A low-temperature processing method of wheat flour and the system device and application thereof

A processing method and processing system technology, applied in the field of grain processing, can solve problems such as the unreachable moisture content of flour, the destruction of the nutritional content of grain flour, and the excessive content of magnetic metals, etc., achieving wide practicability, significant technical advantages, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: Wheat low temperature processing method

[0031] A kind of low-temperature processing method of wheat flour provided by the invention specifically adopts the following technical steps:

[0032] (1) Pretreatment: Store wheat in the underground granary at a temperature of 15°C-20°C and keep the granary dry.

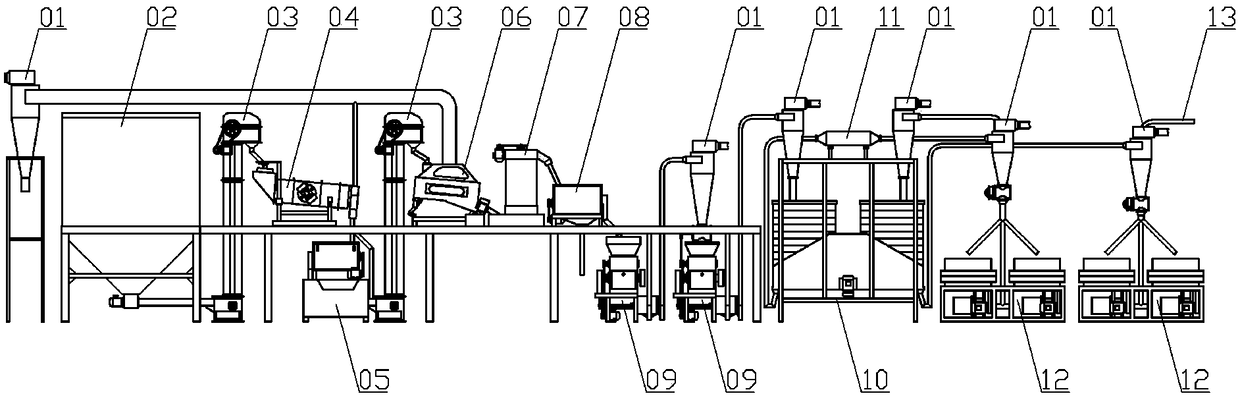

[0033] (2) Process wheat with the wheat processing system device: send the wheat from the underground granary into the feeding tank (02), pass through the self-balancing vibrating screen (04) for primary screening, and use the suction-type specific gravity to remove the roughness after the threshing machine (05) once. The stone machine (06) removes the stone, removes impurities with the cyclone dust collector (01), and then uses the wheat washing and stone removal machine (07) to moisten the wheat for 10h-12h at a temperature of 18°C-25°C. 12KGy gamma ray irradiation sterilization, through the horizontal threshing machine (08) secondary roughening, w...

