A CNC gear hobbing machine

A technology of gear hobbing machine and main engine, which is applied in the direction of gear cutting machine, gear teeth, mechanical equipment, etc. It can solve the problems of uncompact base structure, large base area, and poor shock resistance, and achieve excellent shock resistance, large driving torque, and The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

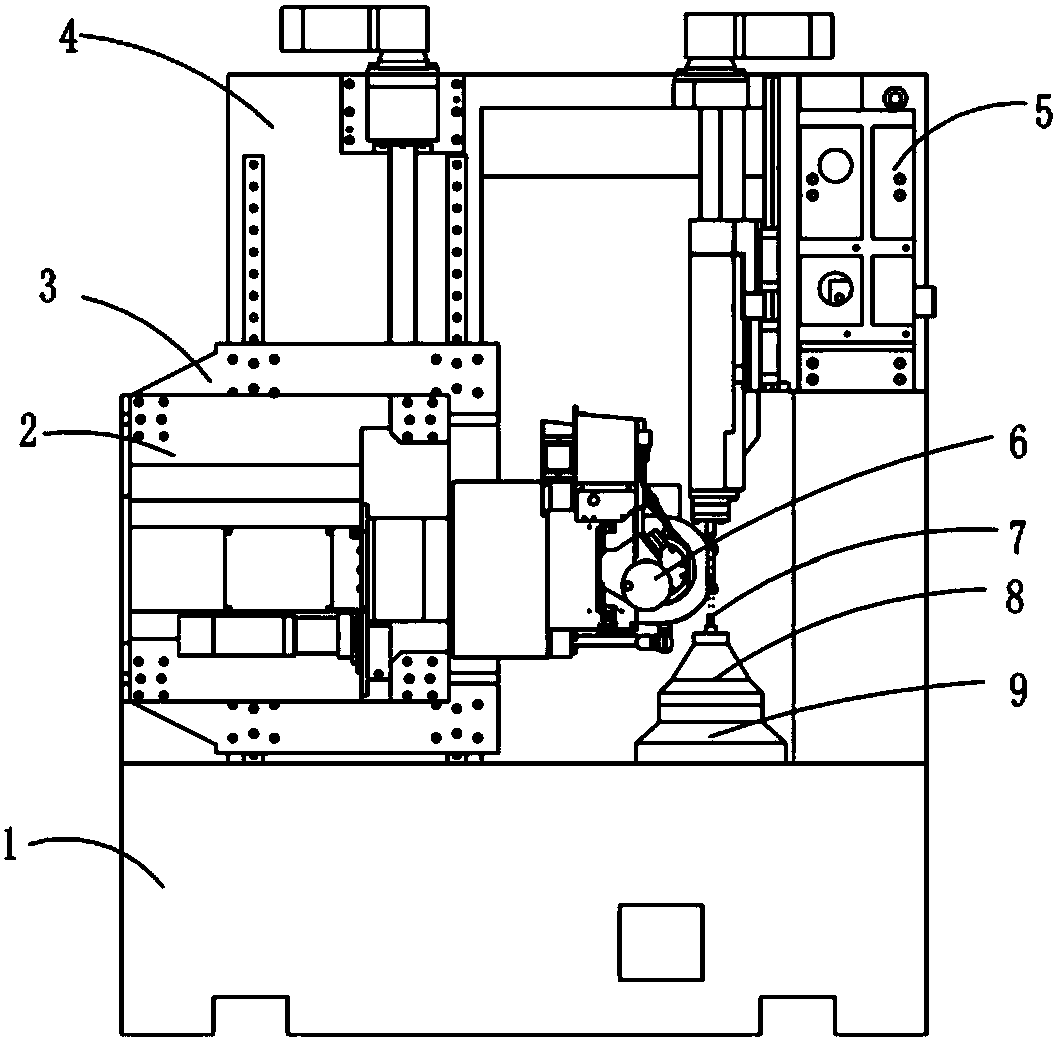

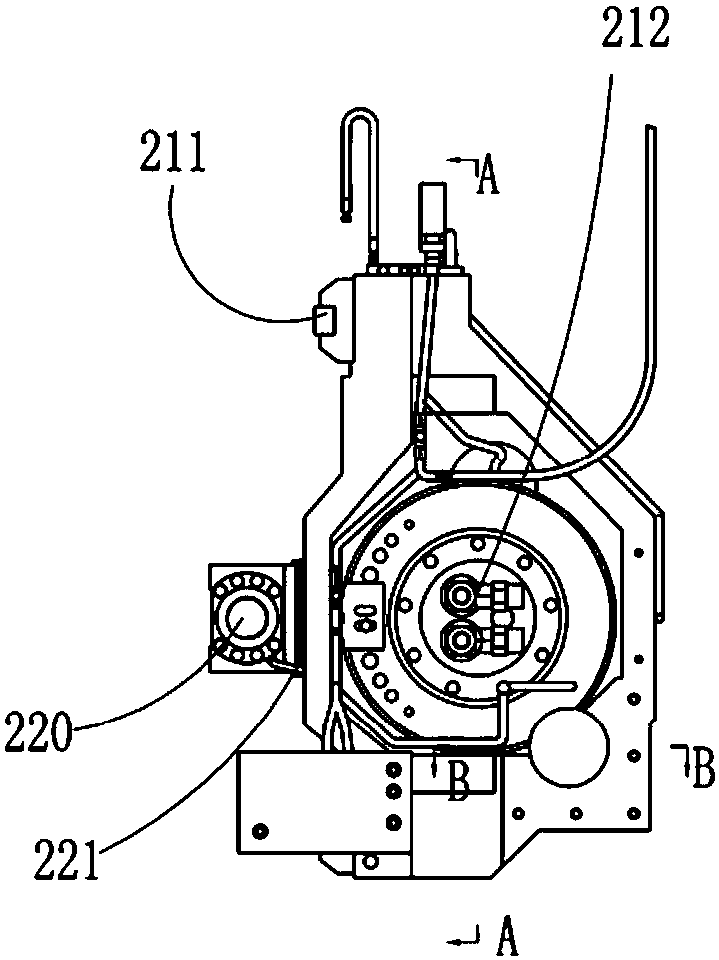

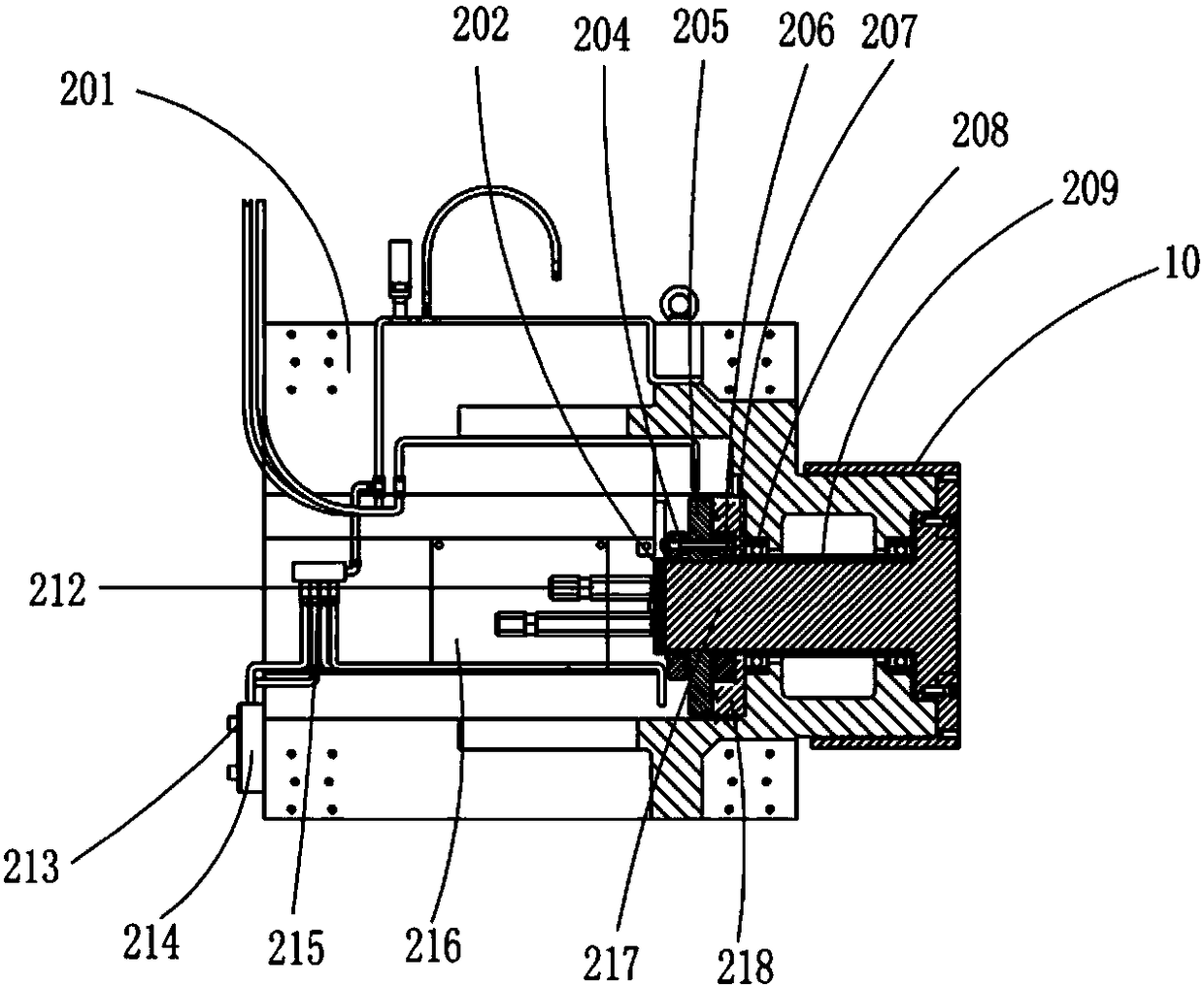

[0046] see attached Figure 1~17 , A CNC gear hobbing machine, the main machine is in a vertical layout, the main machine includes a bed 1, a base 2, a slide plate 3, a column 4, a tailstock 5, a tool rest 6, a workpiece 7, a workpiece fixture 8 and a workbench 9, The column 4 and the bed 1 are in an L-shaped rigid connection structure; the base 2, the slide plate 3, the tailstock 5, and the tool rest 6 are respectively installed on the column 4, and are arranged in a square shape on the column; the base The right side of 2 is connected with the tool rest 6 through the outer casing 10; the nut bracket on the back side of the base 2 is connected with the ball screw and the nut on the slide plate 3, and the rotation of the ball screw drives the base 2 and the tool rest 6 to make a horizontal direction. move; realize the radial feed of the X-axis of the machine tool; the slide plate 3 moves vertically up and down on the column 4 to realize the vertical feed of the Z-axis of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com