Hollow plain gold jewelry Lulu Tong manufacturing method

A production method, Passepartout's technology, is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., which can solve the problems of low production efficiency, obvious seams, and unnatural patterns, so as to reduce production costs and improve Production efficiency, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

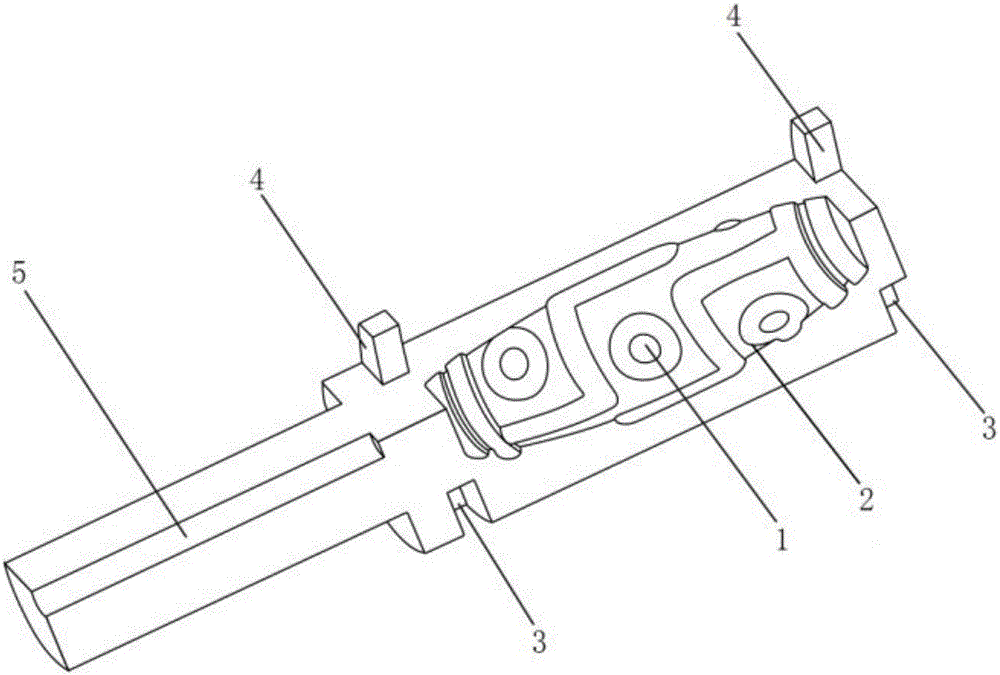

[0021] see Figure 1 to Figure 4 , the embodiment of the present invention includes:

[0022] A kind of preparation method of plain gold hollow passepartout, the steps are as follows:

[0023] (1) Use an engraving machine to carve out the mold wax plate;

[0024] (2) Make the corresponding silver mold through the mold wax plate;

[0025] (3) Put the calculated weight of wax pellets into a sealable silver mold and heat them.

[0026] (4) Put the heated silver mold on the electric drill and rotate it, and use the rotating centrifugal force to evenly distribute the melted wax liquid on the inner wall of the silver mold. After the mold is cooled slowly, the wax liquid solidifies to obtain a brigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com