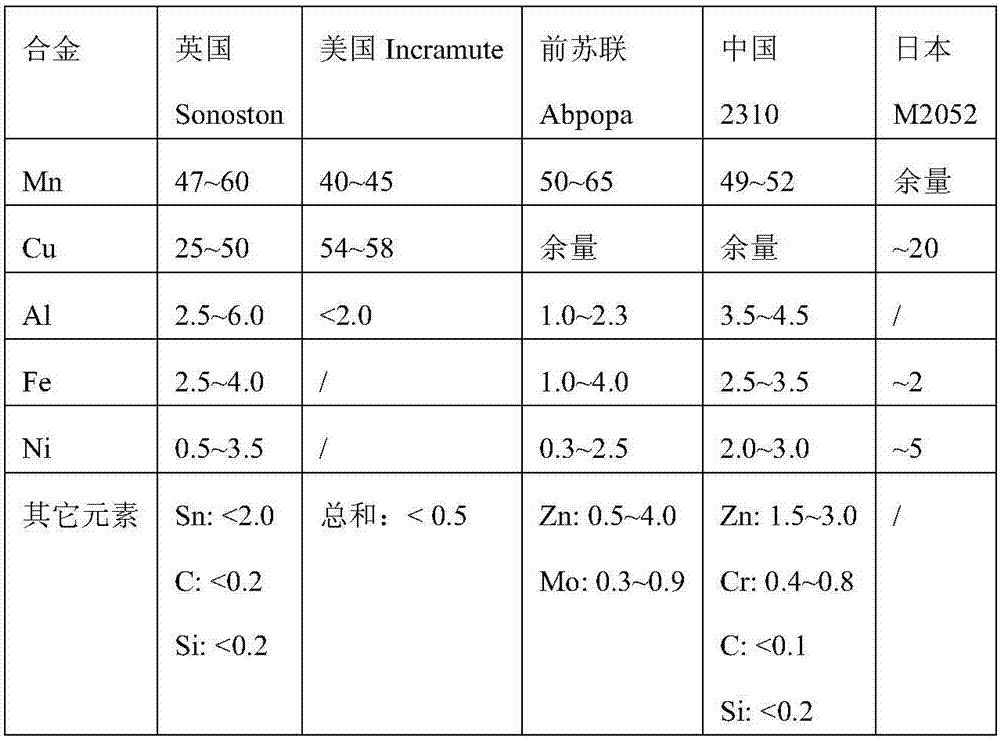

A Process for Improving the Uniformity of Microstructure and Properties of Manganese Copper Sintered Damping Alloy

A technology of damping alloy and uniformity, which is applied in the field of atmosphere sintered porous structure manganese-copper high damping alloy, which can solve the problems of residual oxygen embrittlement in the alloy and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

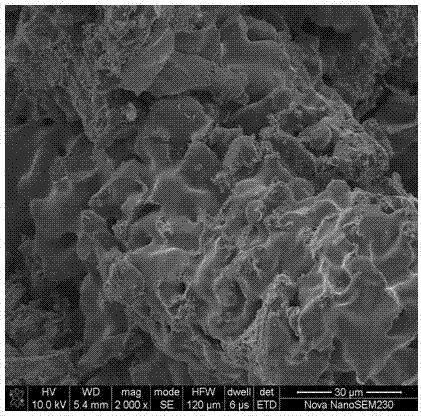

[0032] Manganese, copper, nickel, aluminum, tin, carbon, silicon and other powders and copper oxalate are batched according to the ingredients in Example 1 of Table 2. Place the prepared powder in a ball mill tank for dry milling, and the ball milling time is about 2 hours until the powder is uniform.

[0033] Table 2 The composition range (mass percentage) of the manganin-copper damping alloy of the embodiment

[0034]

[0035] * is the content of Cu element obtained by decomposing copper oxalate

[0036] The mixed powder was pressed into a green compact under a pressure of 600 MPa using a pressing die.

[0037] Under the protection of flowing dry hydrogen, pyrolysis, reduction and sintering, the specific steps are 450°C for 1 hour; 800°C for 1 hour; and then 920°C for 2 hours. Cool in the furnace. The sintered manganese copper is obtained through solid solution and aging treatment.

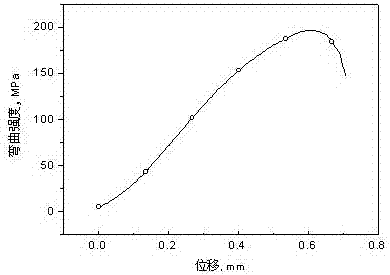

[0038] The properties of the obtained sintered compacts are listed in Table 3.

[00...

Embodiment 2

[0043] Powders such as manganese, copper, nickel, aluminum, tin, carbon, silicon and copper oxalate are batched according to the ingredients in Example 2 of Table 2. Put the prepared powder into a ball mill tank for dry milling, and the ball milling time is about 3 hours until the powder is uniform.

[0044] The mixed powder was pressed into a green compact under a pressure of 300 MPa using a circular die.

[0045] Pyrolysis, reduction and sintering under the protection of flowing dry hydrogen, the specific steps are 330°C for 4 hours; 600°C for 4 hours; 850°C for 4 hours; heating rate 5°C / min. With the cooling of the furnace, the sintered manganese copper is subjected to solid solution and aging treatment to obtain the product. The properties of the obtained sintered compacts are listed in Table 3.

Embodiment 3

[0047] Manganese, copper, nickel, aluminum, molybdenum, zinc powder and copper oxalate are batched according to the ingredients in Table 2 Example 3. Put the prepared powder into a ball mill tank for dry milling, and the ball milling time is about 0.5h until the powder is uniform.

[0048] The mixed powder was pressed into a compact under a pressure of 500 MPa using a circular pressing die.

[0049] Pyrolysis, reduction and sintering under the protection of flowing dry hydrogen, the specific steps are 400°C for 2 hours; 700°C for 2 hours; then 920°C for 2 hours, and the heating rate is 8°C / min. With the cooling of the furnace, the sintered manganese copper is subjected to solid solution and aging treatment to obtain the product. The properties of the obtained sintered compacts are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com