A welding protection tool for vacuum atmosphere furnace

A technology for protecting tooling and atmosphere furnaces, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as unfavorable product cleaning work, uneven product thermal conductivity, surface damage, etc., to avoid surface damage, avoid product deformation, and improve The effect of flow and exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

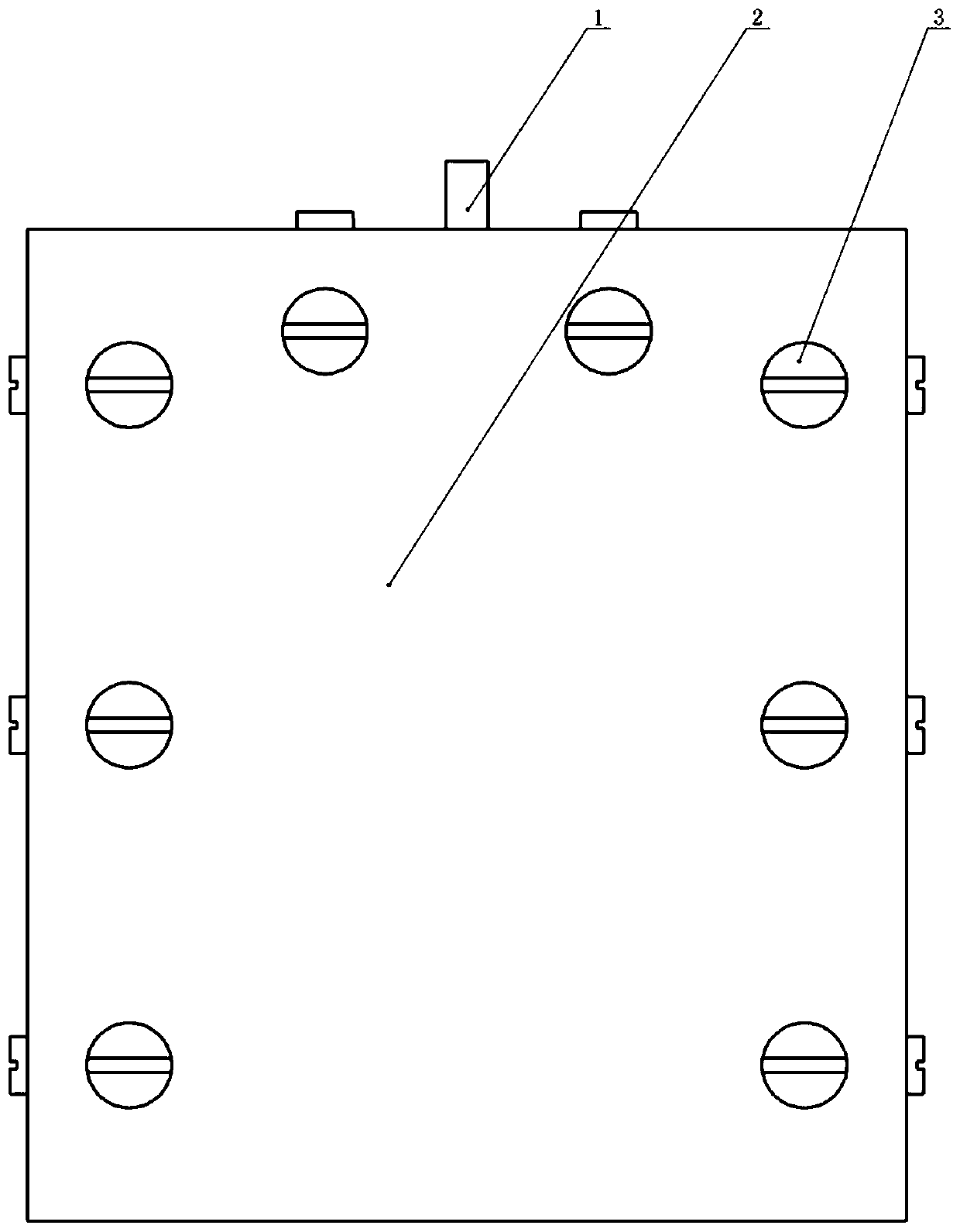

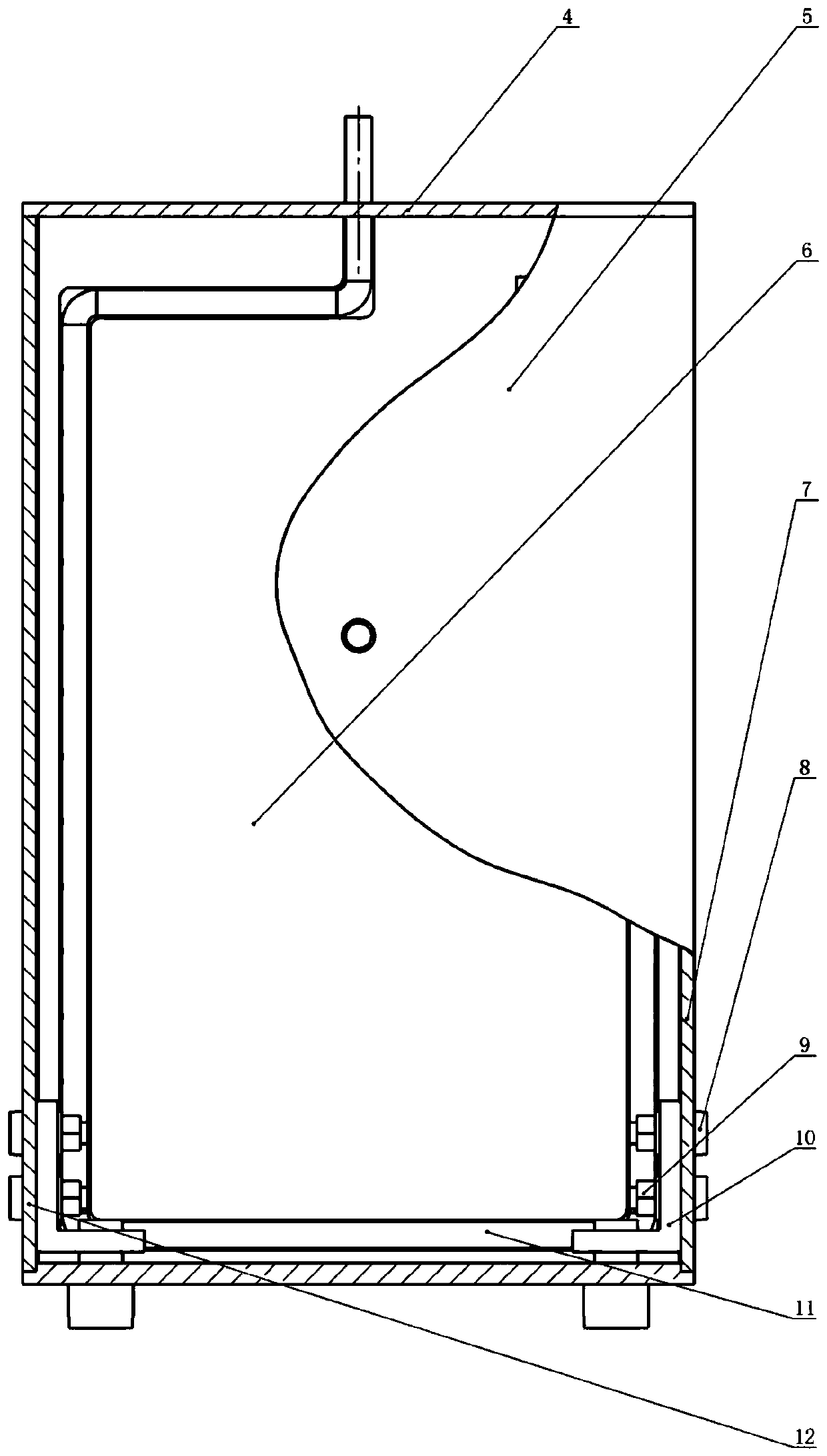

[0018] The tooling is a box body, including air outlet pipe 1, front plate 2, hexagon socket head screw 3, rear plate 4, upper plate 5, lower plate 6, left side plate 7, slotted pan head screw 8, hex nut 9 , right-angle plate 10, intake pipe 11, right side plate 12. The bottom of the hearth of the vacuum atmosphere furnace is an air inlet, on which is a thermocouple, corresponding to the two small holes on the back plate 4 of the tooling box, one of which is inserted into the thermocouple, and the other hole is connected to the air inlet pipe 11 and the air inlet . In this way, the thermocouple is equivalent to entering the inside of the tooling box, and can directly control the temperature increase; and the air intake pipe 11 guides the cold air inside the air intake hole into the inside of the tooling box, and then passes through the small opening 13 on the air inlet pipe 11, The cold air is evenly filled inside the box to achieve the purpose of controlling the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com