Multi-channel T/R assembly testing device and method

A technology of component testing and testing methods, applied in electrical components, transmission monitoring, transmission systems, etc., can solve the problems of difficulty in debugging, heavy workload, large switch combination, high labor cost, etc., to reduce scale and complicate test channels The effect of reducing the difficulty of development and improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and embodiments:

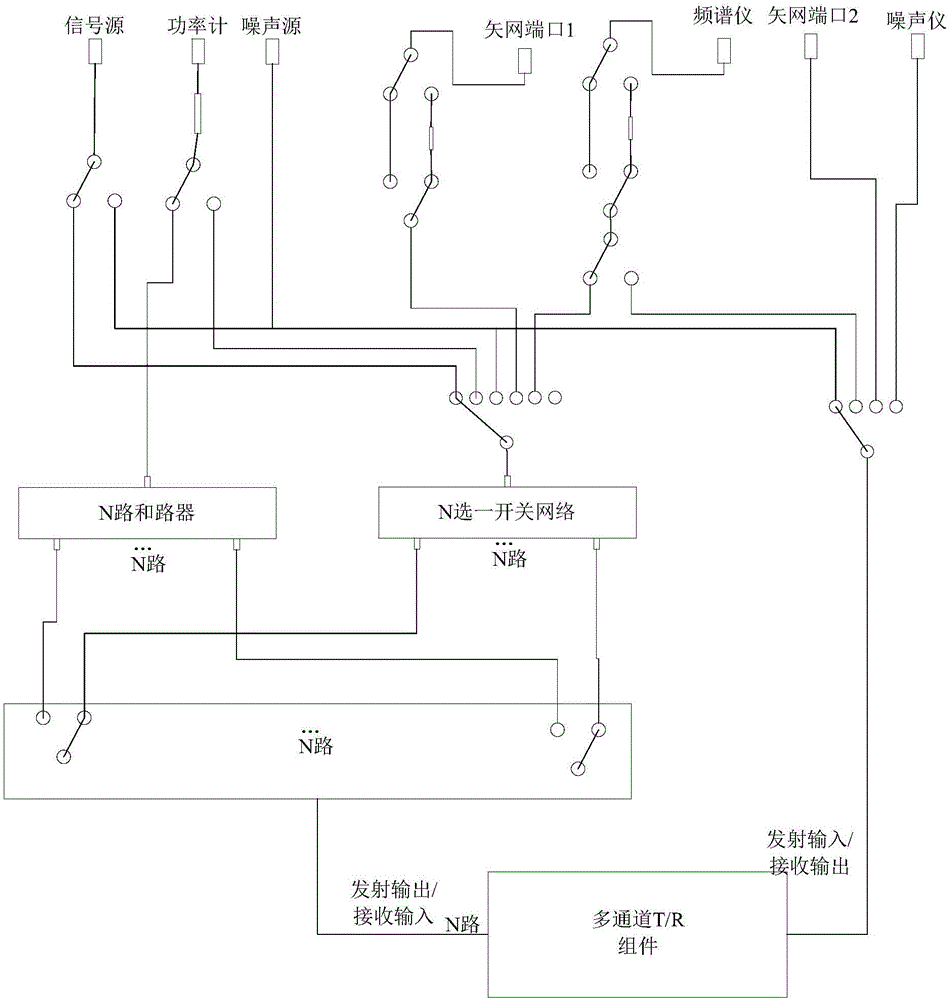

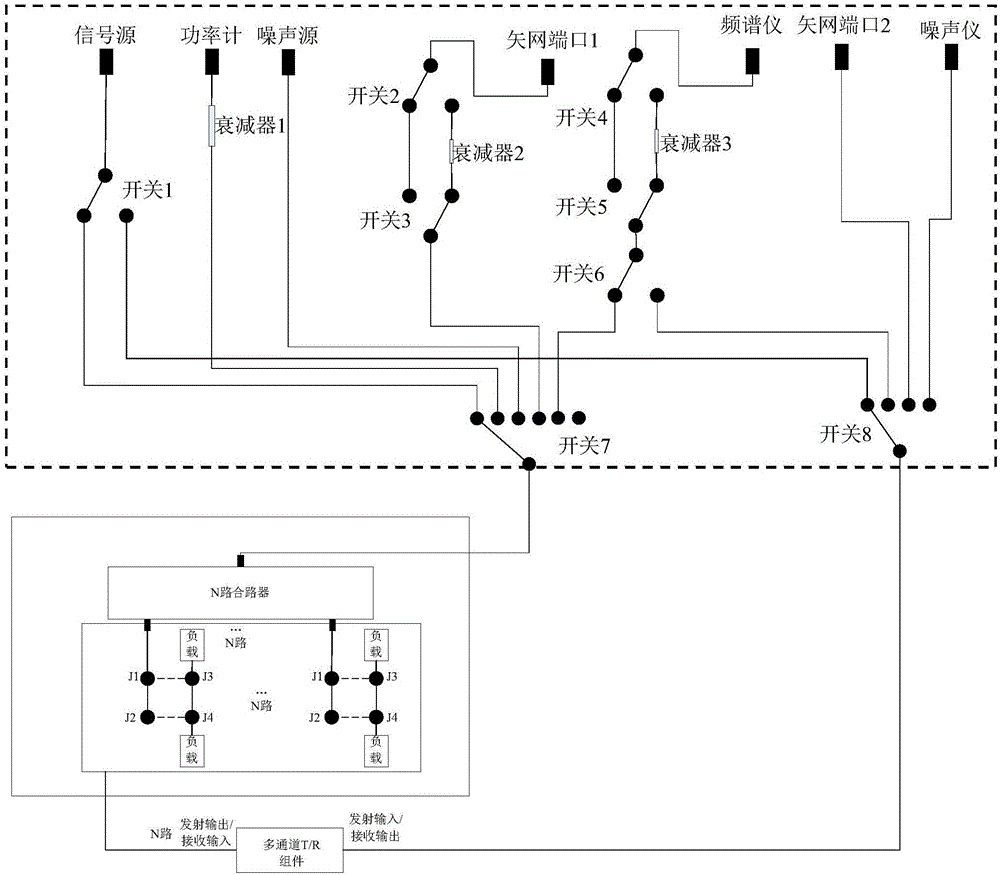

[0038] figure 2 It is a schematic diagram of the structure of the multi-channel T / R component testing device of the present invention. in figure 2 In the middle, vector port 1 and vector port 2 are the first vector port and the second vector port, respectively.

[0039] Such as figure 2 The multi-channel T / R component test device shown includes:

[0040] Transceiving signal separation network, the transceiving signal separation network includes at least one combiner, and each branch end of the combiner is connected to the transmit output / receive input end of the multi-channel T / R component through a four-port network. The transmitting input / receiving output end of the channel T / R component is respectively connected to the T / R component performance test instrument through the instrument distribution network; the combiner of the combiner is also separately connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com