Air conditioner and its panel bracket and front housing assembly

A panel and component technology, applied in air conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as reducing user experience and large body noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

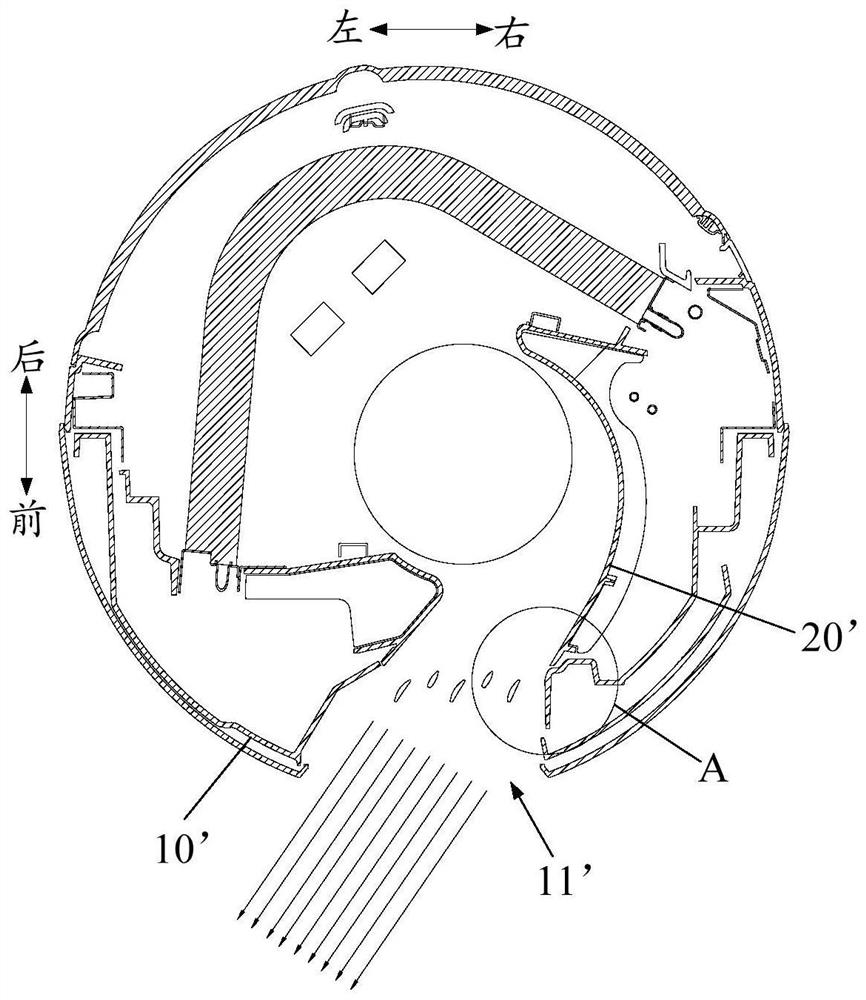

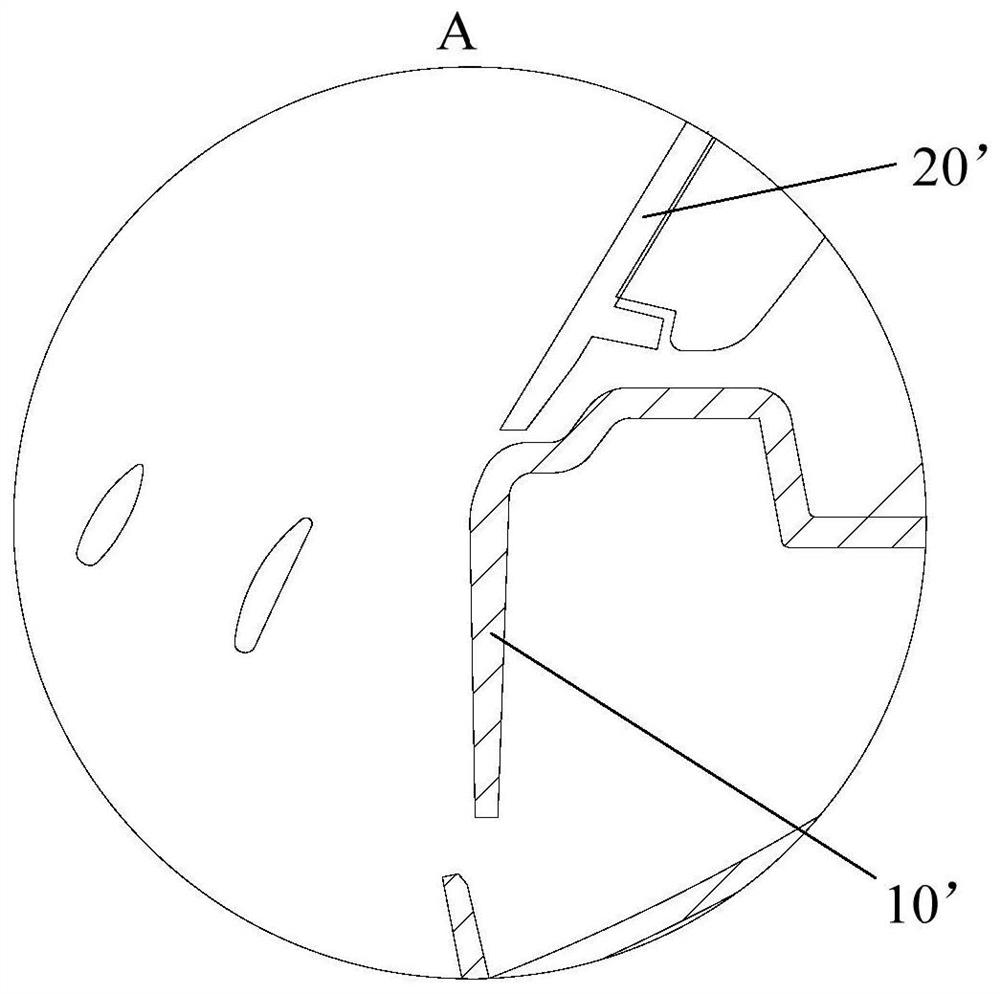

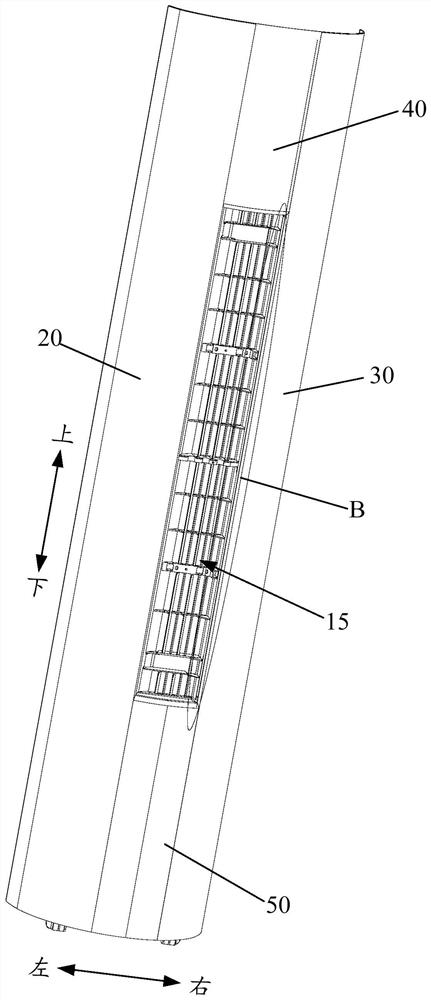

[0094] Such as Figure 3 to Figure 8 As shown, the air conditioner is a circular cabinet machine, the air outlet 15 is located directly in front of the panel bracket 10, and the air supply port of the air duct is located at a position to the right behind the air outlet 15, and the air supply direction of the air supply port is biased to the left side of the machine; Then, among the two oppositely arranged vertical slats on the panel support 10, the first slat 11 is located on the left side, and the first slat 11 opens obliquely to the left to ensure that the air outlet channel and the air duct system The second strip 12 is located on the right side, and the second strip 12 basically extends towards the front, so that the final air outlet 15 is located directly in front of the panel bracket 10, so as to ensure The aesthetics of the product appearance; at this time, it is only necessary to set the guide surface 131 on the second slat 12 on the right side, specifically at the end...

Embodiment 2

[0095] Embodiment 2 (not shown in the figure)

[0096] The difference with Embodiment 1 is that: the air supply port is located at the left position behind the air outlet 15, so that the air supply direction of the air supply port is biased to the right side of the machine; The one on the right is the first strip 11, and the first strip 11 is inclined to the right to ensure that the air outlet channel is compatible with the air duct system, while the one on the left is the second strip 12, and the first strip 11 is inclined to the right. The two strips 12 basically extend toward the front, so that the final air outlet 15 can be positioned directly in front of the panel support 10, so as to ensure the appearance of the product; The guide surface 131 can be provided on the two slats 12 , specifically at the end of the second slat 12 close to the air outlet.

[0097] After testing, the noise and air volume comparison test data of the original panel bracket and the improved panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com