A garlic on-demand mechanism

A garlic and on-demand device technology, applied in potato planters, planting methods, agriculture, etc., can solve the problems of high labor intensity, diverse planting modes, and inability to survive, and achieve the effects of reducing labor time, improving planting efficiency, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

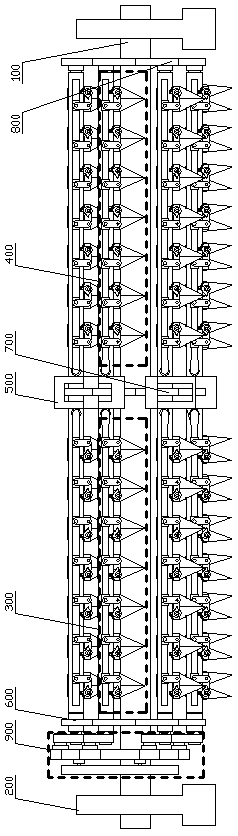

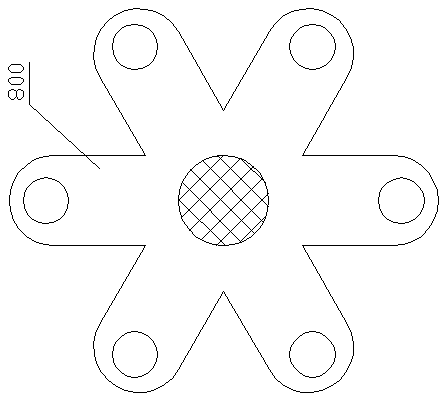

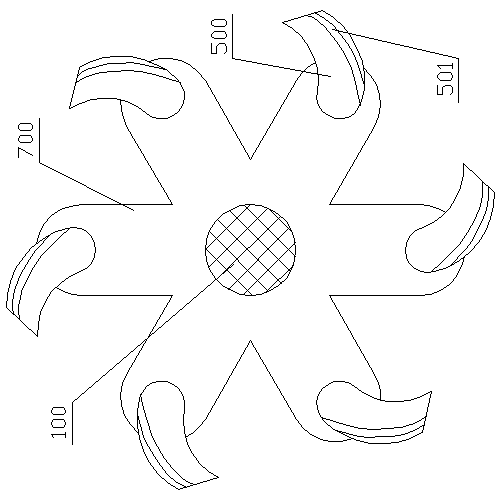

[0059] Attached below Figure 1-12 , a kind of garlic on-demand mechanism of the present invention is described in detail below.

[0060] as attached figure 1 Shown, a kind of garlic ordering mechanism of the present invention, its structure comprises left side orderer assembly 300, right side orderer assembly 400 and opening and closing structure 500 of the orderer.

[0061] The Garlic On Demand Agency also includes:

[0062] A main shaft 100, the main shaft 100 is arranged horizontally, the two ends of the main shaft 100 are installed on the frame of the garlic seeder through the bearing seat 200, one of the ends of the main shaft 100 is connected with the power device, and the power device works to drive the main shaft 100 to rotate;

[0063] Three mounting brackets, the three mounting brackets are respectively referred to as the first mounting bracket 600, the second mounting bracket 700, and the third mounting bracket 800, and the first mounting bracket 600, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com