Offshore power generation device and method

A power generation device and servo motor technology, applied in ocean energy power generation, hydropower generation, engine components, etc., can solve the problems of high price and low energy conversion efficiency, and achieve wide application range, high energy conversion efficiency and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

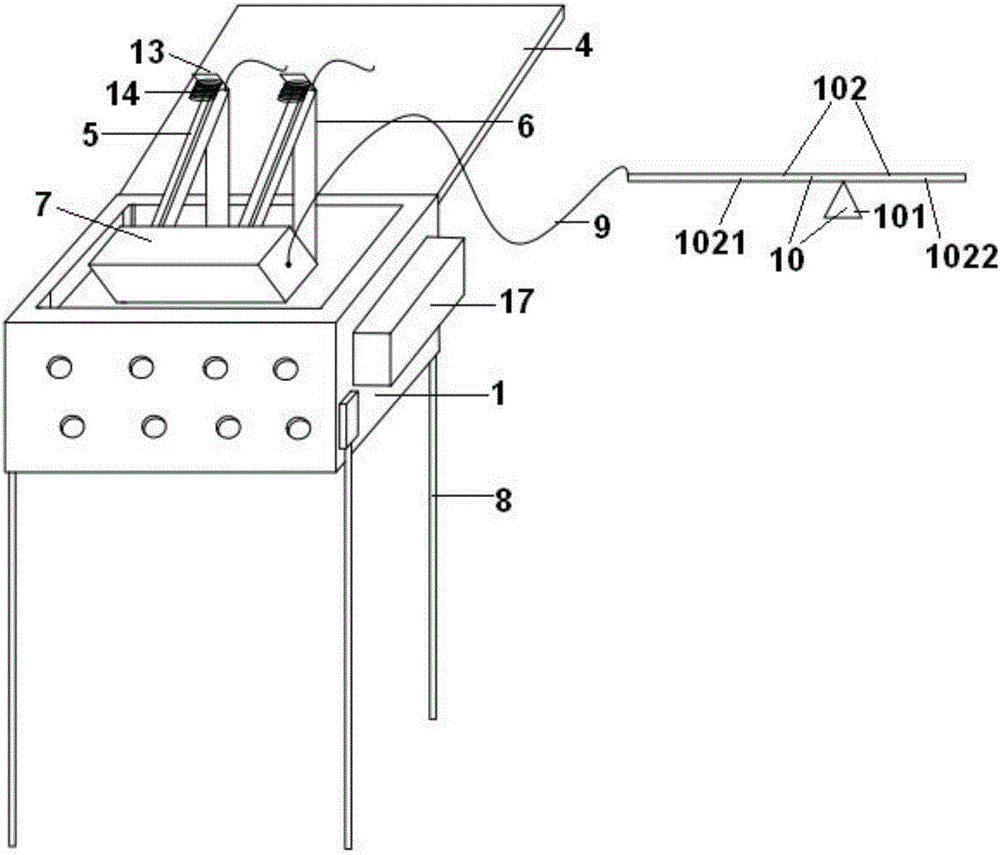

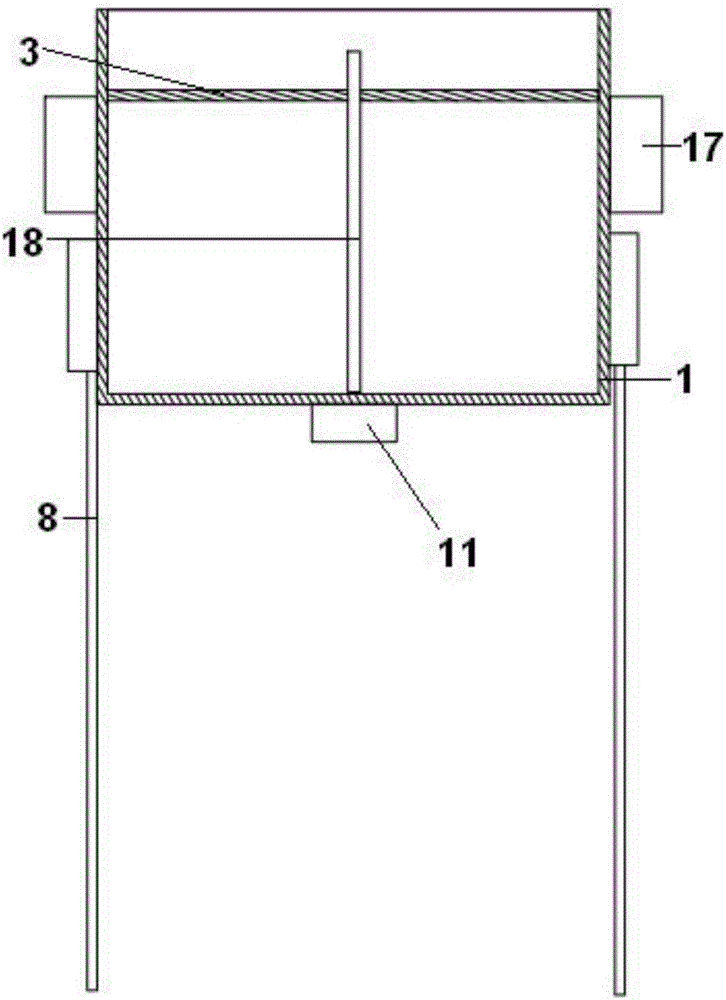

[0057] Such as figure 1 , figure 2 , Figure 7 The embodiment shown is a kind of offshore power generation device, comprising a suspension box 1 with an upper opening on the water, a controller 2 on the suspension box, an annular buoy on the edge of the suspension box, a power generation device, and a floating The flat plate 3 in the box, the two inclined guide rails 5 arranged on the flat plate, the two support columns 6 for respectively supporting the upper ends of the two guide rails, the hollow swing body 7 arranged on the two guide rails, and the suspension box 4 cables 8 on the top, a stay rope 9 on the swing body and a lever 10 above the suspension box; one end of the lever is connected to the stay rope, and the other end of the lever is connected to the power generation device through a connecting rope; the lower end of each cable is equipped with anchor;

[0058] The inner wall of the suspension box is provided with 4 guiding vertical grooves, and the flat plate i...

