Multi-cutter bit soybean milk machine

A soymilk machine and multi-cutter technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of small cutting force, affecting the taste of drinks, and long crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

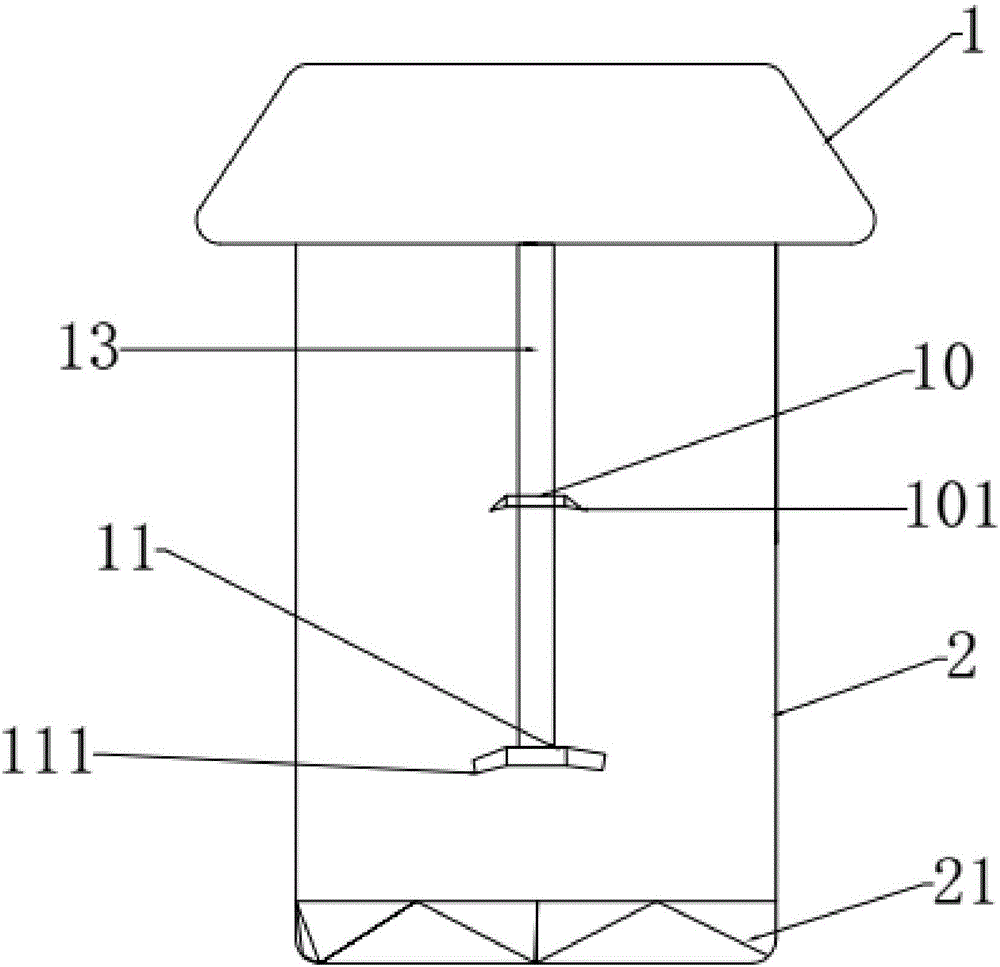

[0014] Such as figure 1 As shown, a multi-cutter head soybean milk machine includes a cup body part 2 and a machine head part 1. The machine head part 1 is buckled on the cup body part 2, and a heating element 21 is arranged at the bottom of the cup body part for pulverizing The liquid is cooked to form delicious soymilk or paste.

[0015] The motor shaft 13 is arranged at the center position of the head part 1, and the bottom of the motor shaft 13 is connected with a fixed cutter head 11, and the fixed cutter head 11 is evenly distributed with three blades 111 bent upwards. The motor shaft rotates at the same speed to pulverize beans or cereals, while the upwardly curved blade 111 beans or cereal crushing liquid flows upwards. The motor rotating shaft 13 is also covered with a sleeve, the preferred movable sleeve is a differential movable sleeve, and three blades 101 are evenly connected on the movable sleeve, and the blade 101 and the sleeve form a movable cutter head 10, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com