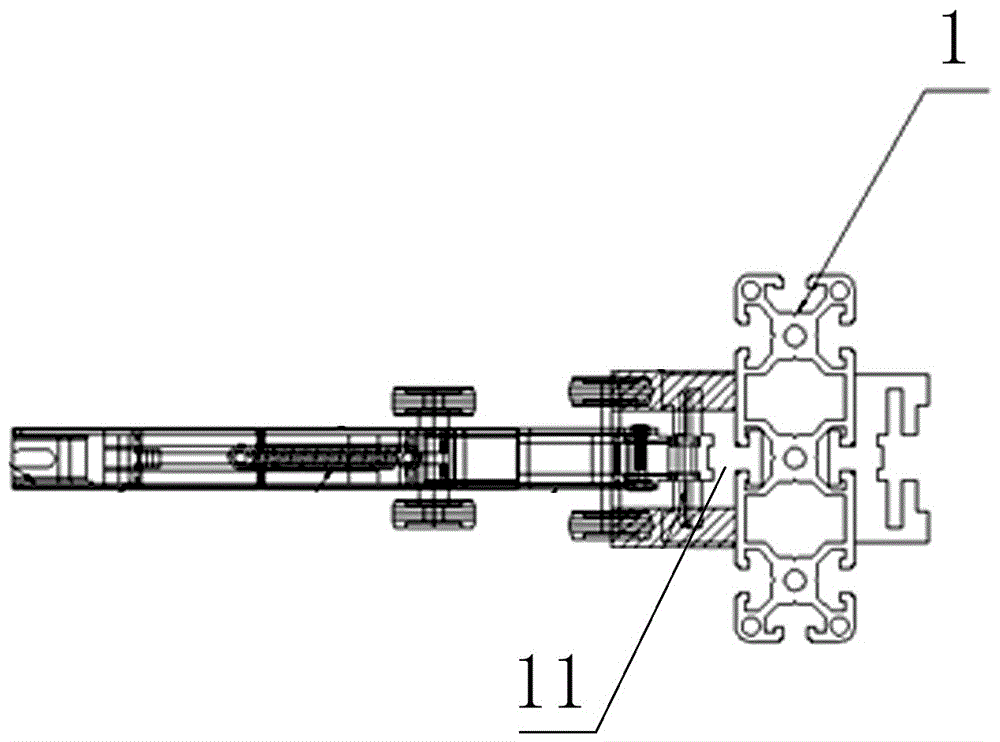

[0028] The invention discloses a delivery rack for a vertical lifting and delivery system, which is different from the prior art in that it includes vertically distributed uprights 1, and power cycle chains 2 are longitudinally distributed along the upright direction at the upright 1, and the delivery rack One end of the 3 is fixedly connected to the power cycle chain 2, and the other end of the delivery rack 3 is suspended. A movable tongue 4 is arranged on the upper part of the delivery rack 3, and a group of movable tongue rollers 5 are arranged on the lower edge of the side of the movable tongue 4 near the column. Delivery rack 3 is provided with a delivery mouth 6 near the top of the free end, and the lower edge of delivery mouth 6 one end is connected with delivery rack 3 by a delivery mouth rotating shaft 7, and delivery mouth 6 one end forms an impact position 8 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com