Method for making fixing device for bicycle frame pipe fitting welding

A pipe fitting welding and fixing device technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as affecting the health of workers and low production efficiency of bicycle racks, avoiding manual fixing and liberating labor. , to achieve the effect of mechanical fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail according to the accompanying drawings and specific embodiments.

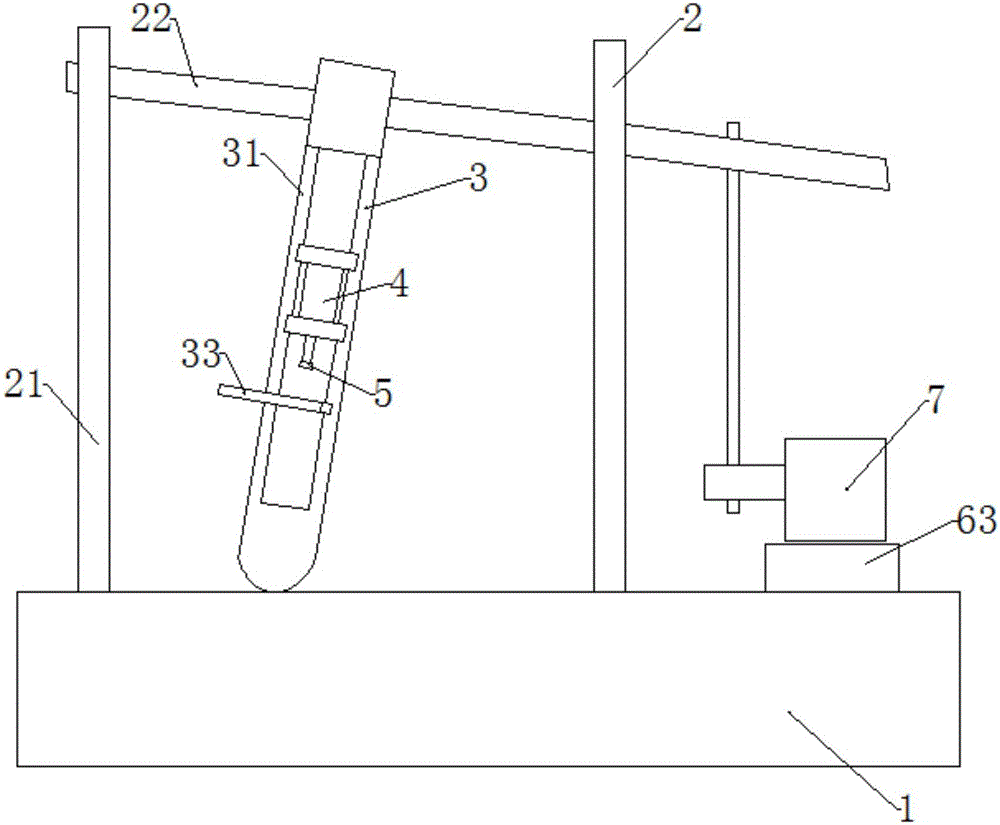

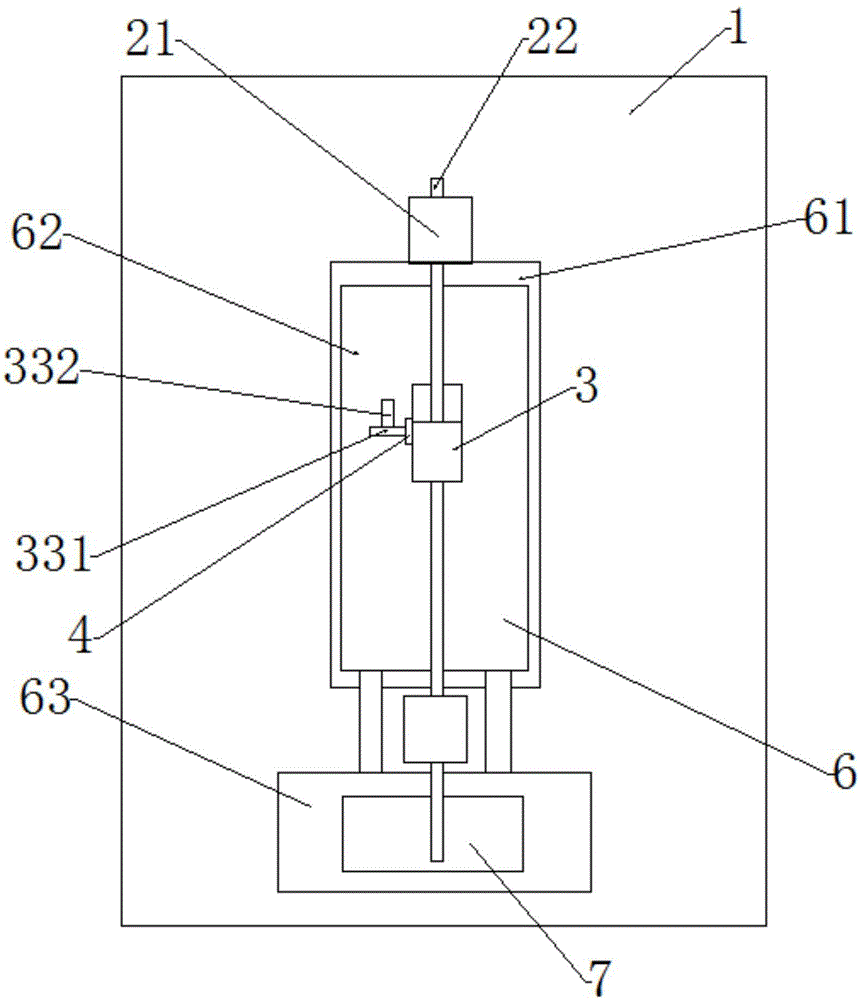

[0027] like Figures 1 to 3 As shown, the present invention includes a base 1, a support 2, a cylinder support 3, a cylinder 4 and a clamping plug 5;

