Reverse deformation shaping tool for outward turnover of tower drum flange of wind generating set and method for reverse deformation shaping tool

A wind turbine, anti-deformation technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of not guaranteeing the qualified flange repair, waste of welding materials and labor, long flame baking cycle, etc. Eliminate hidden quality risks, reduce shaping time, reduce material and labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

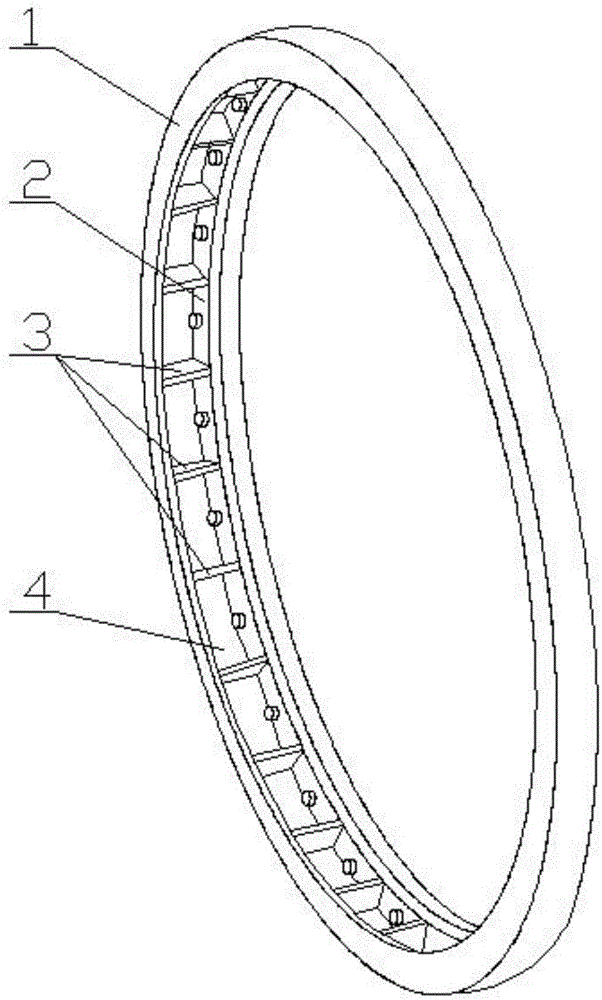

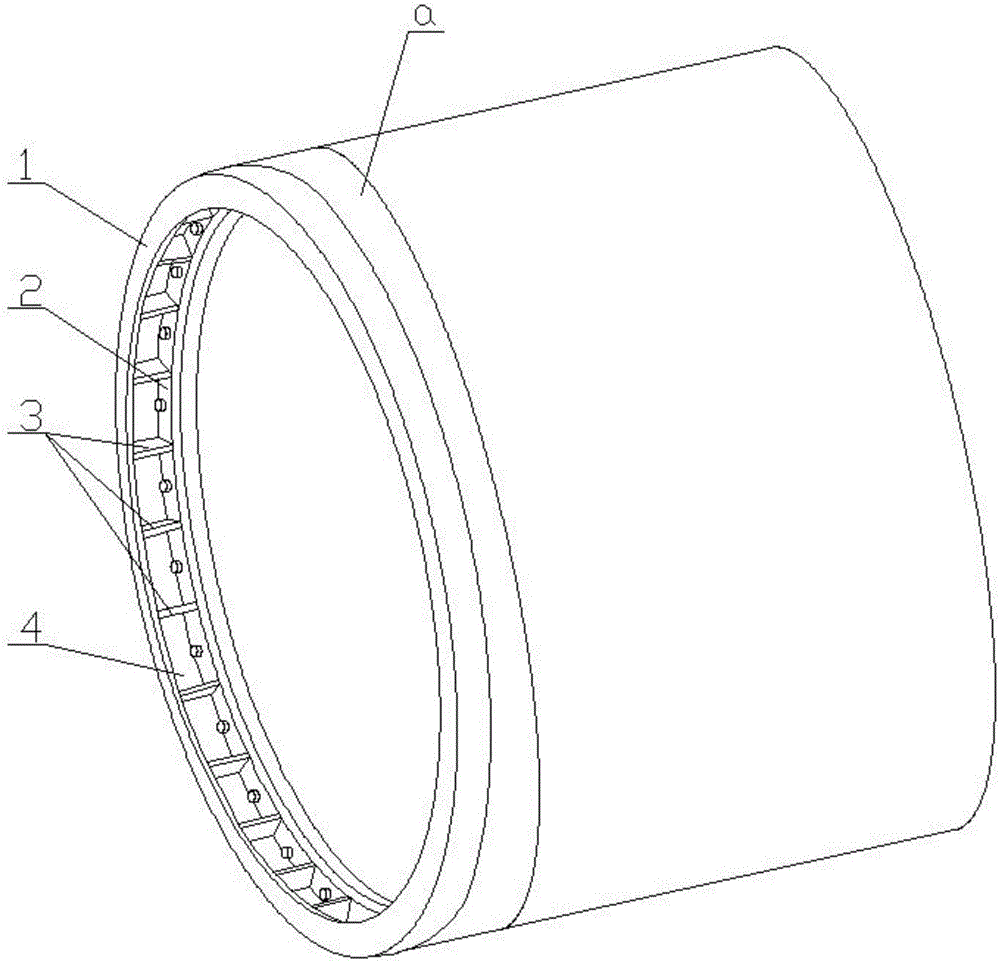

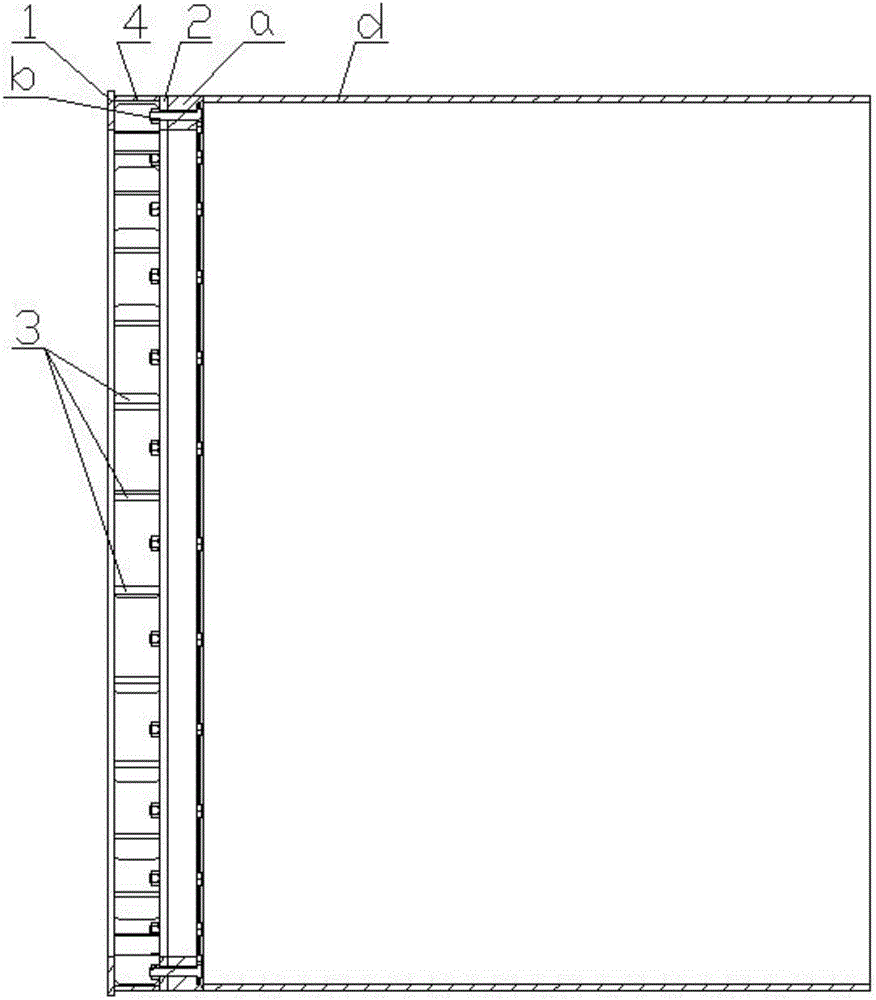

[0023] See Figure 1~4 , the present invention is a wind power generating set tower flange valgus anti-deformation shaping tool, which is fixedly connected to the tower flange a through several symmetrically fastened high-strength bolts b, and has a bottom plate 1 and a flat flange set opposite to each other. 2. Several ribs 3 and a support ring 4 are arranged by welding between the top surface of the bottom plate 1 and the bottom surface of the flat flange 2, each rib 3 is located inside the support ring 4, and each rib The backs of the plates 3 are tightly attached to the inner wall of the support ring 4 , and several rib plates 3 are evenly arranged between the top surface of the bottom plate 1 and the bottom surface of the flat flange 2 . The plate flange 2 is provided with several through holes corresponding to the positions of the mounting holes on the tower flange a. The anti-deformation plastic tooling adopts welding method, which has a simple structure, is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com