Device for realizing particle suspension and rotation

A particle and shell technology, which is applied in the field of devices for realizing particle suspension and rotation, can solve problems such as difficulty in meeting material processing requirements, affecting processing efficiency, and easily polluting materials, improving product quality, improving suspension ability, and wide application fields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

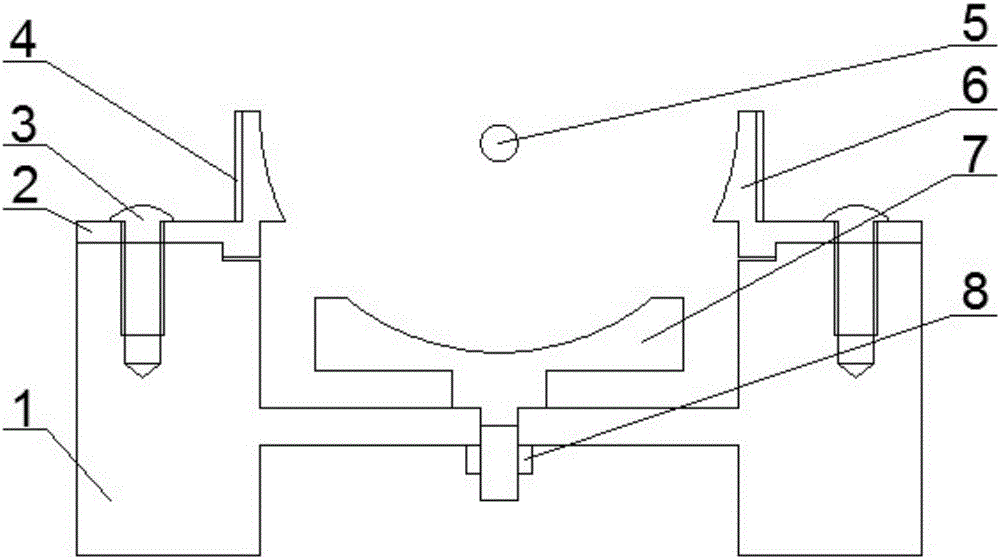

[0036] Such as Figure 1-7 As shown, the device for particle suspension and rotation based on acoustic suspension and rotating sound field in this embodiment includes a base 1, a housing 2, an ultrasonic generator and an ultrasonic reflection end 7. The longitudinal section of the base 1 is an H-shaped structure, and the base is A hollow cylinder, a circular bottom plate 1-1 is fixed on the cross section of the middle of the cylinder, wherein the outer diameter of the circular bottom plate matches the inner diameter of the cylinder. The center of base plate 1-1 forms the installation port that is used to fix ultrasonic reflection end 7, and ultrasonic reflection end 7 is fixedly connected with base plate 1-1 by fixing nut 8 and the upper end of ultrasonic reflection end 7 does not protrude the upper surface of base 1, thereby Fix the ultrasonic reflective end 7 in the base 1, the ultrasonic reflective end 7 has a spherical concave shape, and the spherical concave ultrasonic re...

Embodiment 2

[0041] Such as Figure 8-12 As shown, the device for particle suspension and rotation based on acoustic levitation and rotating sound field in this embodiment includes a base 11, a housing 21, an ultrasonic generator and an ultrasonic reflection end 61, and the base 11 includes a circular platen and a supporting platen The bracket is hollow cylindrical, the outer diameter of the platen is larger than the outer diameter of the bracket, and the structure of the base 11 is axisymmetric. The middle part of the platen is recessed to form an installation opening of the ultrasonic reflection end 61 , and the ultrasonic reflection end 61 is fixedly connected to the top of the base 11 through the fixing nut 71 fixed in the installation opening. The upper surface of the ultrasonic reflection end 61 is spherically concave, wherein the bottom of the concave structure is higher than the upper surface of the base 11 . An ultrasonic generator is arranged directly above the ultrasonic reflec...

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that other even-numbered ring-shaped piezoelectric ceramic sheets are evenly distributed on the outer surface of the ultrasonic traveling wave generator section, which can be adjusted according to the actual requirements for ultrasonic rotating traveling wave parameters. it is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com