Improved analytical model of motor stator core vibration induced by magnetostriction

A motor stator and stator core technology, which is applied in electrical digital data processing, instrumentation, design optimization/simulation, etc., can solve the problem of long calculation time, large computer resources, and inability to calculate the vibration displacement, stress and strain of the motor stator core yoke distribution characteristics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

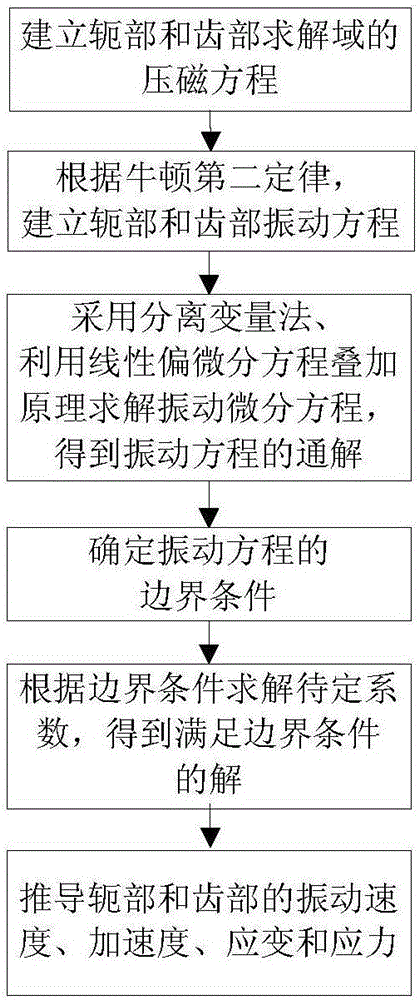

Method used

Image

Examples

Embodiment

[0147] The invention uses the finite element method to verify the analytical calculation model of the vibration of the stator iron core of the motor caused by magnetostriction. A 2.1kW radial flux amorphous alloy permanent magnet motor is taken as an example for quantitative analysis. The rated frequency of the 2.1kW motor is 267Hz, with 8 poles and 36 slots. Both methods use the same performance parameters for analysis. The electromagnetic field of the permanent magnet motor is analyzed by 2D finite element, and the quarter-cycle model of the motor is established, such as Figure 5 shown. The tangential and radial magnetic flux density curves of the position of point B of the yoke of the stator core of the motor with time are calculated as follows: Image 6 As shown, the variation curve of radial and tangential magnetic flux density with time at the position of point A of the teeth of the stator core of the motor is as follows: Figure 7 shown. from Image 6 and 7 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com