Electromagnetic braking or coupling device having damping means for improved noise reduction

A clutch device, electromagnetic brake technology, applied in the direction of magnetic drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problem of electromagnetic brake or clutch device torque characteristics and negative effects of switching characteristics and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following drawings, unless otherwise specified, the reference numerals denote the same components with the same meaning.

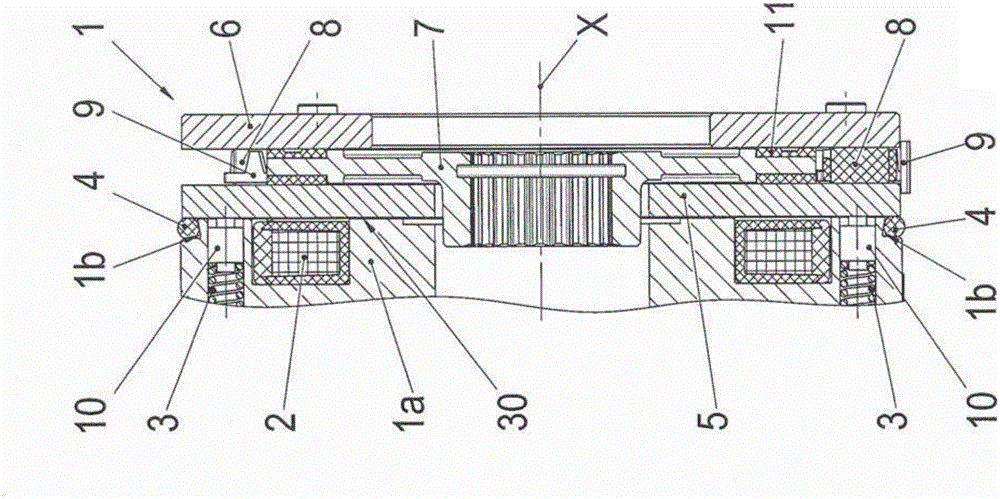

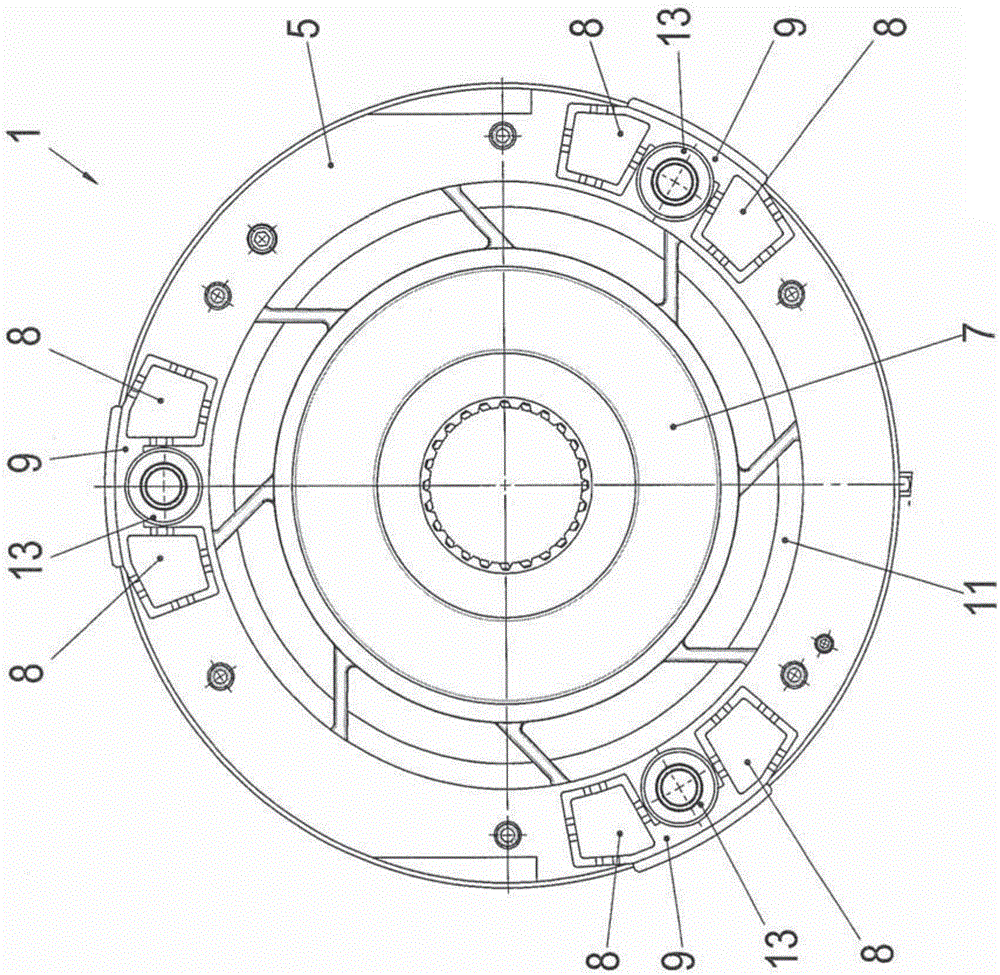

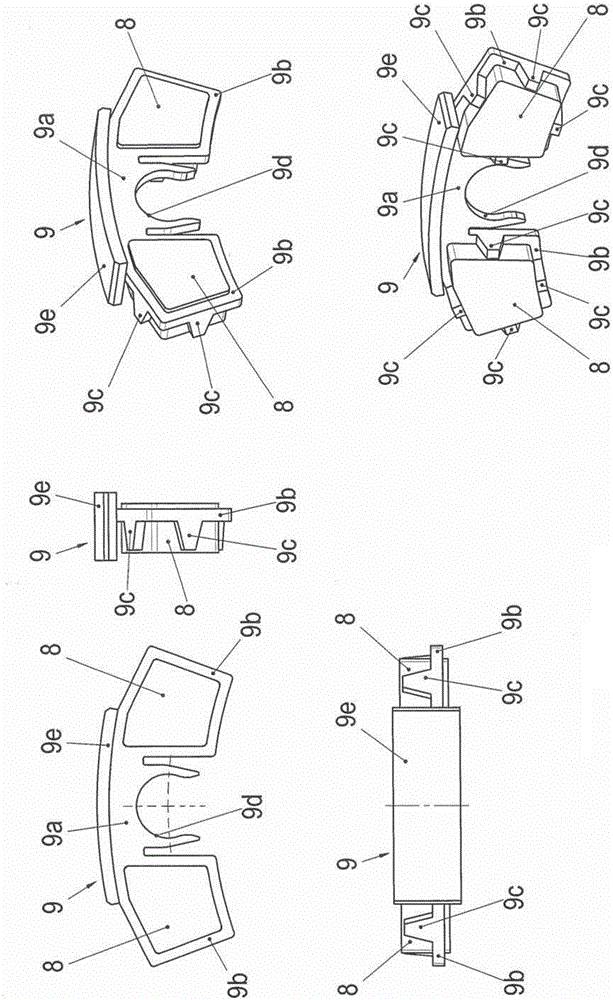

[0029] exist figure 1 shows a longitudinal section of a spring pressure brake, which is known per se, including a special damping element to be described in more detail. The spring pressure brake is designated with the reference numeral 1 and has a housing 1 a in which an exciter coil 2 is positioned in a conventional manner. The spring pressure brake 1 also has an armature disk 5 which is axially displaceable along the center axis X of the spring pressure brake 1 . At a predetermined distance to the right of the armature disk 5 there is a mounting surface 6 or a flange which can be part of a machine element or a wall element or the like on which the spring pressure brake 1 is mounted. Between the armature disk 5 and the mounting surface 6 is positioned in a known manner a friction disk 7, also called a brake or clutch disk, which is non-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com