An egg automatic palletizing robot

A technology of robots and eggs, which is applied in packaging eggs, food packaging, dairy products packaging, etc., can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments. The exemplary implementation cases and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

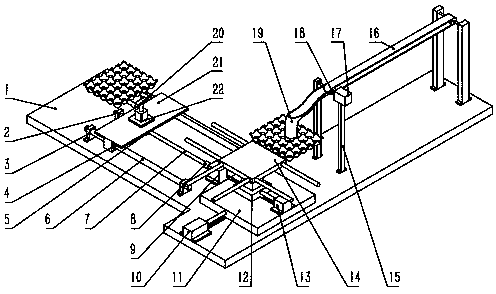

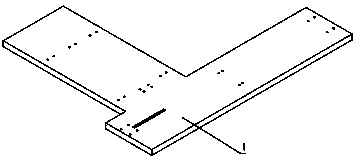

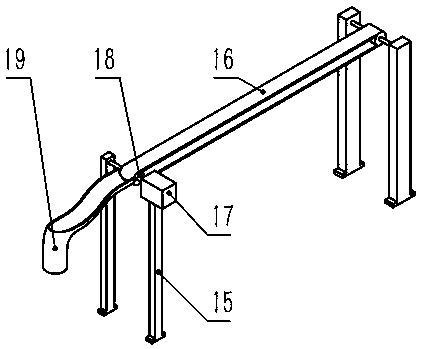

[0012] Such as figure 1 , 2 , 3, 4, and 5, an egg automatic palletizing robot, including a base 1, a lead screw support 2, four optical axis supports 3, two linear bearings 4, a lead screw nut 5, and two optical axes 6. Lead screw 7, coupling 8, first stepping motor 9, first linear motor 10, sliding plate 11, second stepping motor 12, second linear motor 13, turret 14, four pillars 15 , the conveyor belt 16, the third stepper motor 17, two rollers 18, the supporting opening 19, the supporting bracket 20, the supporting base plate 21, the third linear motor 22, and it is characterized in that: the four screw supports described 2 fixedly installed on the base 1; the optical axis support 3 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com