Embodiment 2

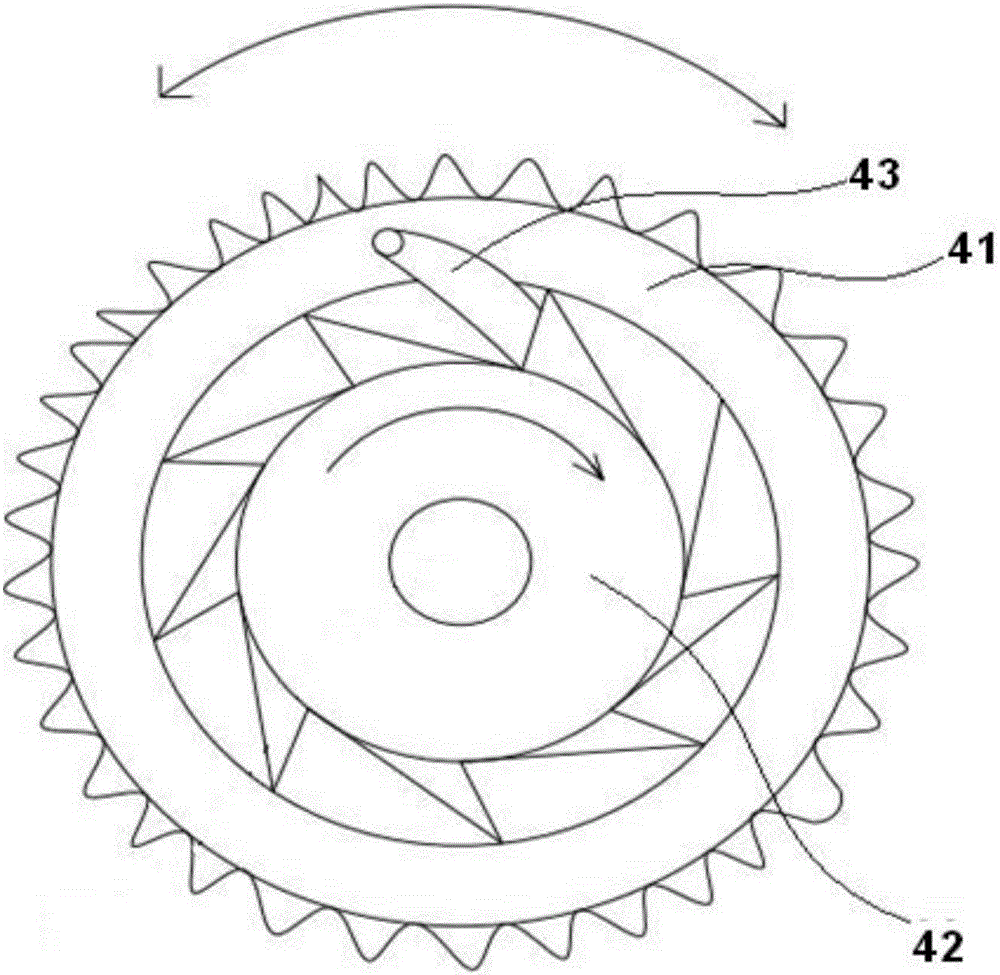

[0075] Embodiment 2 includes all structures and step parts of Embodiment 1, such as Figure 4 , Figure 5 , Figure 7 As shown, each cable in Embodiment 2 includes an elastic tube with a closed lower end, and a plurality of metal sleeves 81 that are sequentially inserted on the elastic tube; the upper end of the elastic tube of each cable is connected to the outlet pipe of the air pump 82 , each elastic tube is provided with an air pressure sensor 86, and each air pressure sensor and air pump are electrically connected to the controller.

[0076] The metal sleeve includes a tapered insertion section 83 located at the lower part of the metal sleeve, an upwardly flared horn section 84 positioned at the upper part of the metal sleeve for matching with the insertion section of the adjacent metal sleeve, and a horn section 84 located between the insertion section and the horn. Connect segment 85 between segments.

[0077] The step 100 of embodiment 1 also includes a control step...

Embodiment 3

[0083] Embodiment 3 includes all structures and steps of Embodiment 1, and the suspension box of Embodiment 3 is also provided with such figure 2 , Figure 7 The water inlet pump 15, the drainage pump 16 and two symmetrically arranged ballast tanks 17 are shown. The water inlet pump and the drainage pump are connected to the two ballast tanks through water pipes, and both the water inlet pump and the drainage pump are electrically connected to the controller;

[0084] (8-1) When B≥2.5W, the controller controls the servo motor to drive the screw to rotate, so that the support column enters the suspension box;

[0085] And the controller controls the water inlet pump to pump water into the two ballast tanks. After the water inlet pump pumping time reaches T1=2 minutes, the controller controls the water inlet pump to stop working;

[0086] (8-2) When B<2.5W, the controller controls the drainage pump to pump water out of the two ballast tanks. After the drainage time of the drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com