A kind of feed curing kettle

A curing kettle and feed technology, applied in the field of feed curing equipment, can solve problems such as insufficient temperature, low starch gelatinization degree, poor pellet feed stability, etc., and achieve the effects of improving quality, increasing pellet production, and increasing feed remuneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

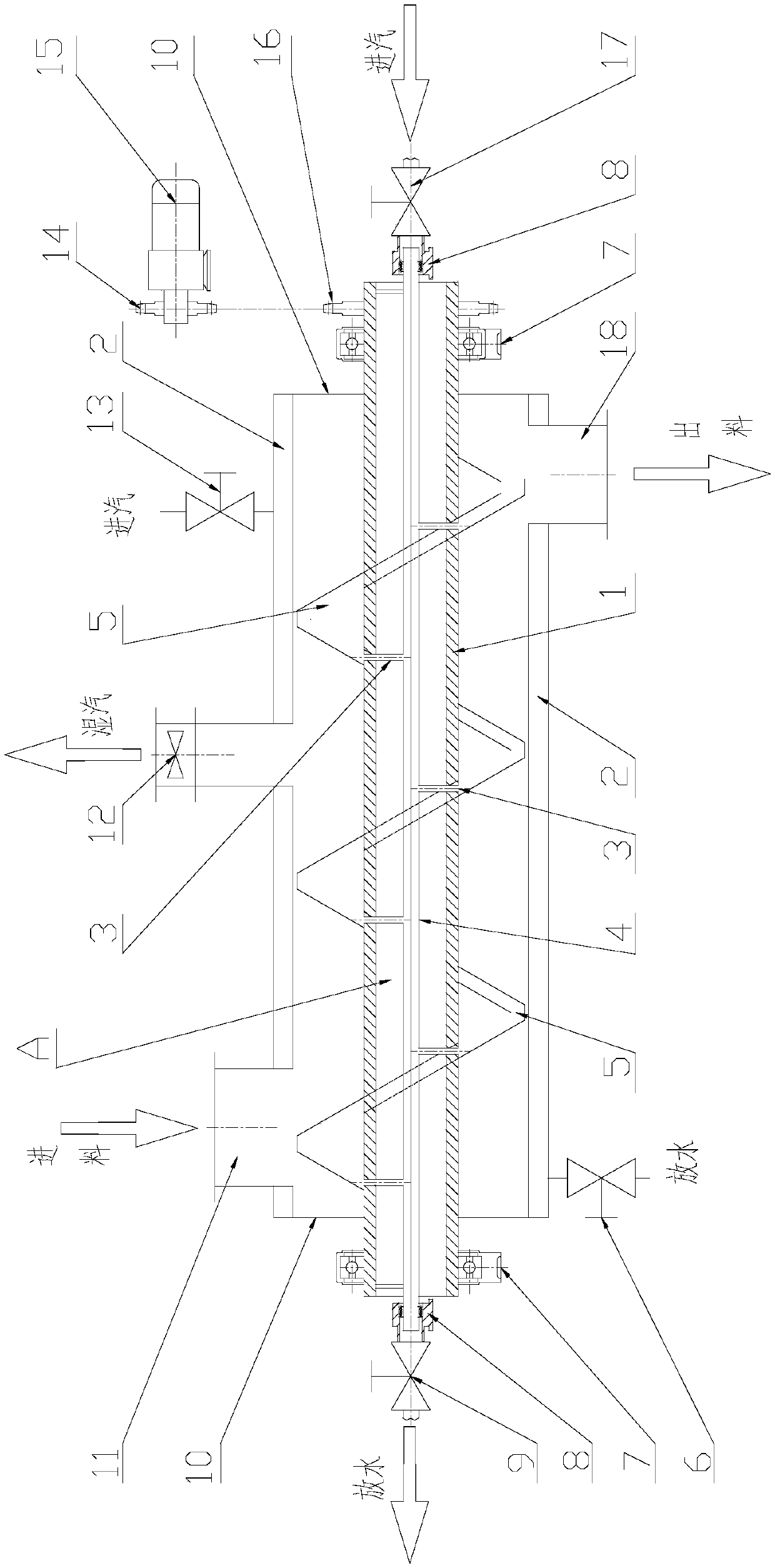

[0020] as attached figure 1 As shown, a feed curing kettle is composed of a hollow main shaft 1, a communication pipe 3, a central steam inlet pipe 4 and a double-layer spiral blade 5 to form a combined screw conveying shaft A, which is supported on a bearing seat 7, and the central steam inlet pipe 4 and The hollow main shaft 1 is fixedly connected, and its two ends are movably connected with the rotary joint 8. The centerlines of the rotary joint 8 and the central steam inlet pipe 4 coincide with the centerlines of the two bearing seats 7. The fixed jacket of the rotary joint 8 is respectively connected with the steam inlet valve 17 , Drain valve 9 is fixedly connected. The inner chamber of the central steam inlet pipe 4 communicates with the inner chamber of the airtight double-layer helical blade 5 through the communication pipe 3 without steam leakage.

[0021] On the periphery of the combined screw conveying shaft A, there is an annular sleeve 2. The annular sleeve 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com