Welding method and welding device for storage tank inversion method

A technology of welding method and flip-chip method, applied in welding equipment, welding accessories, applications, etc., can solve the problems of low welding efficiency, high construction cost, large equipment volume, etc., and achieve the effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Such as figure 1 and figure 2 Shown, the welding method that the present invention is used for storage tank flip-chip method comprises the following steps:

[0026] a. Prepare a submerged arc welding trolley 1: the submerged arc welding trolley 1 includes a body, two sets of wheels symmetrically arranged at the bottom of the body and a mounting bracket arranged on the top of the body. The mounting bracket includes a horizontal beam 2-1 and The column 2-2 arranged vertically, the beam 2-1 and the column 2-2 are vertically connected. Each axial end of each wheel of the submerged arc welding trolley is provided with a limiting ring whose outer diameter is larger than the outer diameter of the wheel, and the limiting ring is integrally formed with the corresponding end of the wheel.

[0027] b. A welding wire reel 3 and a control box 4 for controlling the welding operation are installed at one end of the beam 2-1, and a welding tip adjustment tube 5 is rotatably connecte...

Embodiment 2

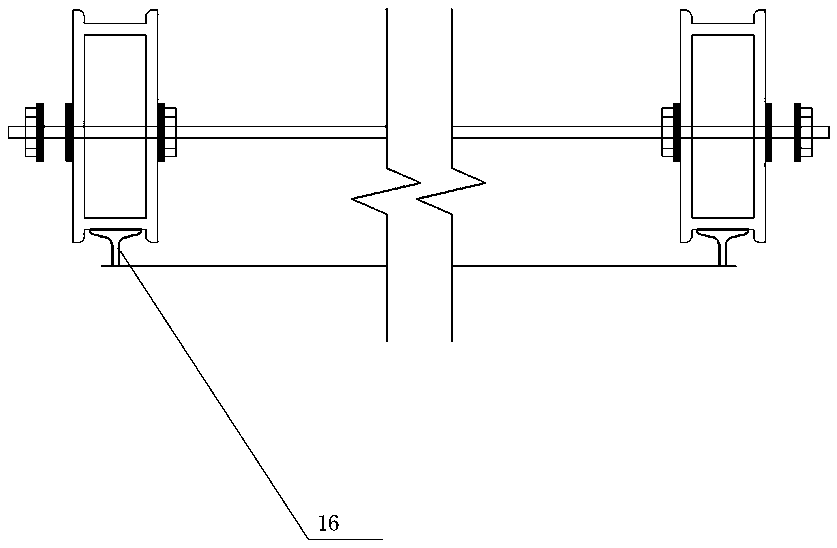

[0033] Such as figure 1 and figure 2 As shown, the welding device used in the storage tank flip-chip method of the present invention includes a submerged arc welding trolley 1, a support frame 13 arranged in a circumferential direction on the outside of the storage tank 12, and a welding machine walking track 16 installed on the top of the support frame 13, The submerged arc welding trolley 1 includes a vehicle body, two sets of wheels symmetrically arranged at the bottom of the vehicle body and a mounting bracket arranged on the top of the vehicle body. The mounting bracket includes a horizontal beam 2-1 and a vertical column 2-2, and the beam 2- 1 is vertically connected with column 2-2. Each axial end of each wheel of the submerged arc welding trolley is provided with a limiting ring whose outer diameter is larger than the outer diameter of the wheel, and the limiting ring is integrally formed with the corresponding end of the wheel.

[0034] One end of the crossbeam 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com