Intelligent container system

An intelligent, container technology, applied in the field of logistics, can solve problems such as inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

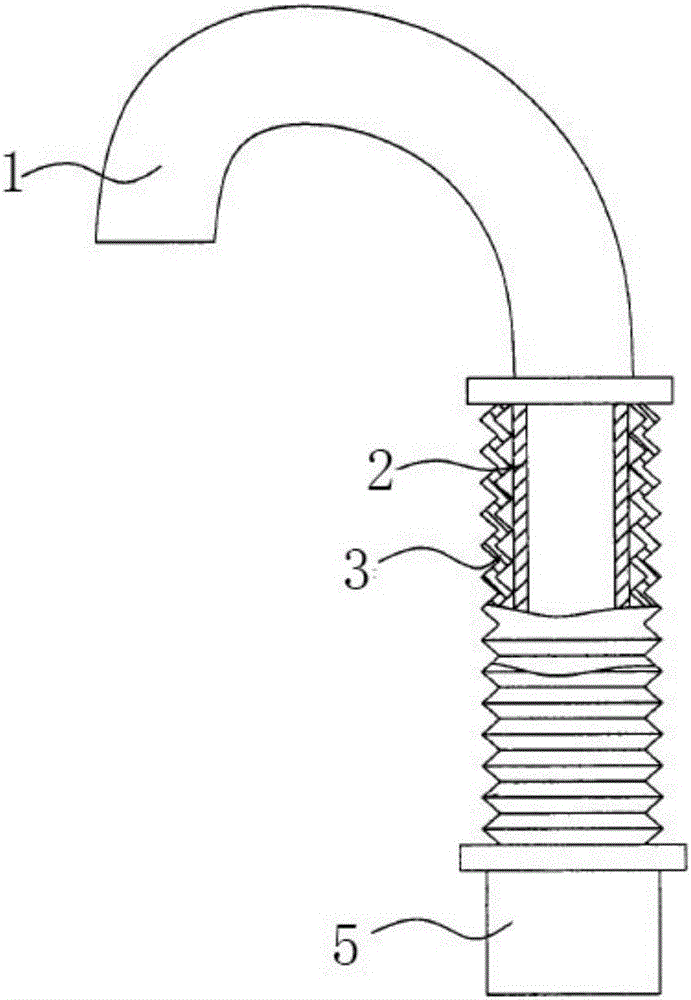

[0039] The device of the present invention comprises an induction device body 1, a total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the general induction device is connected to the cargo conveying roller. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

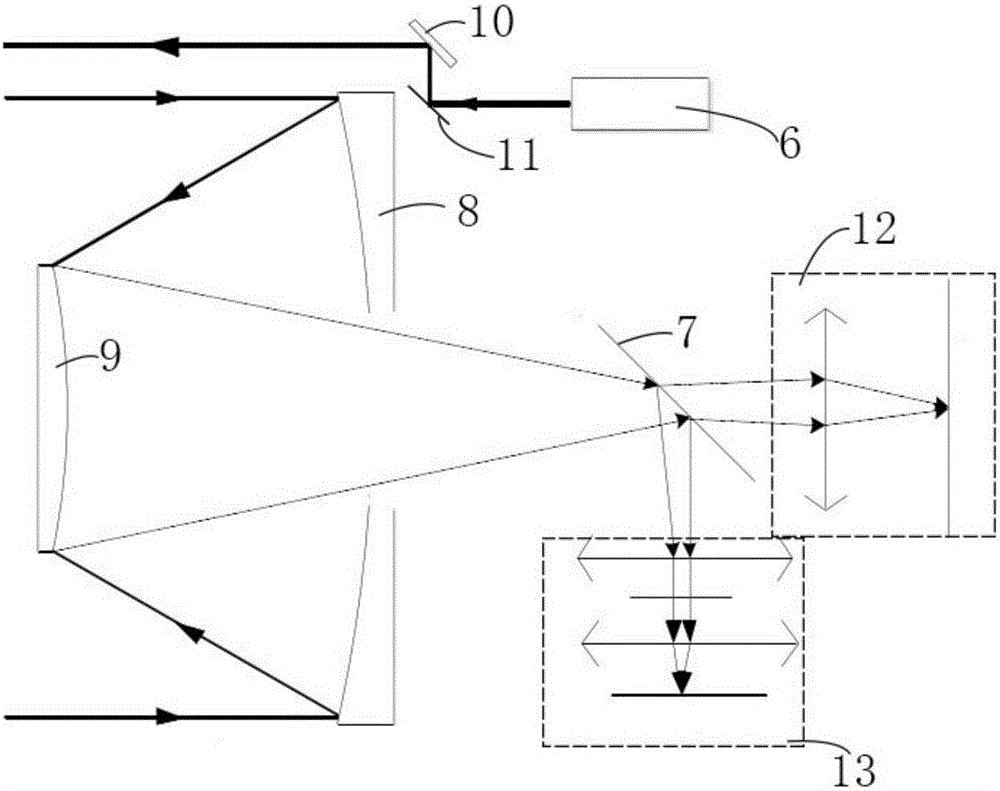

[0040] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The opti...

Embodiment 2

[0076] The device of the present invention comprises induction device body 1, total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the general induction device is connected to the cargo conveying roller. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

[0077] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The optical r...

Embodiment 3

[0113] The device of the present invention comprises an induction device body 1, a total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the general induction device is connected to the cargo conveying roller. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

[0114] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com