A kind of hydrogel for regulating three-dimensional micropatterned growth of cells and its preparation method

A micropatterning and hydrogel technology, which is applied in the field of biomedical materials and tissue engineering, can solve the problems of few surface treatment methods and limit the application of micropatterning technology in tissue engineering, and achieve a simple and easy preparation method, which is well adjustable Degradability, the effect of easy control of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

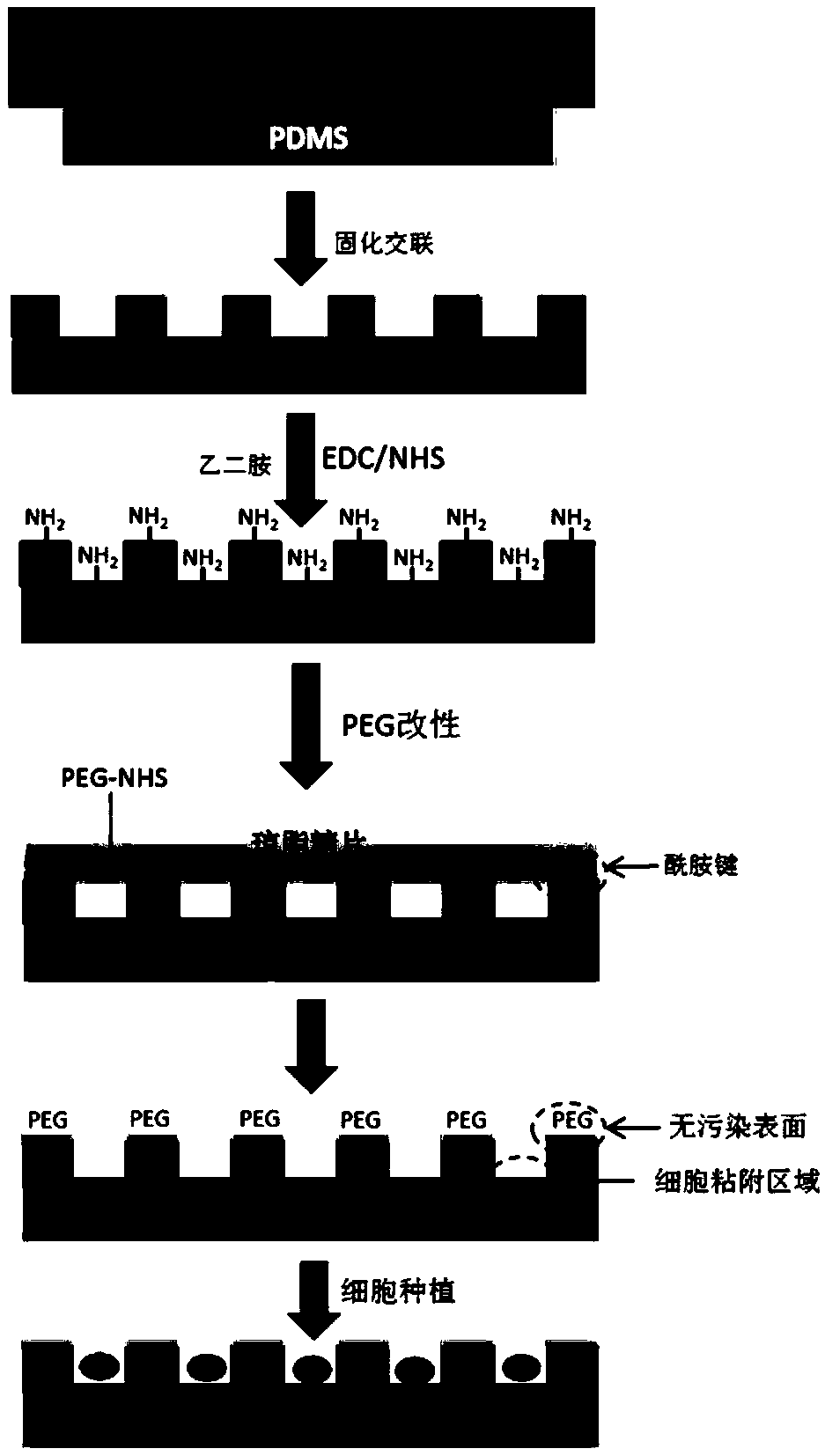

[0037] A three-dimensional micropatterned calcium alginate hydrogel that regulates the growth of cells in straight stripes is prepared by the following method:

[0038] (1) Use the designed mask plate to prepare a striped groove first-level photoresist micropattern template with a groove width of 50 μm, a spacing of 50 μm, and a depth of 50 μm by micropattern negative lithography, and pour PDMS glue on its surface Polymer, after cross-linking and curing in an oven at 60°C for 12 hours, peel off the film to obtain a secondary PDMS glue micro-pattern template, and place the micro-pattern upward in a petri dish with a diameter of 3 cm;

[0039] (2) Prepare 20 mL of sodium alginate aqueous solution with a concentration of 10 mg / ml, add 0.06 g of calcium phosphate powder, stir for 10 min until uniformly dispersed, and obtain a mixed system of sodium alginate and calcium phosphate powder;

[0040] (3) Take 5 mL of the mixed system obtained in step (2) and pour it on the PDMS glue mi...

Embodiment 2

[0046] A three-dimensional micropatterned polyacrylamide hydrogel that regulates the growth of cell square arrays is prepared by the following method:

[0047] (1) Use the designed mask plate to prepare a first-level photoresist micropattern template with a square array of grooves with a side length of 100 μm, a spacing of 50 μm, and a depth of 100 μm by micropattern negative lithography, and pour PDMS glue on its surface Prepolymer, cross-linked and cured in an oven at 60°C for 12 hours, peeled off to obtain a secondary PDMS glue micropattern template, and placed the micropattern upward in a petri dish with a diameter of 3 cm;

[0048] (2) Mix 4mL of 50wt% acrylamide solution, 4.8mL of 0.5wt% methylenebisacrylamide solution, 1μL of tetramethylethylenediamine (TEMED) catalyst and 10% 0.1mL of ammonium persulfate (AP) solution Finally, take 5 mL and pour it on the PDMS glue micro-pattern template obtained in step (1). After the polyacrylamide hydrogel is solidified and cross-li...

Embodiment 3

[0054] A three-dimensional micropatterned gelatin hydrogel that regulates the growth of cell network stripe grooves is prepared by the following method:

[0055] (1) Use the designed mask plate to prepare a first-level photoresist micropattern template with mesh stripe grooves with a side length of 50 μm, a spacing of 100 μm, and a depth of 100 μm by micropattern negative photolithography, and pour PDMS glue on its surface Prepolymer, cross-linked and cured in an oven at 60°C for 12 hours, peeled off to obtain a secondary PDMS glue micropattern template, and placed the micropattern upward in a petri dish with a diameter of 3 cm;

[0056] (2) Disperse 5wt% gelatin evenly, take 5mL and pour it on the PDMS glue micro-pattern template obtained in step (1), place the small petri dish loaded with gelatin and PDMS glue at 4°C for 2 hours and solidify , add 5wt% glutaraldehyde for cross-linking for 1 hour, take it out, remove the PDMS glue and soak it in water several times to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com