High Productivity Manufacturing of Soft Machines

A soft and robotic technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems such as manufacturing process interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

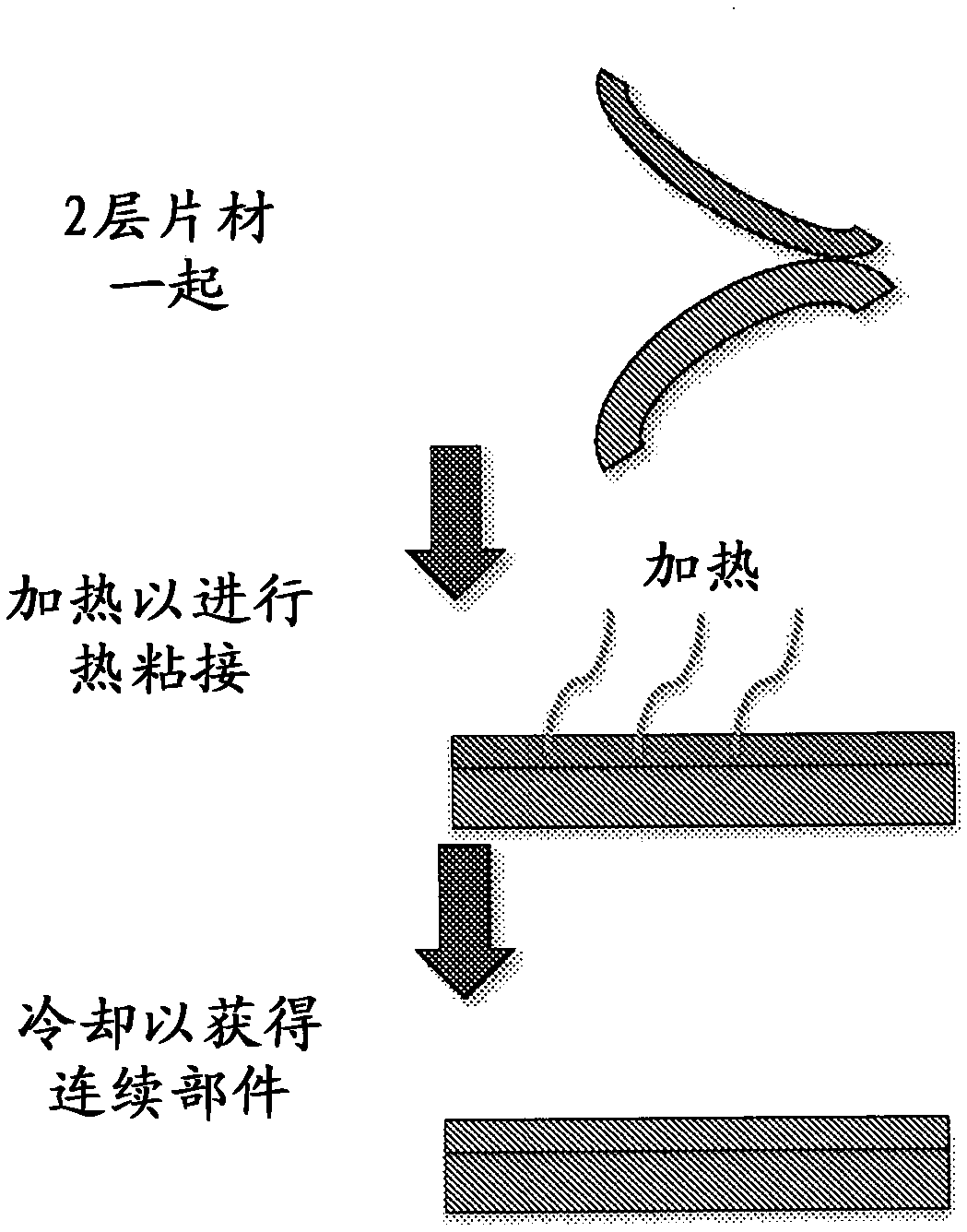

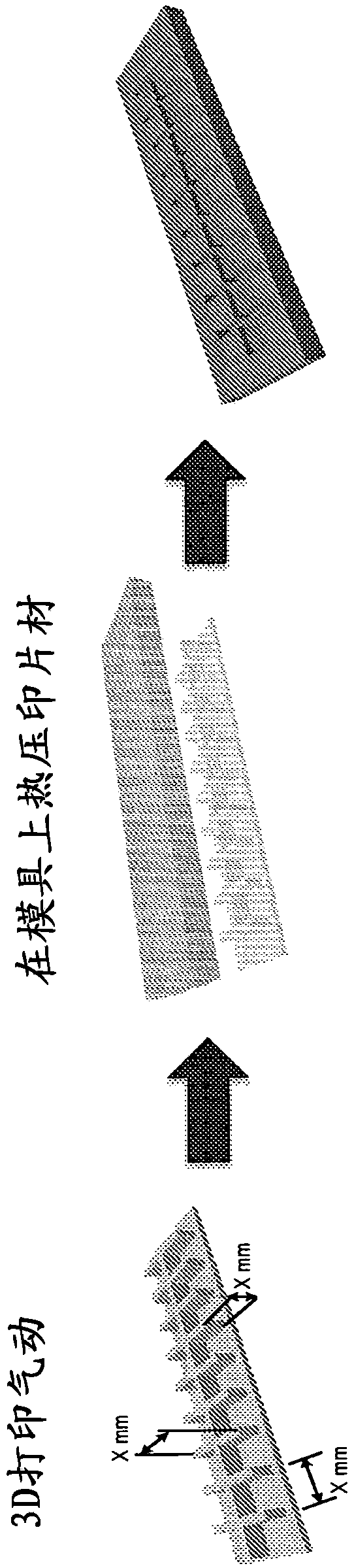

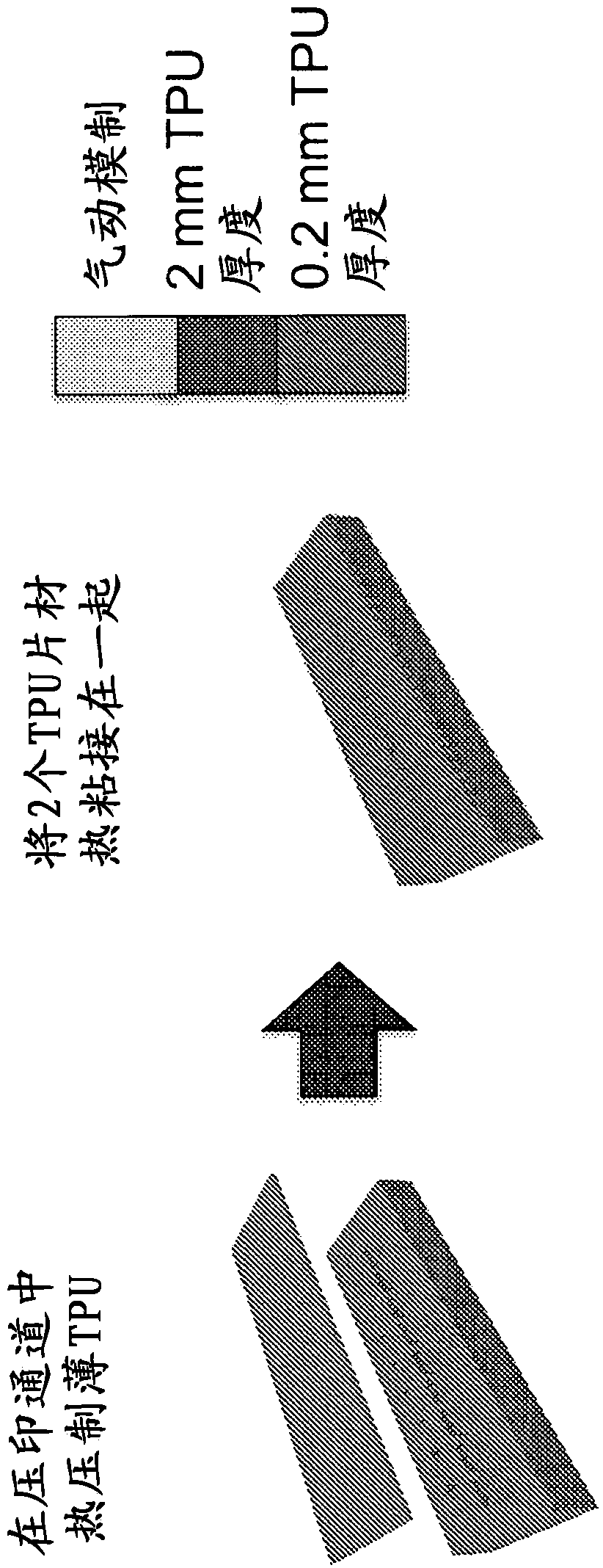

[0042] A scale-up procedure for fabricating soft machines from thermoplastic materials is described. The machine includes an elastic expandable (extensible) first layer and a harder, non-extensible second layer thermally bonded to the first layer. The layers may be bonded directly to each other, or they may be bonded through one or more intervening layers. The machine also includes a pneumatic network that is pressurized to actuate the machine. The pneumatic network can be located in the extensible layer or in the non-extensible layer, or in an intermediate third layer between these two layers. The stiffer, non-extensible layer may optionally include a reinforcement layer, such as paper or mesh.

[0043] In one or more embodiments, a soft robotic machine may be fabricated by thermally bonding layers of thermoplastic material. Thermoplastic materials become flexible or moldable above a certain temperature and solidify when cooled. At least one layer is a thermoplastic elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com