A method for manufacturing a plastic shell and the plastic shell obtained by the method

A production method and technology of plastic shells, which are applied to electrical components, special decorative structures, electrical equipment shells/cabinets/drawers, etc., can solve problems such as single effect and inability to achieve three-dimensional texture patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

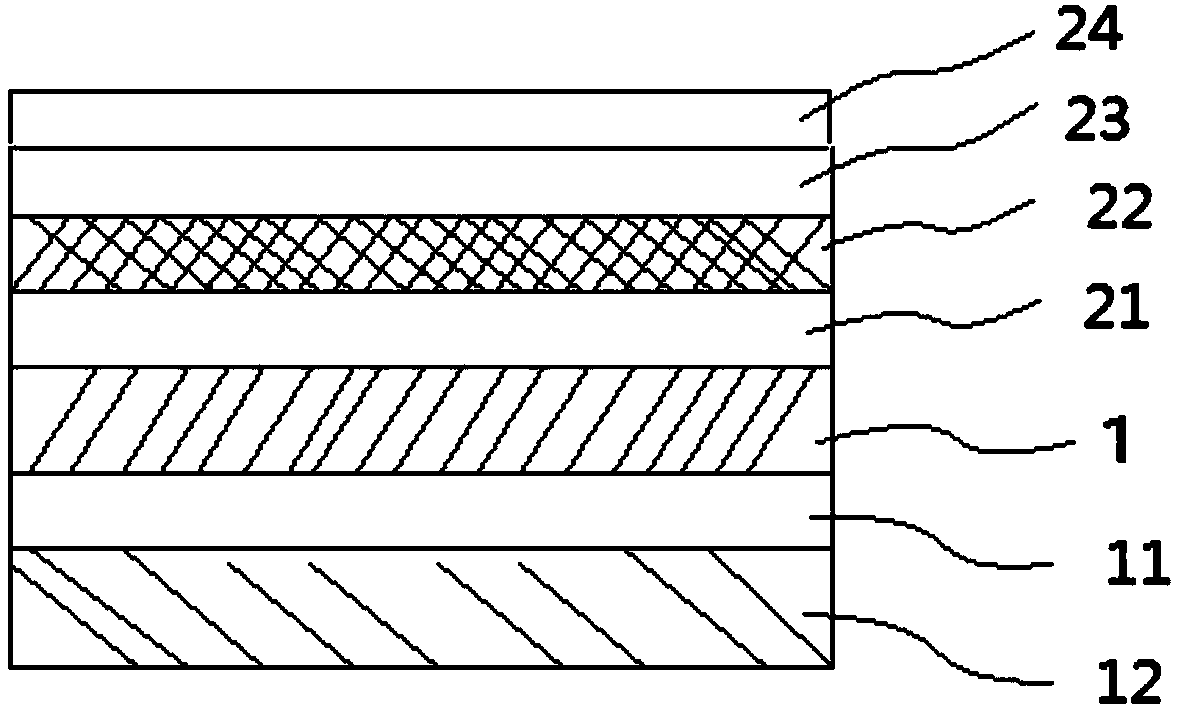

[0048] According to the manufacturing method that the application provides the plastic shell, the plastic shell is obtained, and its cross-sectional structure is as follows: figure 1 shown. The colored primer layer 11 and the first transparent topcoat layer 12 are successively sprayed on the back of the transparent plastic housing 1, and the transparent primer layer 21, the metal layer 22, the transparent middle paint layer 23 and the transparent primer layer 23 are successively sprayed on the front of the plastic housing 1. Second clear topcoat layer 24 .

[0049] The back of the transparent plastic shell 1 has a second texture pattern, the thickness of the transparent plastic shell 1 is 0.7±0.05mm, and the light transmittance is ≥70%.

[0050] The colored primer layer 11 adopts a baking-type colored primer with a thickness of 5-8 μm, and the color of the colored primer determines the color of the plastic shell.

[0051] The first transparent topcoat layer 12 is a transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com