Dust removal and environment protection system of automatic mud jacking device

A kind of equipment and environmental protection technology, which is applied in the separation method, transportation and packaging, and the separation of dispersed particles, etc., can solve the problems of serious dust, affecting the construction environment, and affecting the health of construction operators, so as to ensure health, avoid spillage, and improve construction operations environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

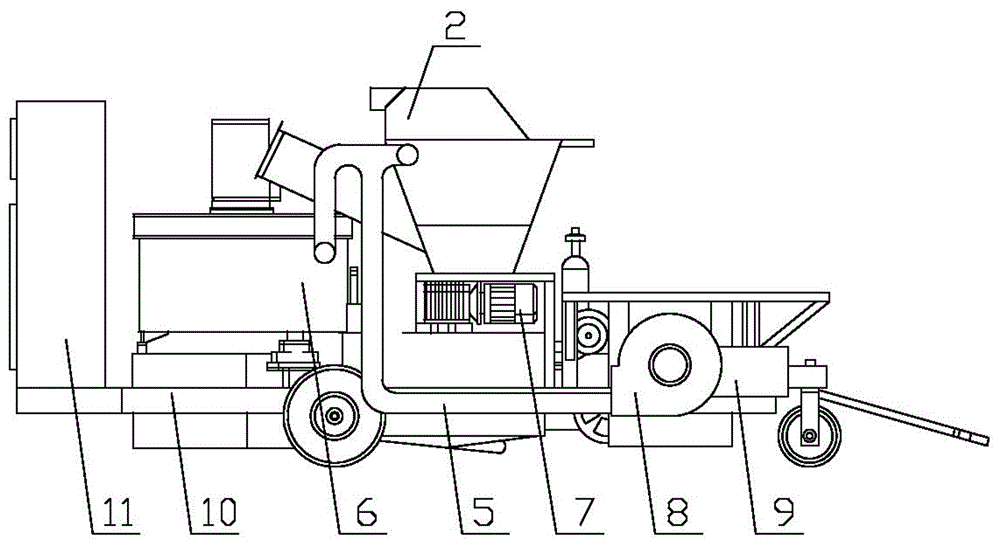

[0013] like figure 1 The dust removal and environmental protection system of an automatic grouting equipment shown includes a frame 10, a dust removal device arranged on the frame 10, and a PLC assembly electric control box 11 arranged at the front end of the frame 10. On the automatic grouting trolley A special dust removal device is set up. The dust removal device can absorb and reuse the dust generated by the grouting equipment during the working process, which effectively improves the construction work environment. Operators do not need to wear special dust masks, and can also protect construction operators. healthy.

[0014] The dust removal device includes a closed high-speed mixing tank 6 arranged on the vehicle frame 10, a closed automatic feeder 2 connected to the closed high-speed mixing tank 6, and a connecting pipe 5 connected to the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com