Manual bending tool

A manual bending and tool technology, applied in the field of wire bending, can solve the problems of easy exposure of copper wires due to insulation damage, easily damaged wires, sharp right angles, etc., to avoid burrs or breakage of insulating paint film, reduce damage, and simple structure lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

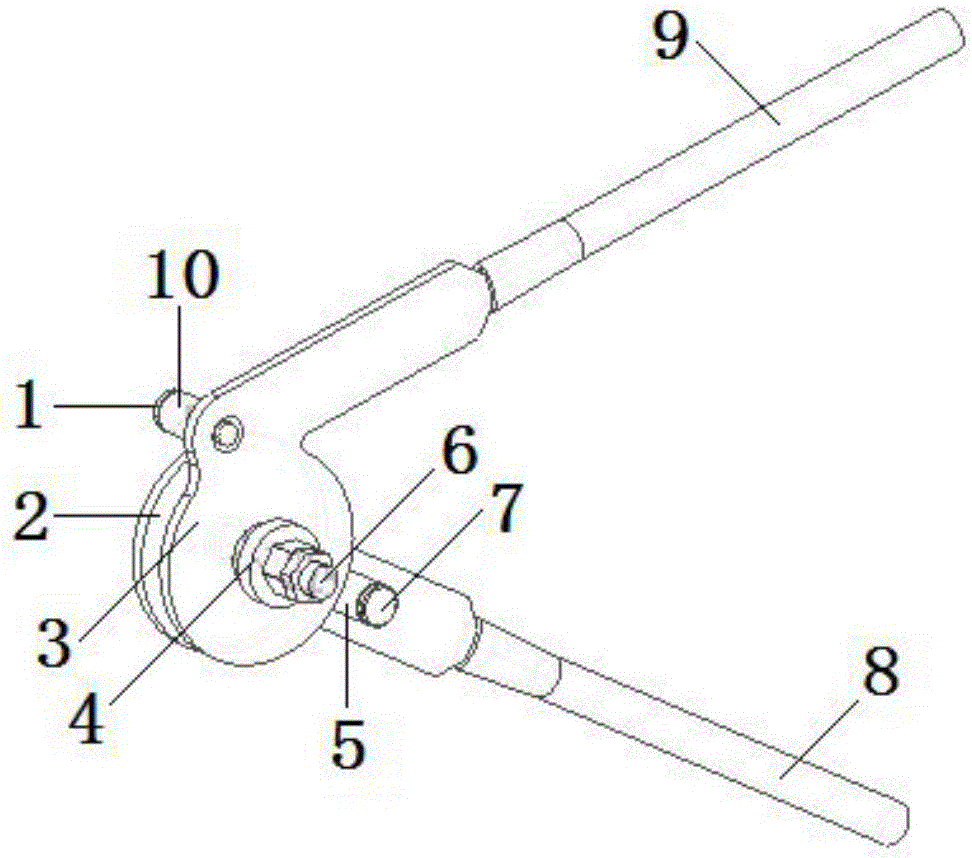

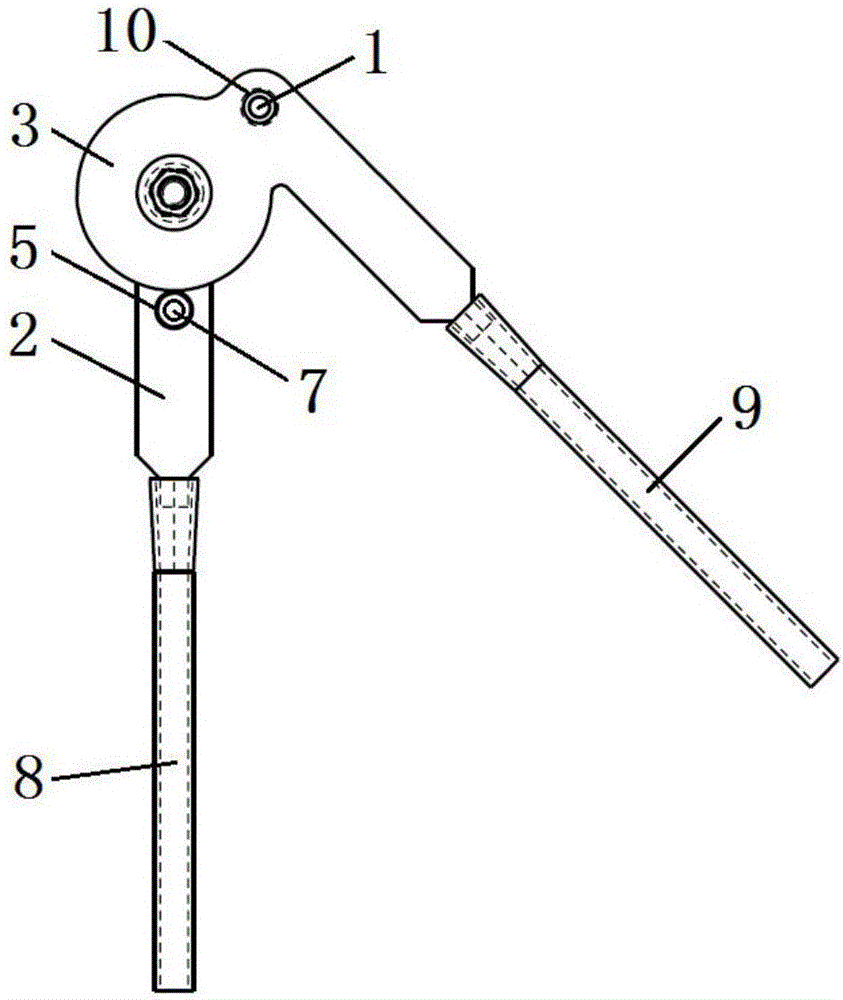

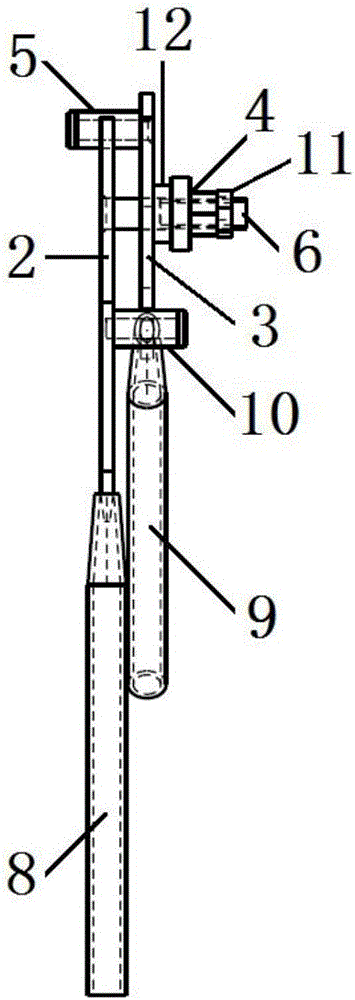

[0014] As shown in the figure, a manual bending tool includes a stud 6 arranged at the axis of the plate I2, a plate II3 that is rotatably connected to the plate I2 through the stud 6, and a plate II3 that is respectively arranged on the opposite surface of the plate I2 and the plate II3. T-pillar I7 and T-pillar II1, and handle I8 and handle II9 respectively connected to the tail ends of plate I2 and plate II3, said plate II3 can be detached from plate I2; thread I is provided near the end of stud 6, and The T nut 4 connected with the thread I, the washer 12 is provided between the T nut 4 and the plate II, the end of the stud 6 is provided with the thread II of the same type as the thread I, and a type 2 all-metal lock nut connected with the thread II 11. T-pillar set I5 and T-pillar set II10 are respectively nested on T-pillar I7 and T-pillar II1.

[0015] Unscrew the type 2 all-metal lock nut 11 and T nut 4 successively, and remove the plate II3, insert the wire between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com