[0028] The support 2 includes two vertical support vertical beams 21 relatively fixed on the base 1 and a threaded rod 22 rotatably fixed on the top of the two support vertical beams 21. The threaded rod 22 is inclined downward at a certain angle from the left end to the right end;

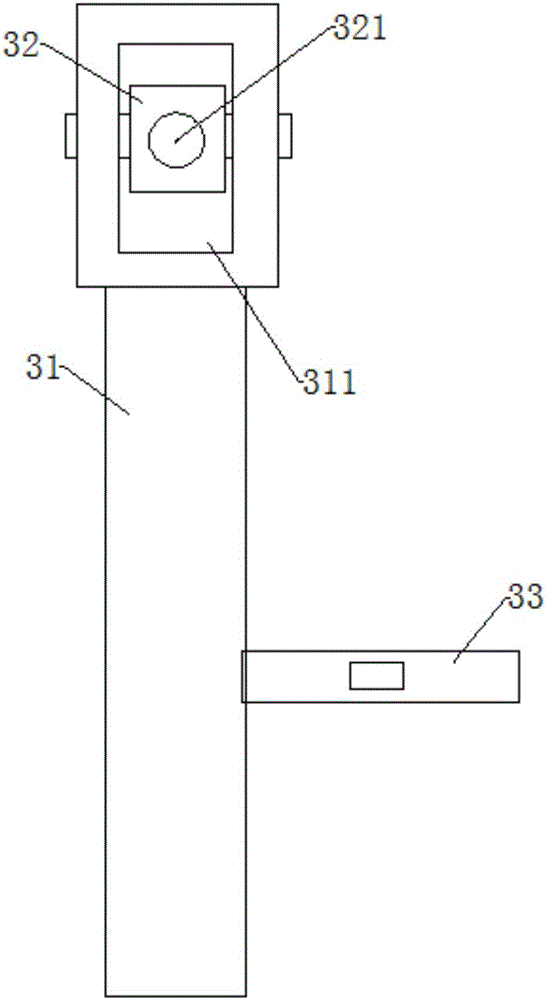

[0029] The cylinder bracket 3 includes a support rail 31, an angle adjustment mechanism 32 and a support bracket 33 fixed on the support rail 31;

[0030] The upper end of the support rail 31 is provided with a mounting groove 311, and the angle adjustment mechanism 32 is rotatably fixed in the installation groove 311, and the rotation axis of the angle adjustment mechanism 32 is perpendicular to the vertical plane where the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com