Quick molding-shaping shoe pad

An insole, orthopedic technology, applied in the field of orthopedic insole, can solve the problems of low efficiency, high cost, long production cycle and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

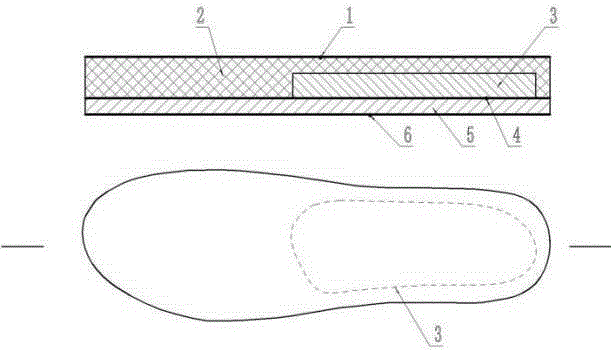

[0021] In the first step, the fabric is made of polyester knitted fabric, and the upper buffer layer is laminated with low-density EVA with a thickness of 2mm to obtain a composite fabric; the bottom material is made of black wear-resistant non-woven fabric and the lower buffer layer is made of high Density EVA is laminated to obtain a composite bottom material.

[0022] In the second step, according to the different sizes of the insoles planned to be produced, select the corresponding cutting dies, respectively punch and blank the composite fabric, composite base material, and TPU sheet with a thickness of 0.3mm, and process the insole fabric parts and base material in sequence parts, semi-rigid support sheet parts.

[0023] In the third step, according to the different sizes of insoles to be produced, an appropriate stamping die is selected to punch the TPU sheet with a thickness of 2.5mm into a moldable rigid support plate part.

[0024] The fourth step is to put the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com