Preparation process of snowflake-effect packaging material

A packaging material and preparation technology, applied in the field of snowflake effect packaging materials and its preparation, can solve the problems of large paper deformation, large ink consumption, high ink cost, etc., and achieve metal texture, beautiful material pattern, and abrasion resistance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

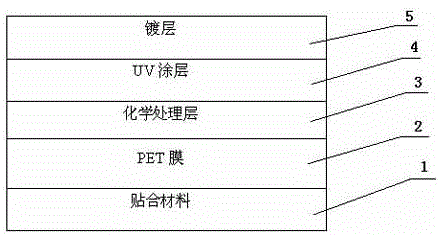

[0030] Such as figure 1 Shown, a kind of snowflake effect packaging material of the present invention comprises bonding material layer 1, PET film layer 2, chemical treatment layer 3, UV coating 4 and vacuum coating 5; Composite material layer 1, coating chemical treatment layer 3 on PET film 2, use the PET film that has been treated as base material, coat UV laser holographic coating 4 on the base material, while coating on the snowflake nickel plate Upper molding, UV curing after molding, and a layer of coating 5 is vacuum evaporated on the UV coating.

[0031] The preparation process of the above-mentioned snowflake effect packaging material mainly includes the following steps:

[0032] (1) Coating: first coat a chemical treatment layer on the PET base film (polyethylene terephthalate), and use the treated PET film as the base material;

[0033] In this step, the chemical treatment layer is selected from the UV chemical treatment layer C-1006A1A2 produced by Shanghai Weik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com