Device and method for laying wire on interlayer of laminated glass

A technology of laminated glass and intermediate layer, applied in the field of wire devices, can solve the problems of inability to lay complex patterns, low wire production efficiency, unstable product quality, etc., and achieve the effects of improving laying accuracy, improving production efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The content of the present invention will be further described below in conjunction with the accompanying drawings.

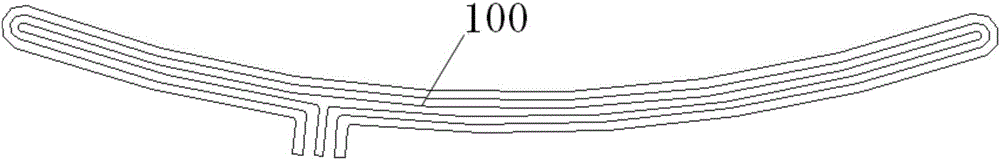

[0059] Such as figure 1 As shown, the wire 100 needs to be arranged according to the pattern in the figure to realize the functions of heating, antenna and / or decoration on the actual product; wherein, the wire 100 can be a metal wire, such as a tungsten wire. When the wire 100 is used as an antenna, it is often necessary to lay the wire 100 into a more complex pattern. There are often not only non-bending segments such as straight line segments or arc segments but also multiple turning segments in the graphs of these wires 100, such as figure 1 The middle part shown in can be regarded as a non-bending section, and the two ends can be regarded as a turning section. At the current level of technology, it is difficult to realize the traditional method of automatically laying wires by rollers or manually laying wires on the middle layer of laminated glass....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com