Noise-reducing range hood

A technology for range hoods and noise reduction, applied in the field of range hoods, to achieve the effects of easy cleaning of the volute, reduction of noise, and elimination of flow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

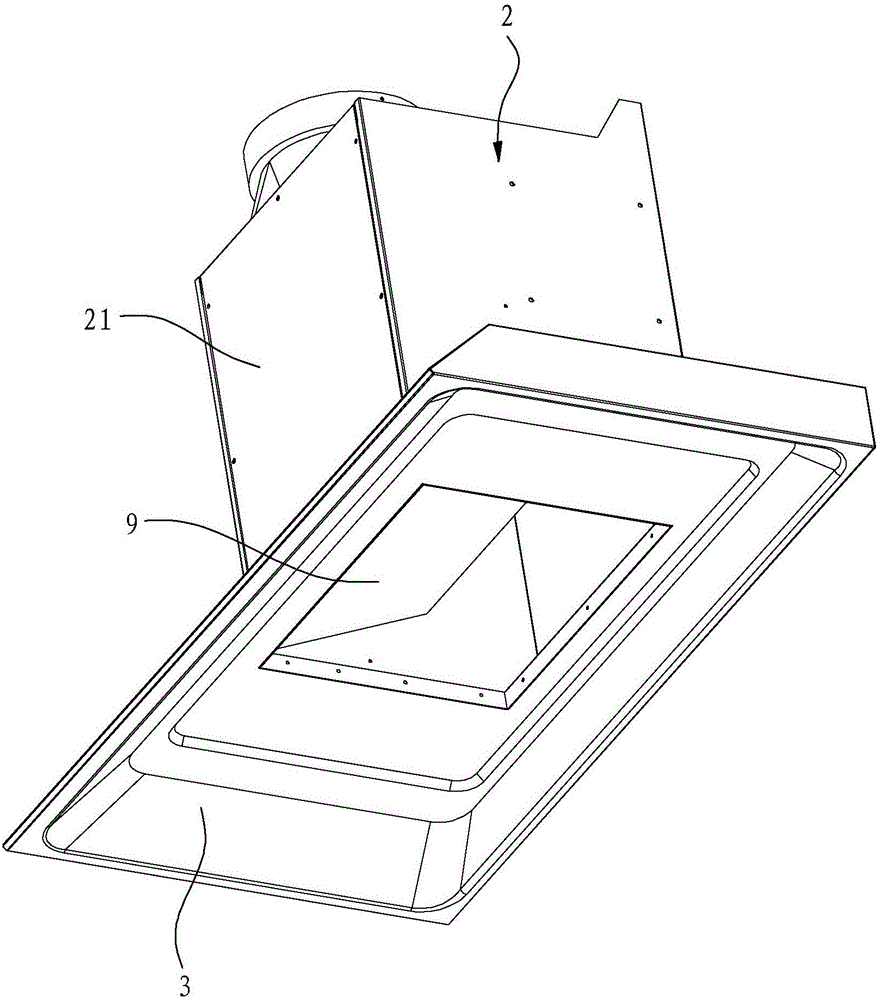

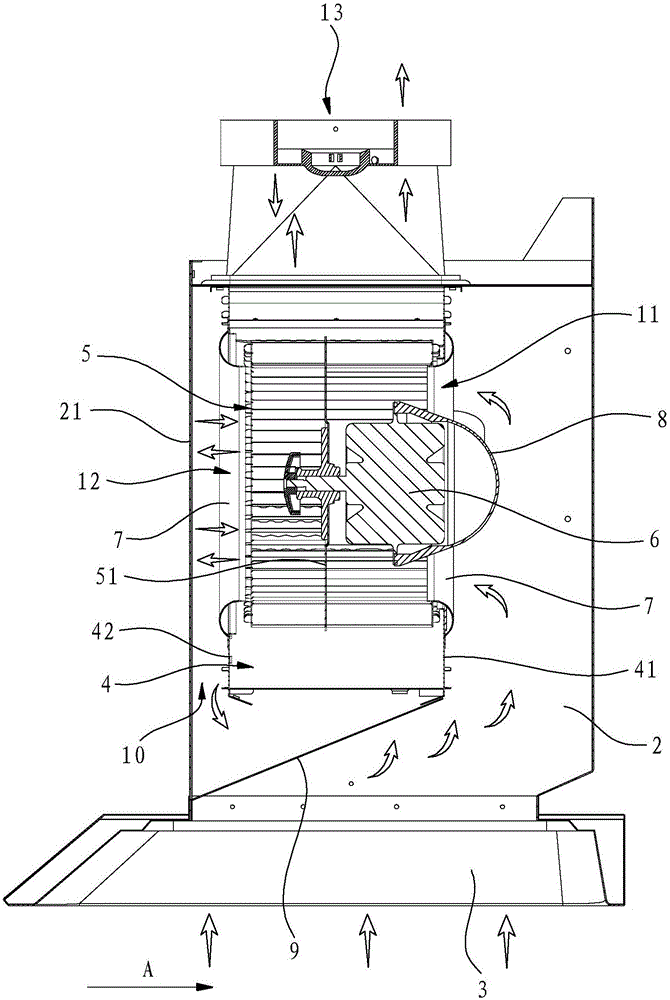

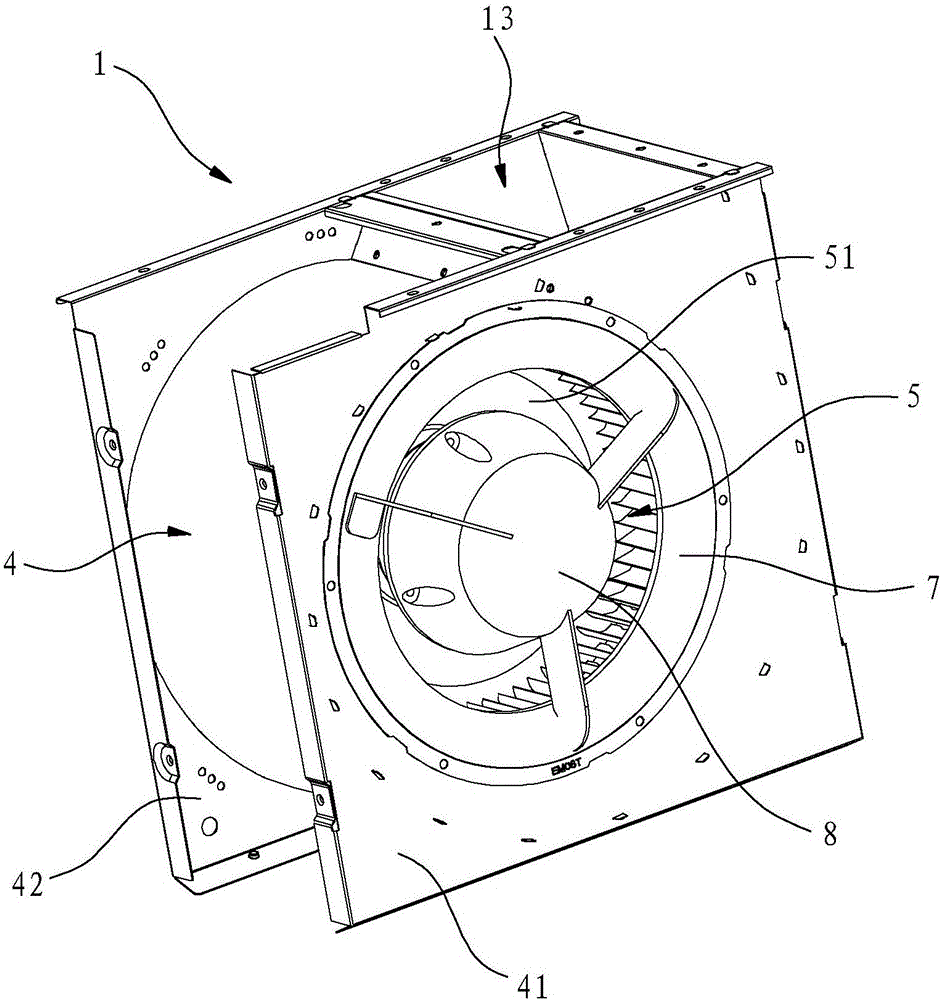

[0031] like Figure 1 to Figure 3 As shown, the noise reduction range hood in this embodiment includes a fan 1, a fan cover 2 and a smoke collection hood 3, and the fan 1 includes a volute 4, an impeller 5 and a motor 6 for driving the impeller, wherein the volute has a rear volute Side plate 41 and volute front side plate 42. The fan 1 is arranged in the fan outer cover 2 , and the smoke collecting cover 3 is arranged under the fan outer cover 2 . by figure 2 The direction indicated by the middle arrow A is backward, and the rear air inlet 11 is provided on the rear side plate 41 of the volute, and the front air inlet 12 is provided on the front side plate 42 of the volute, and the rear air inlet 11 and the front air outlet 12 pass through the impeller 5 The middle plate 51 is mutually isolated, and the rear air inlet 11 and the front air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com