Fixed-distance conveying, rotating and clamping device for electric tower pipe

A technology of rotating clamping device and power tower, which is applied in the direction of auxiliary device, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of simple movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

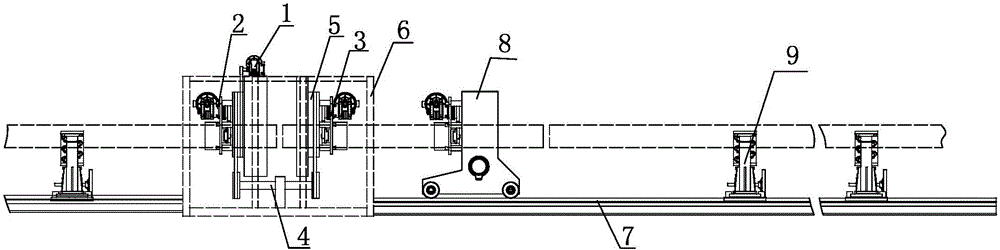

[0034] Such as Figures 1 to 8 As shown in the figure, a power tower tube fixed-distance delivery rotating clamping device is used for welding the power tower tube, which drives the rear tower tube to move forward at a fixed distance one by one, and clamps and fixes the tower tubes at the front and rear ends that need to be welded. And drive the tower tube to be welded to rotate during welding to complete the delivery and rotation during the welding process of the tower tube;

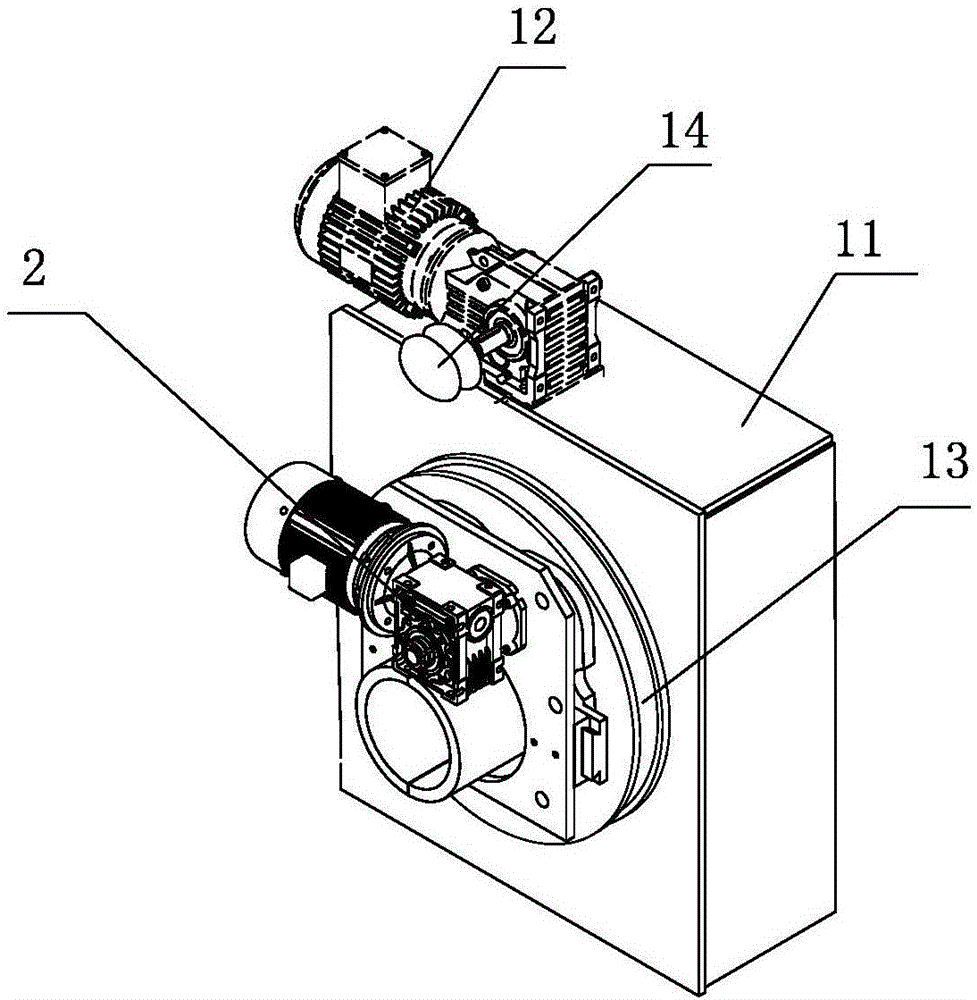

[0035]It includes a rotary clamping device, a fixed-distance moving device 8, a track 7, a lifting device 9 and a control system; the rotary clamping device is used to clamp the ends of two sections of tower tubes that need to be welded together, and realize welding During the process, the two sections of tower tubes rotate synchronously. The rotary clamping device includes a rotary power mechanism 1, a front clamping mechanism 2, a rear clamping mechanism 3, a synchronous rotation transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com