A process automatic control method for sludge composting rapid aerobic fermentation process equipment

A technology of aerobic fermentation and process equipment, applied in the direction of electrical program control, sewage/sludge fertilizer, fertilization device, etc., can solve the problem of increasing labor costs, reducing the operating efficiency of the turning machine, and unable to realize the automatic displacement control of the turning machine etc. to achieve the effect of reducing energy consumption and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

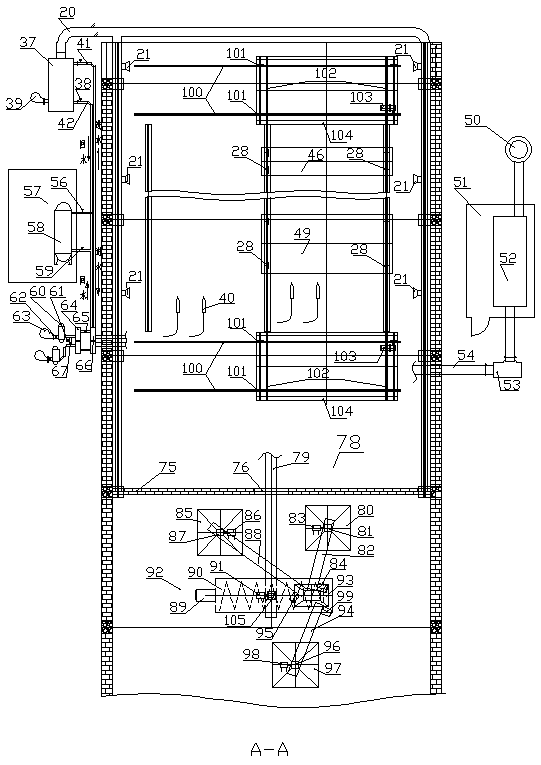

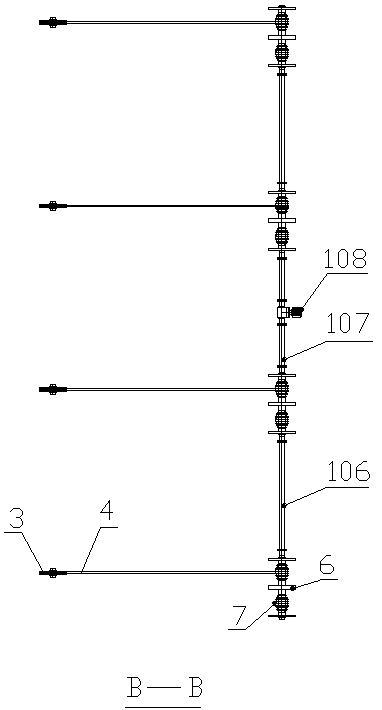

[0045] The specific implementation process of this technical solution will be described in detail below in conjunction with the accompanying drawings (1-11). The problem to be solved by the present invention is to find the sludge composting process by implementing a rapid aerobic fermentation process equipment for sludge composting and its automatic control of the process. In the early stage of the aerobic fermentation process (end of fabric), the optimal initial process parameters to promote microbial reproduction and the automatic control scheme for process equipment obtained from this process parameter, realize real-time automatic data collection, automatic recording, automatic analysis, automatic archiving and large-scale Automatic control of mechanized operation process. At the same time, it can shorten the aerobic fermentation cycle of sludge composting and reduce a lot of labor costs. Through the automatic control of this kind of process equipment and its process, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com