Ni-doped tin dioxide microporous anode, preparation method and application

A tin dioxide, anode technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the difficulty of Ti/BDD electrode preparation, electrode catalytic activity, limited surface area, influence Electrode catalytic efficiency and other issues, to achieve the effect of improving catalytic activity and mechanical stability, fast and efficient phenol, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

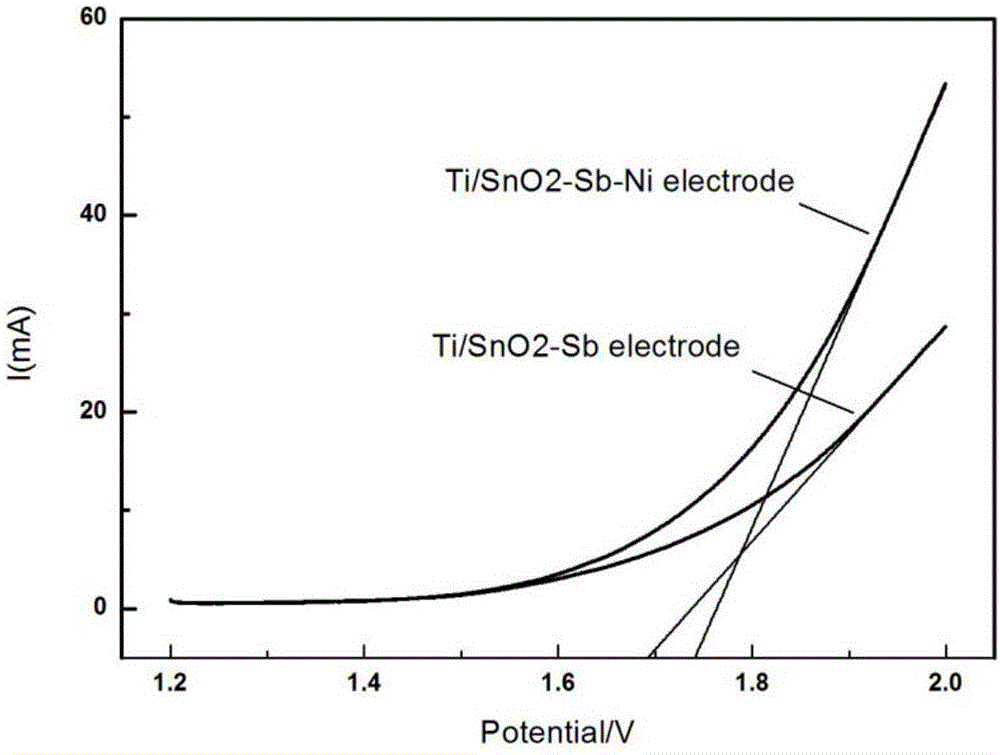

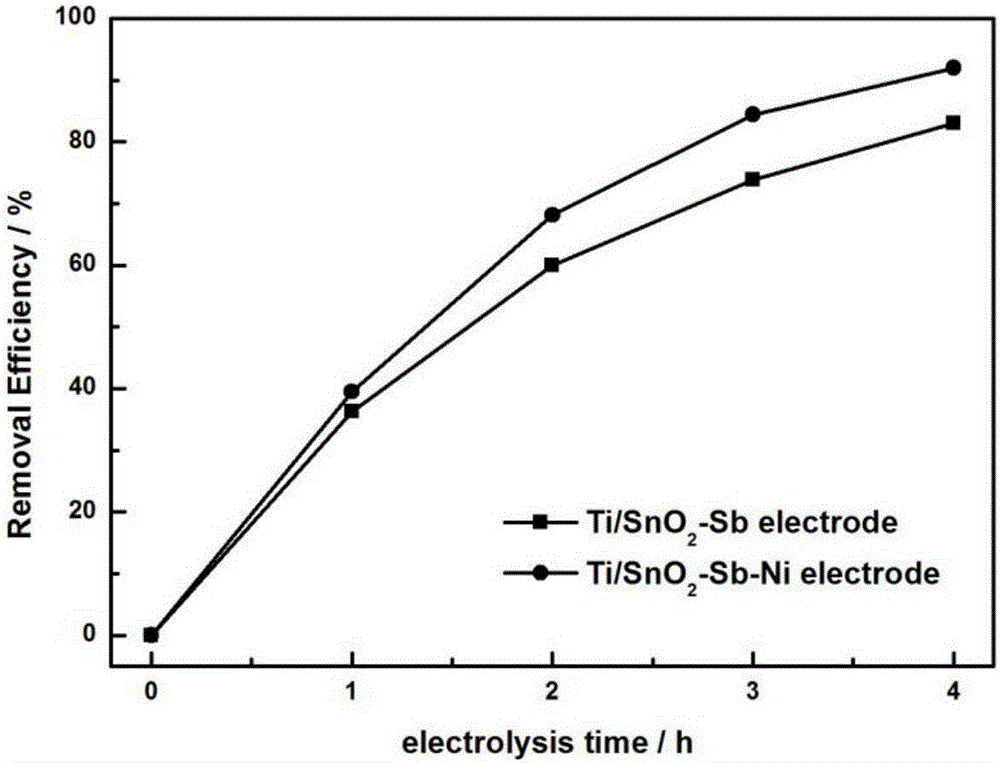

AI Technical Summary

Problems solved by technology

Method used

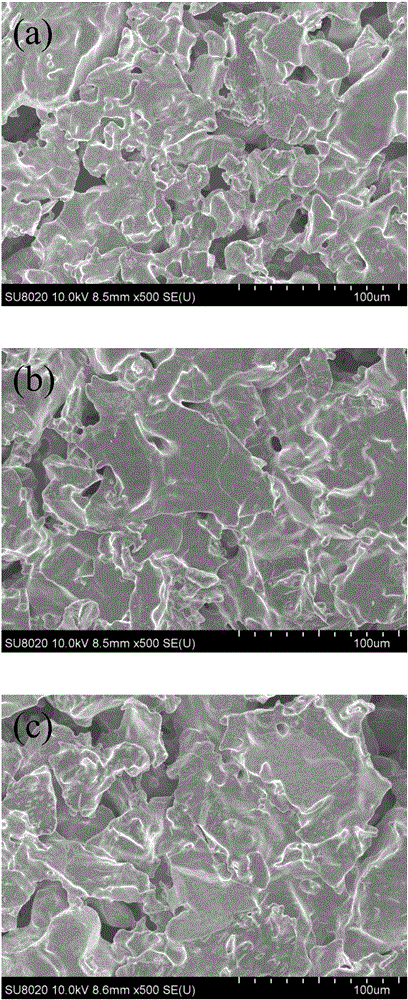

Image

Examples

Embodiment 1

[0026] 1. Preparation of electroplating solution: SbCl 3 The powder is dissolved in concentrated HCl, concentrated HCl: SbCl 3 The mass ratio is 350:9, adding a certain amount of SnCl 4 ·5H 2 O, fully dissolve with an appropriate amount of water, and then add a certain amount of NiSO 4 , Sn:Sb:Ni molar ratio is 100:9:1. Pour the citric acid into the solution, so that the citric acid in the solution is 0.1-0.5M, and ultrasonically mix it thoroughly. Then, 3-aminopropyltrimethoxysilane was added dropwise thereto, the mass percentage of 3-aminopropyltrimethoxysilane being 0.05%, and ultrasonically mixed thoroughly. Set aside for a period of time.

[0027] 2. Pretreatment of mp-Ti substrate: soak the mp-Ti board in 10% NaOH at 85°C for 0.5h to remove oil, wash it with distilled water until neutral; soak it in 5% oxalic acid solution, keep it at 85°C 0.5h, rinse with twice distilled water and set aside.

[0028] 3. Pulse composite electrodeposition: use the solution configur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com