Uranium, iron, thorium and rare earth extraction and separation process

A rare earth extraction, separation and process technology, which is applied in the field of uranium, iron, thorium and rare earth extraction and separation processes, can solve the problems of difficult separation from uranium and inability to meet commodity requirements, achieve comprehensive utilization, avoid ammonia nitrogen wastewater problems, reduce The effect of extraction separation stages and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

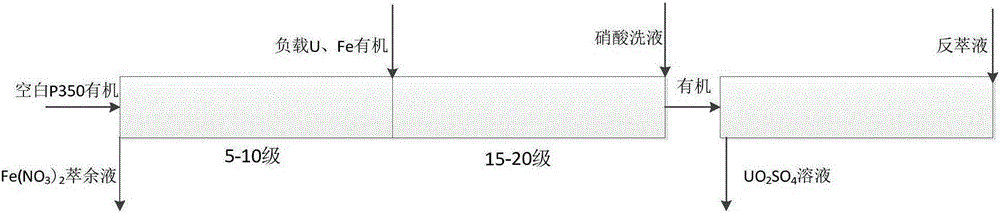

[0033] Use 30% P in the hydrochloric acid system 350 ‐ Kerosene extraction system for UFe / ThRE separation, control the concentration of [RE+Th+U+Fe+Ti] in the feed liquid to 180g / L, [TiO 2 ]=3.5g / L, [H + ] = 2.0 mol / L, using countercurrent extraction, compared to organic phase: aqueous phase = 4: 1, the number of extraction stages is 15, and the organic phase loaded with U and Fe and the raffinate containing Th and RE are obtained. Using 2.0 mol / L HCl to countercurrent wash the organic phase loaded with U and Fe, the comparison is organic phase:water phase=6:1, and the number of stages is 18.

[0034] The organic phase is fed with loaded U and Fe, and the washing section uses 0.3mol / L HNO 3 (which contains 3wt.%H 2 o 2 ) solution to wash the loaded U and Fe organic phases, the extraction section uses a blank P350 organic phase feed, and separates U / Fe by fractional extraction to obtain an organic phase loaded with pure U and Fe(NO 3 ) 2 raffinate. Compared with blank or...

Embodiment 2

[0041] Use 35% P in the hydrochloric acid system 350 ‐ Kerosene extraction system for UFe / ThRE separation, control the concentration of [RE+Th+U+Fe+Ti] in the feed liquid to 250g / L, [TiO 2 ]=1g / L, [H + ]=2.5mol / L, using counter-current extraction, compared to organic phase:water phase=3:1, the number of extraction stages is 18, and the organic phase loaded with U and Fe and the raffinate containing Th and RE are obtained. 2.5 mol / L HCl is used for countercurrent washing of the organic phase loaded with U and Fe, compared to organic phase:water phase=6:1, and the number of stages is 18.

[0042] The organic phase is fed with loaded U and Fe, and the washing section uses 0.5mol / L HNO 3 (which contains 5wt.% Na 2 SO 3 ) solution to wash the loaded U and Fe organic phases, the extraction section uses a blank P350 organic phase feed, and separates U / Fe by fractional extraction to obtain an organic phase loaded with pure U and Fe(NO 3 ) 2 raffinate. Compared with blank organi...

Embodiment 3

[0045] Use 25% P in the hydrochloric acid system 350 ‐ Kerosene extraction system for UFe / ThRE separation, control the concentration of [RE+Th+U+Fe+Ti] in the feed liquid to 200g / L, [TiO 2 ]=2g / L, [H + ]=2.3mol / L, using counter-current extraction, compared to organic phase:water phase=4:1, extraction stage is 20, to obtain organic phase loaded with U and Fe and raffinate containing Th and RE. Use 2.2mol / L HCl to carry out the countercurrent washing of the organic phase loaded with U and Fe, and the comparison is organic phase:water phase=8:1, and the number of stages is 20.

[0046] The organic phase is fed with loaded U and Fe, and the washing section uses 0.5mol / L HNO 3 (Containing 1wt.% ascorbic acid) solution washes the loaded U and Fe organic phases, the extraction section uses a blank P350 organic phase feed, and U / Fe is separated by fractional extraction to obtain the organic phase loaded with pure U and Fe (NO 3 ) 2 raffinate. Compared with blank organic phase: l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com