A new type of cargo frame holder

A gripper and cargo frame technology, applied in the field of new cargo frame grippers, can solve problems such as low degree of automation, and achieve the effects of protecting equipment safety, improving handling efficiency, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

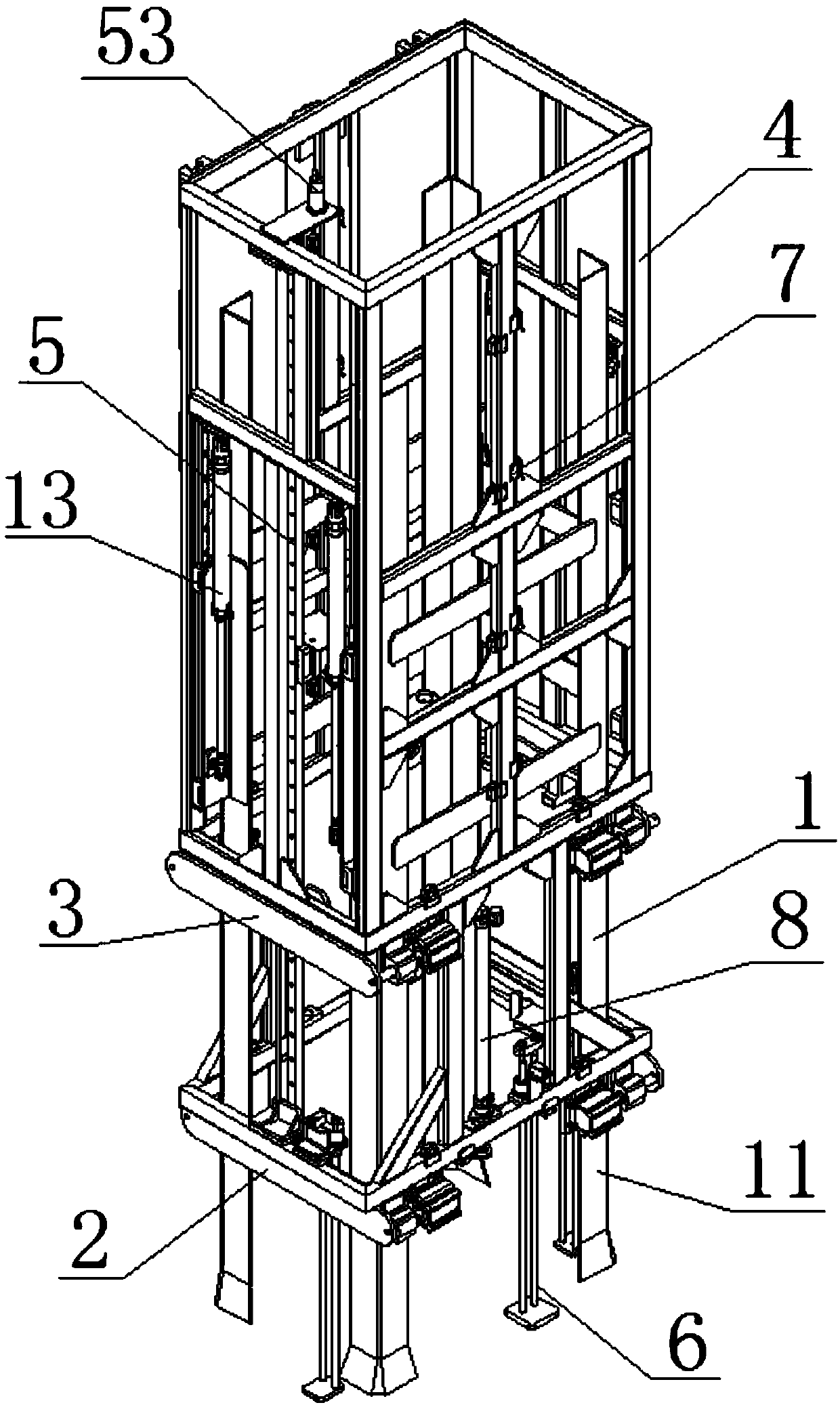

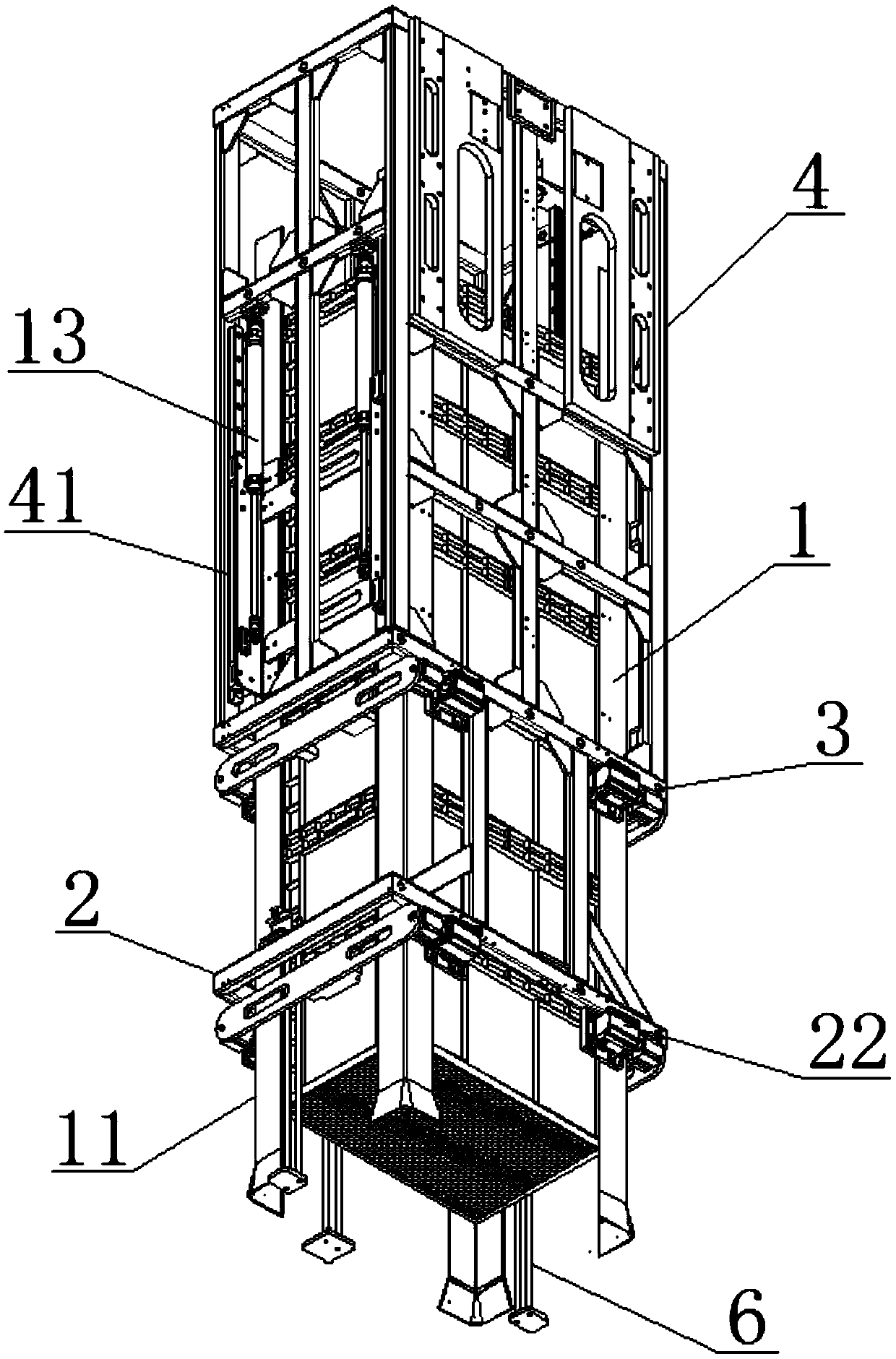

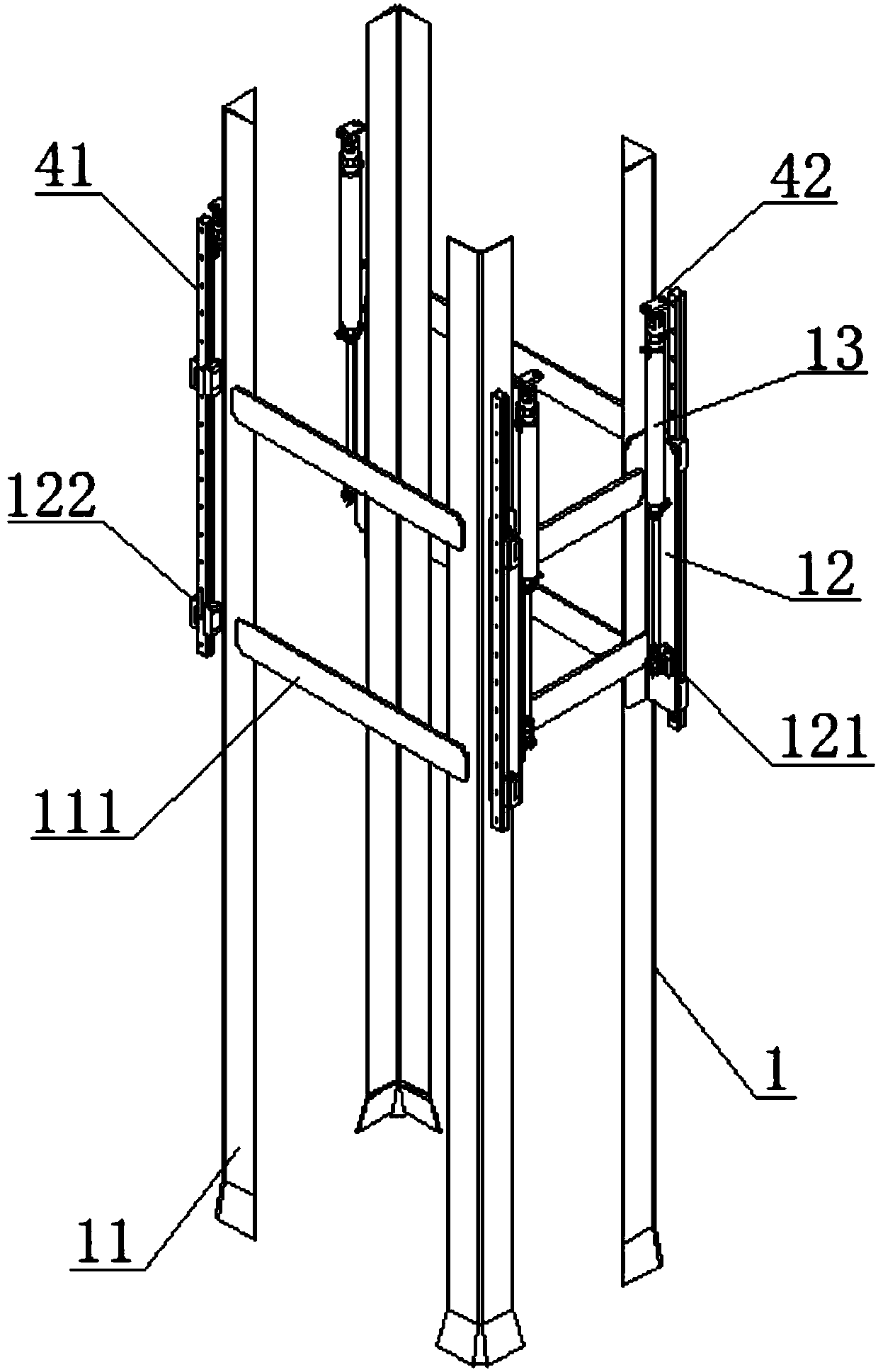

[0018] like Figure 1~6 As shown, a new type of cargo frame gripper includes a guide device 1, a lower gripper 2, an upper gripper 3, a main bracket 4, a stabilizing device 5, a deviation correction device 6, and a floor height detection device 7. The main bracket 4 It is a cuboid frame with upper and lower ends openings, the main support 4 is provided with a plurality of supporting beams and supporting vertical beams, and the first guide rails 41 are fixedly installed on the four side edge vertical beams of the cuboid main support 4, and the guide device 1 is installed Inside the main bracket 4, the guide device 1 is provided with four guide corners 11 corresponding to the four side vertical beams of the main bracket 4, and the guide corners 11 can be installed on the main bracket 4 through The first guide rail 41 slides up and down, the lower gripper 2 is fixedly mounted on the lower part of the main bracket 4, the upper gripper 3 is fixedly installed in the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com