Camera fixing support used for unmanned aerial vehicle

A fixed camera and unmanned aerial vehicle technology, which is applied to motor vehicles, aircraft parts, aircraft, etc., can solve the problems of cameras not working properly, unable to complete shooting tasks, and materials with good thermal insulation performance, so as to achieve simplified shooting preparations and cooling effects Visible, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings:

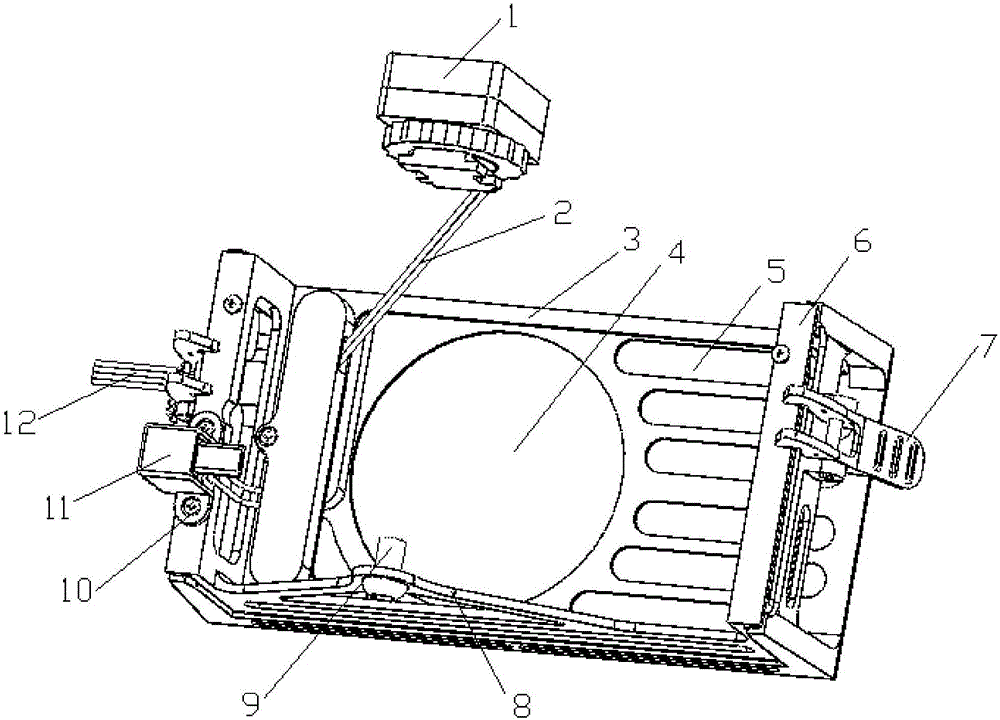

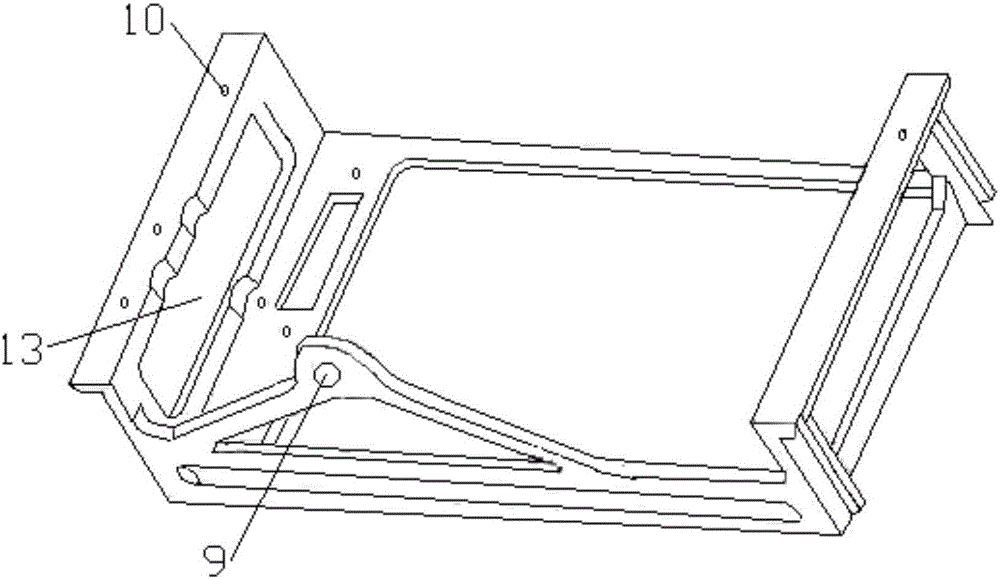

[0025] A camera fixing frame for unmanned aerial vehicles, comprising a base 3, a frame 6 installed inside the base 3, and a locking structure 7 connecting the base 3 and the frame 6; a rectangular window is opened on the front of the frame 6, and the frame 6 There are rectangular holes 13 on the left and right side walls, the top of the side wall of the frame 6 protrudes outwards, the protrusions on the top of the side wall outwards are provided with screw holes 10, and the bottom of the frame 6 is provided with a support plate 8 , The support plate 8 is provided with a camera fastening screw hole 9; the front of the base 3 is provided with a lens hole 4, the front of the base 3 is provided with an escape hole 5, and both sides of the base 3 are provided with data ports 14. A locking chuck 15 is provided on the outer sides of both sides of the base 3, and a locking structure 7 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com