Aluminum template connection piece

A technology of connectors and aluminum formwork, which is applied to the connection parts of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of falling off connecting sleeves, inconvenient use, and waste of available area. , to achieve the effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

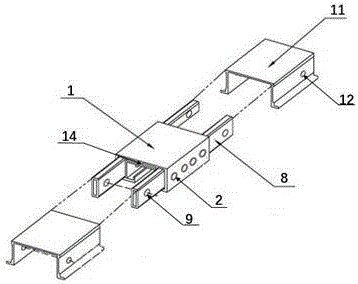

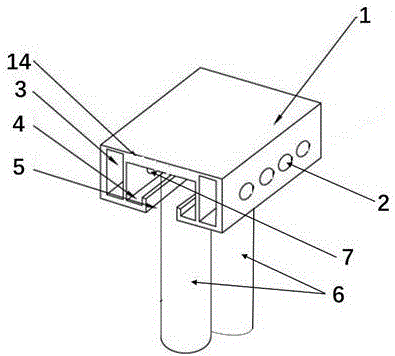

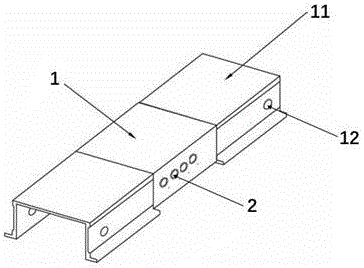

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] An aluminum formwork connector, comprising a connecting plate 1, the connecting plate 1 is a left-right symmetrical square groove structure, four connecting bolt holes 2 are arranged on the side wall of the connecting plate 1, and left and right Two sets of symmetrical casing holes 3 and two sets of notches 4 symmetrically left and right, two sets of notches 4 are symmetrically arranged to form a column groove 5, and two columns 6 are vertically inserted inside the column groove 5, and two columns are arranged on the top of the column groove 5. 6 top matching grooves, the column 6 vertically passes through the column groove 5 and is inserted into the groove.

[0024] In order to realize the fixed connection between the connecting plate 1 and the internal structural components of the tube hole 3 , four extended connection bolt holes 7 corresponding to the connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com