Embodiment 2

[0035] Embodiment 2: wheat processing system device

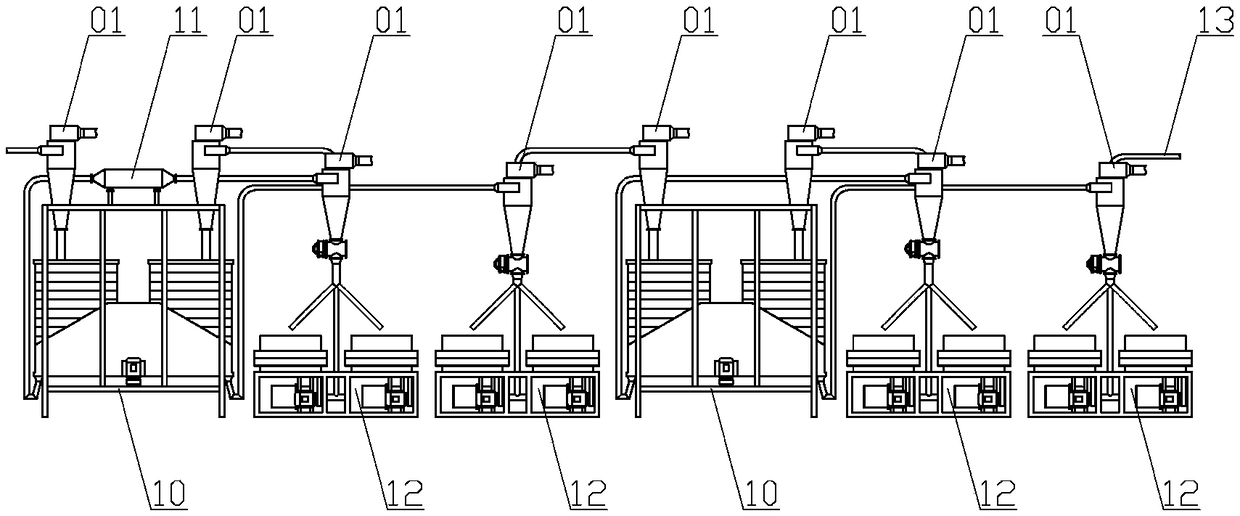

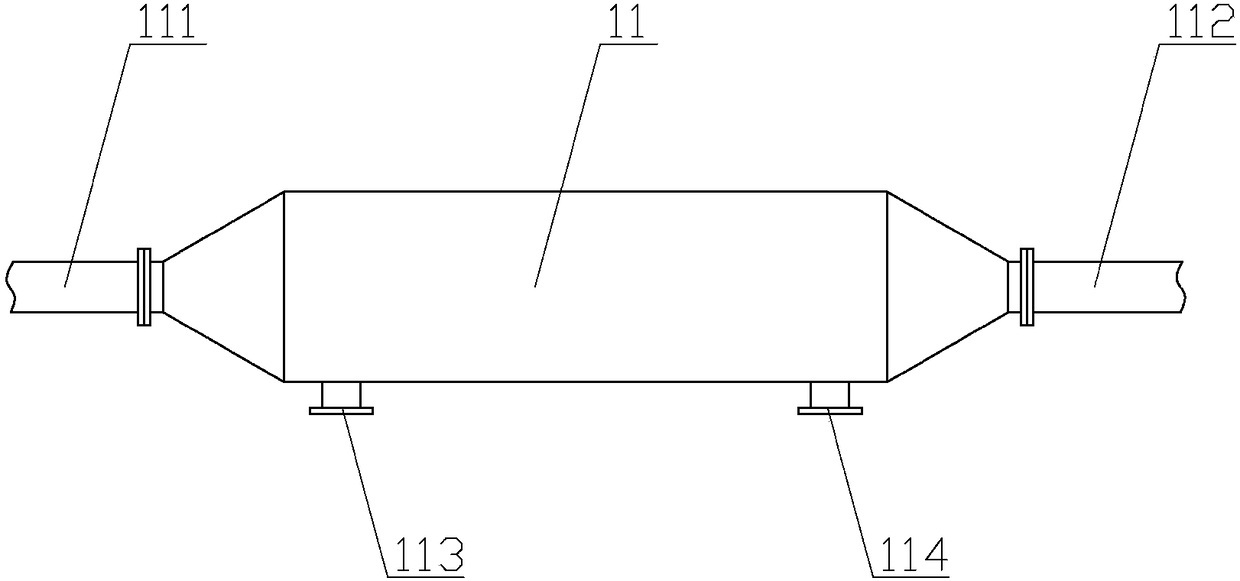

[0036] The wheat processing system device includes a feeding tank, a pretreatment mechanism, a crushing mechanism and a milling mechanism; a platform is set on one side of the feeding tank (02), and in the pretreatment mechanism, a self-balancing vibrating screen (04) above the platform and the feeding tank ( 02) The bottom is connected by an elevator (03), and the self-balancing vibrating screen (04) is connected with the wheat threshing machine (05) under the platform; the wheat threshing machine (05) is connected with the suction specific gravity destoner (06) on the platform Connected by the elevator (03), the suction specific gravity stone remover (06) is connected to the wheat washing and stone removing machine (07) and the horizontal wheat threshing machine (08); A cyclone dust collector (01) is installed between the pulverizers (09); in the pulverizing mechanism, the double-chamber flat screen (10) is connected to t...

Embodiment 3

[0041] Embodiment three: Wheat low-temperature processing method

[0042] On the premise of the first and second embodiments above, an optimized low-temperature processing method for wheat is further provided. Store wheat in the underground granary at a temperature of 15°C and keep the granary dry; use the wheat processing system device to process wheat: send the wheat in the underground granary into the feeding tank (02), pass through the self-balancing vibrating screen (04) for primary screening, and beat the wheat machine ( 05) After the first hair removal, use the suction specific gravity destoner (06) to remove stones, use the cyclone dust collector (01) to remove impurities, and then use the wheat washing and stone removal machine (07) to moisten the wheat for 10 hours at a temperature of 18°C At the same time, a dose of 6KGy γ-ray radiation was used to sterilize, and the horizontal threshing machine (08) was used for second hair removal, and the roller mill (09) was use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com