Novel pore plate of air-blowing type instant freezer

A quick-freezing machine and orifice plate technology, applied in lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., to achieve the effect of improving heat transfer coefficient, improving single-directional impact problem, and increasing freezing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the operation process and creative features realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

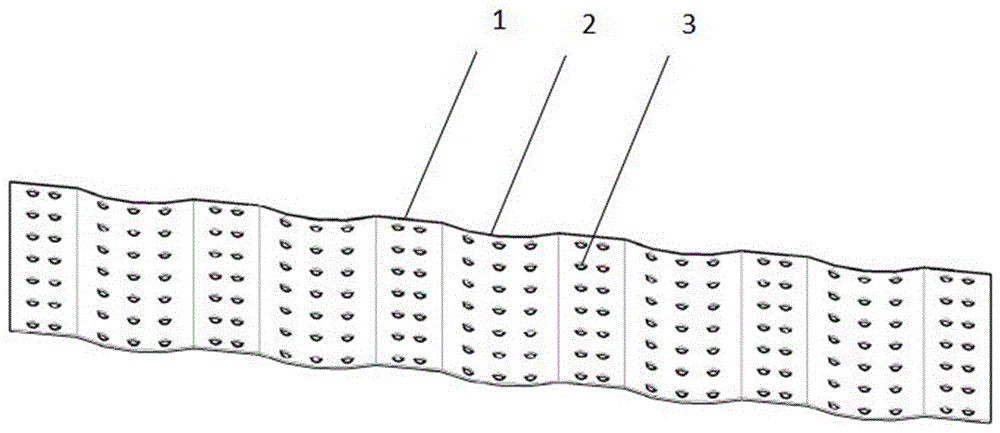

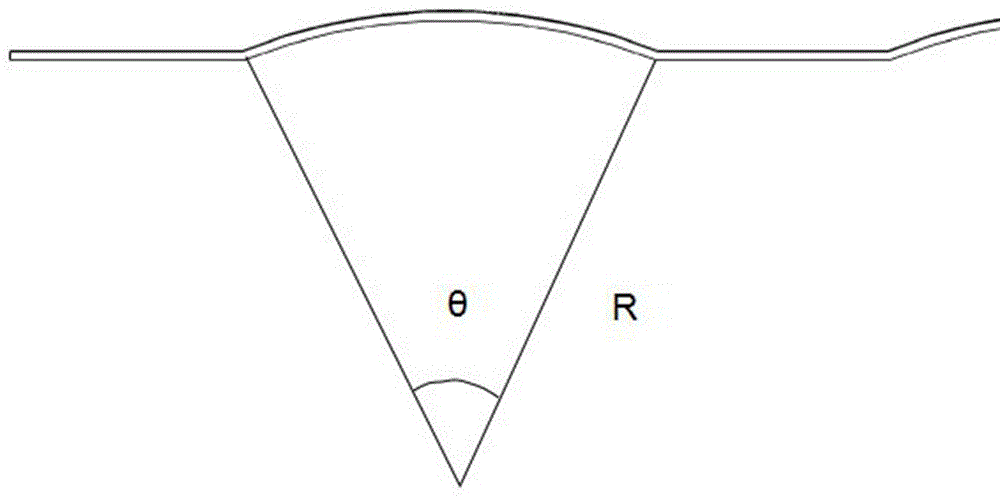

[0018] The orifice plate of the blast type quick-freezing machine includes a positive blowing orifice plate surface 1, an orifice arc surface 2, and an orifice opening 3; the orifice plate structure of the new blasting type quick-freezing machine is characterized in that the width of the positive blowing orifice plate surface 1 is 80mm , the orifice plate surface of length A; the arc surface 2 of the orifice plate is a circular arc surface with a radius R and the included angle of the arc surface is 45°; The radius of the orifice hole 3 is 5mm, and the hole spacing along the direction of the groove is 40mm; the orifice arc surface 2 is distributed with three rows of orifice holes 3, and the angle between two adjacent rows of orifice holes 3 is 11.25° , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com