Test tube having filtering function

A technology of test tubes and functions, applied in the field of test tubes with filtering functions, can solve the problems of shortening the experimental process, long time consumption, difficulties, etc., and achieve the effect of filtering operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

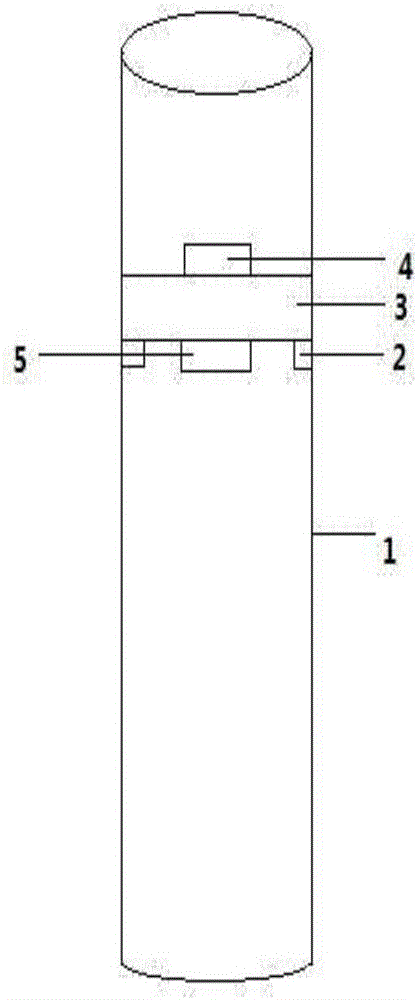

[0011] Such as figure 1 As shown, a test tube 1 with a filtering function includes a test tube 1, an inlay device 2, and a ceramic filter membrane 3. The inlay device and the test tube are integrated, and the ceramic filter membrane 3 is placed on the inlay device 2. The ceramic filter membrane faces the test tube The mouth end is the inlet 4, and the bottom end of the test tube is the outlet 5; when in use, according to the needs of the test, select the ceramic filter membrane 3 with different pore sizes, add the solution at the test tube mouth, the solution passes through the ceramic filter membrane inlet 4, and the filtered solution Flow out from the outlet 5 of the ceramic filter membrane to obtain the required solution. After the test is completed, the ceramic filter membrane can be taken out to be cleaned and dried for next use.

[0012] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com