Method for synchronously reducing contents of arsenic and copper in walnut protein

A technology of walnut protein and copper content, which is applied in plant protein processing, food adsorption, food processing, etc., can solve the problems of walnut protein edible safety and achieve the effect of mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Take 100 kg of walnut protein powder, add 960 kg of drinking water, and mix well; (2) Replace chelation: add 3.6 kg of malic acid, then adjust the pH of the slurry to 3.4 with 3.0mol / L hydrochloric acid, add 320 grams of chlorine Zinc chloride, mixing, keep 3.4 hours under 52 ℃, constantly stir during, and stirring speed is 4400 rev / mins; (3) adsorption reaction: add 3.6 kilograms of microcrystalline cellulose (average particle diameter is 340 meshes) in walnut protein slurry ), stirred at 52°C for 50 minutes, and the stirring speed was 4800 rpm; (4) solid-liquid separation: solid-liquid separation was carried out to remove insoluble solids; (5) tempering: adjust the pH of the walnut protein slurry to within 15 minutes 6.5; (6) Sterilization, dehydration and drying: the slurry is sterilized, then dehydrated and dried to obtain the product.

Embodiment 2

[0018] (1) Take 100 kg of walnut protein powder, add 960 kg of drinking water, and mix well; (2) Replace chelation: add 3.6 kg of malic acid, then adjust the pH of the slurry to 3.4 with 3.0mol / L hydrochloric acid, add 320 grams of chlorine Zinc, mixed, kept at 52 ° C for 3.4 hours, during which the stirring speed was 4400 rpm; (3) tempering: adjust the pH of the walnut protein slurry to 6.5 within 15 minutes; (4) sterilization, Dehydration and drying: the slurry is sterilized, then dehydrated and dried to obtain the product.

Embodiment 3

[0020] (1) Take 100 kg of walnut protein powder, add 960 kg of drinking water, and mix well; (2) Chelation: add 3.6 kg of malic acid, then use 3.0mol / L hydrochloric acid to adjust the pH of the slurry to 3.4, and keep it at 3.4 at 52°C hour, during which the stirring speed was 4400 rpm; (3) tempering: adjust the pH of the walnut protein slurry to 6.5 in 15 minutes; (4) sterilization, dehydration and drying: the slurry was sterilized, and then Dehydration and drying to obtain the product.

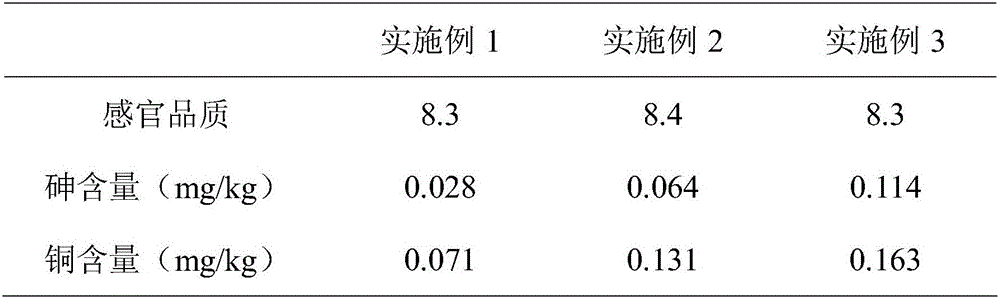

[0021] Effect analysis of different embodiments:

[0022]

[0023] Note: The higher the score of sensory quality, the better the taste

[0024] Compared with Examples 2 and 3, the arsenic and copper contents of Example 1 processed by the present invention were reduced to 0.028mg / kg and 0.071mg / kg respectively; Basically the same.

[0025] The present invention uses zinc ions to replace and chelate under specific circumstances, and the content of arsenic and copper decreases; after cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com