Core box and method for producing integrated sand cores

A sand core and conjoined technology, applied in casting and forming equipment and other directions, can solve the problems of poor fixation of the sand core, defects of sand inclusion in castings, restricting production efficiency, etc., to avoid the problem of sand inclusion, reduce casting defects, and avoid choking fire. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The illustrated embodiments are disclosed with reference to the drawings. It should be understood, however, that the disclosed embodiments are merely embodiments that may be shown in various and alternative forms. The figures are not necessarily to scale and some features may be exaggerated or minimized to show details of particular components. Specific structural and functional details disclosed are not to be interpreted as limiting, but as a representative basis for teaching one skilled in the art how to practice the present disclosure.

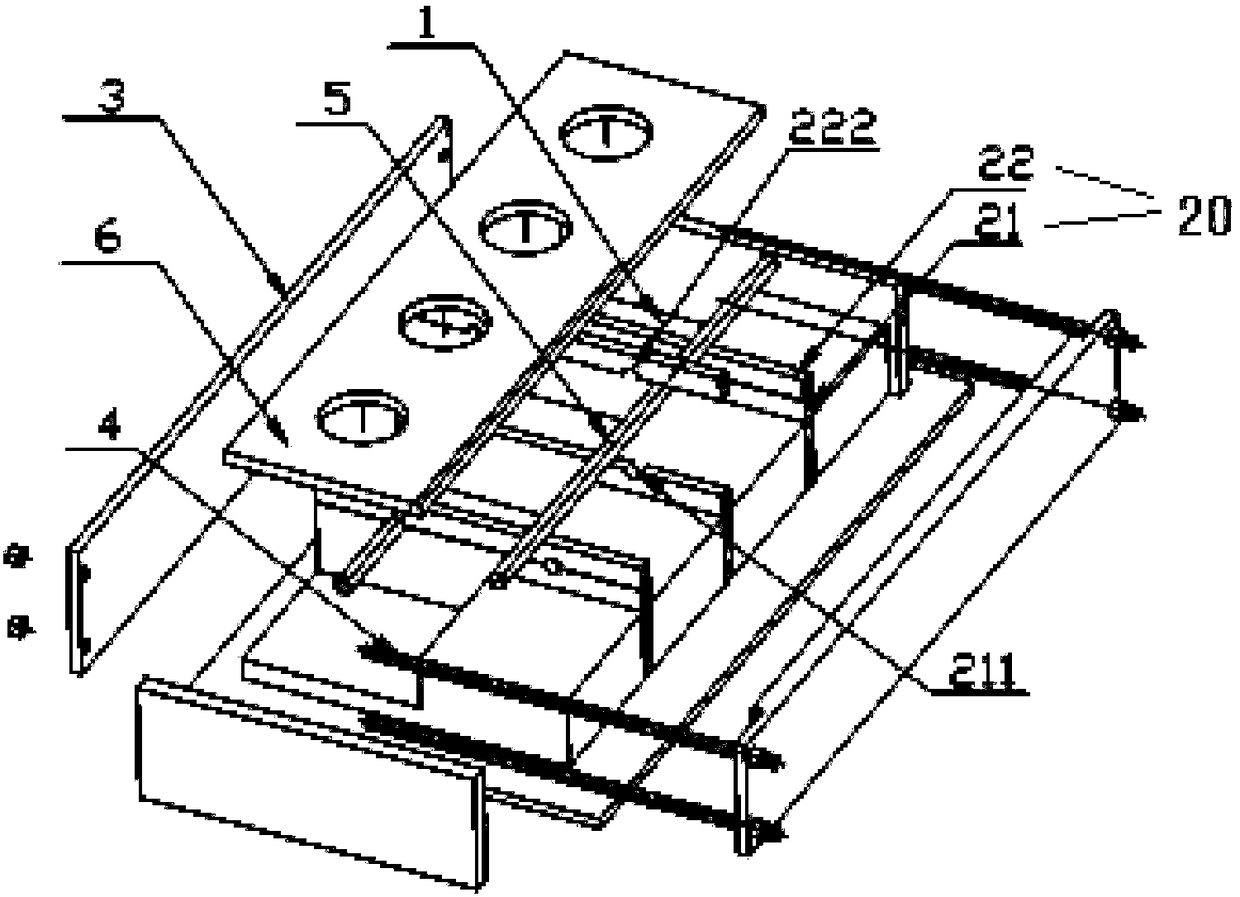

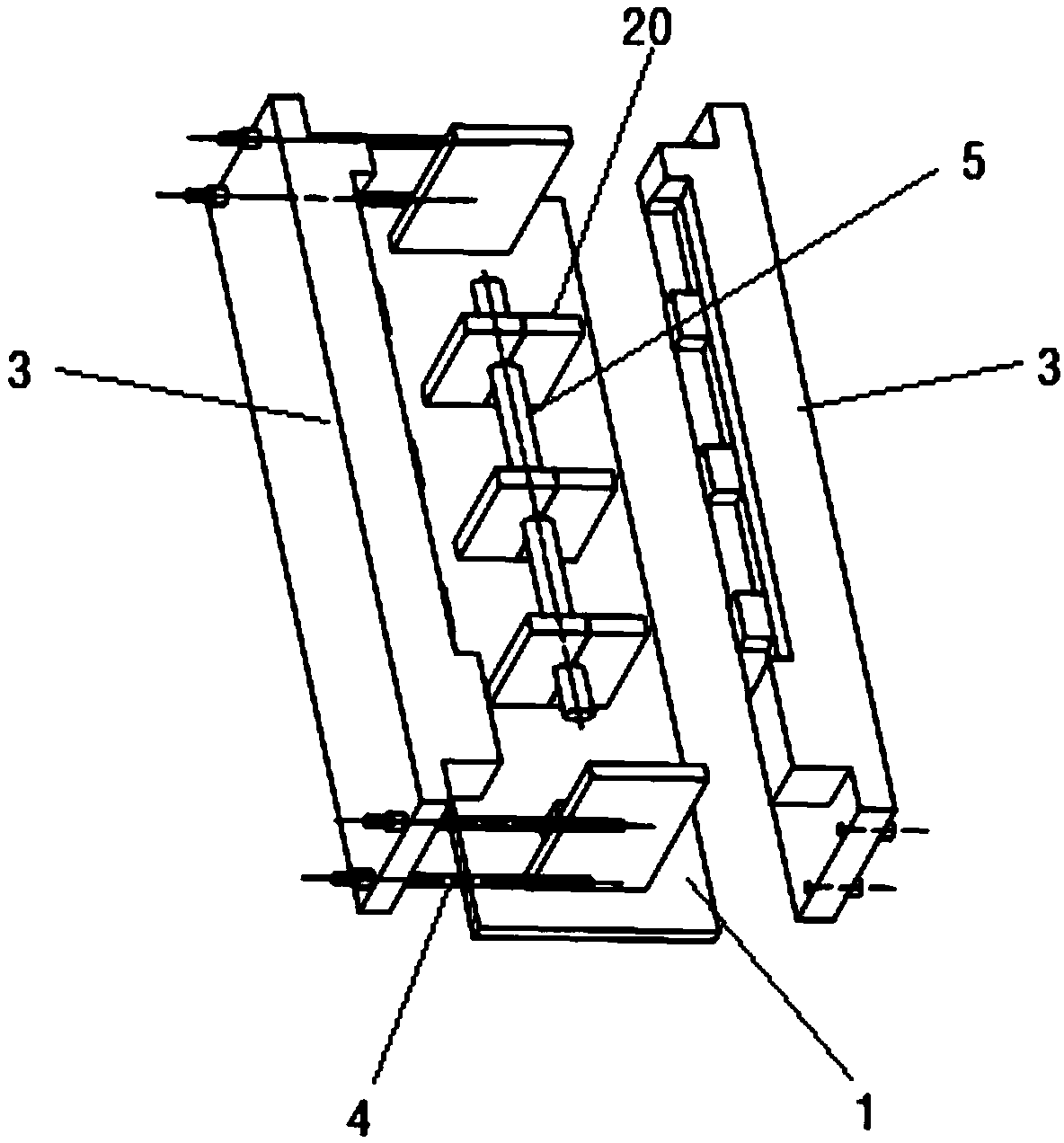

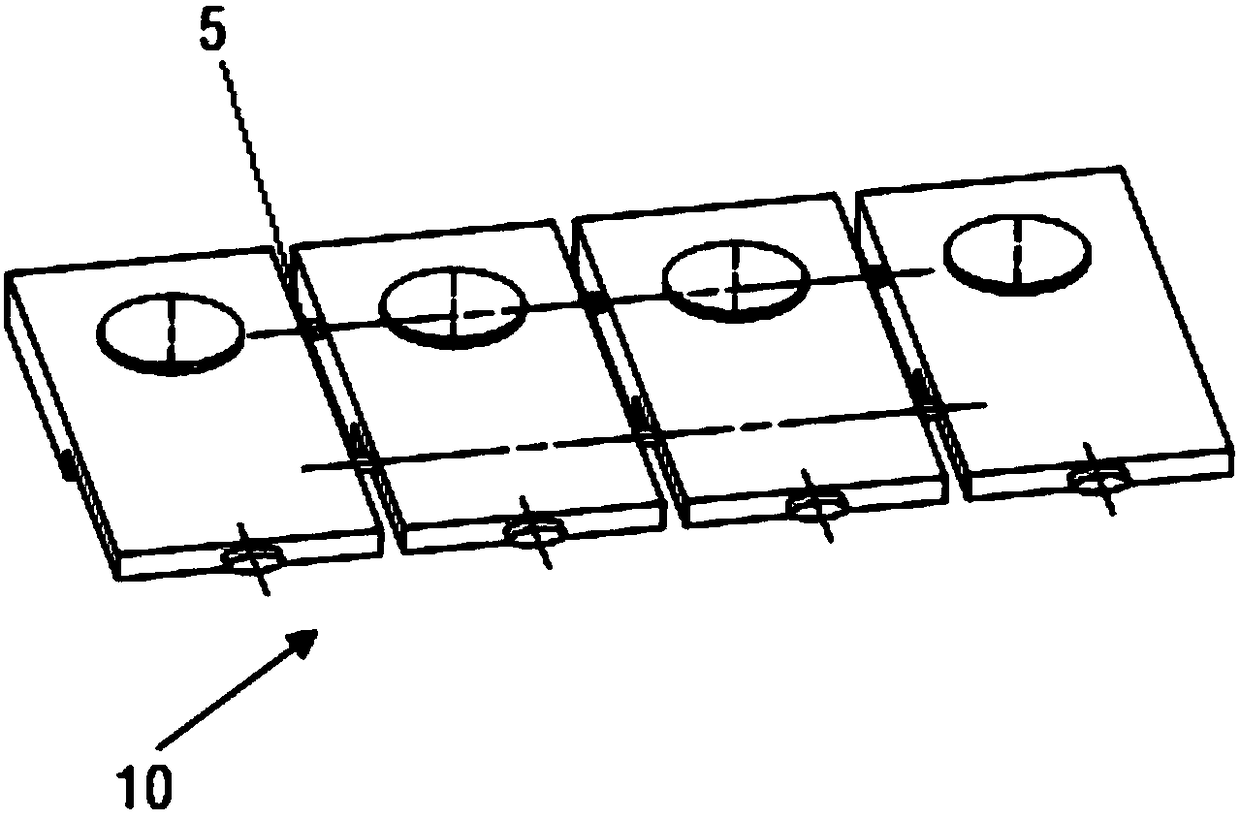

[0024] refer to Figure 1 to Figure 2 , the present invention provides a core box for producing conjoined sand cores, comprising: a base plate 1; at least one intermediate plate 20 vertically connected to the base plate 1; a split core plate detachably connected around the periphery of the intermediate plate 20 and the base plate 1 3. The core bone 5 that passes through at least one intermediate plate 20 in sequence and is detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com