A one-cable dual-core lc-type optical fiber connector

An optical fiber connector and connector technology, which is applied to instruments, optics, light guides, etc., can solve the problems of damage to optical fiber active connectors, small operation space, troublesome replacement of polarity, etc., to achieve simple and reliable structure, improve use density, save money The effect of manipulating the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

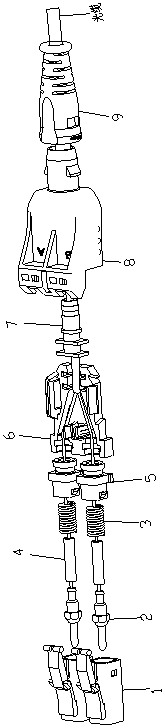

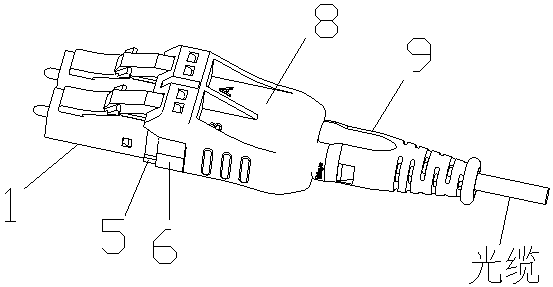

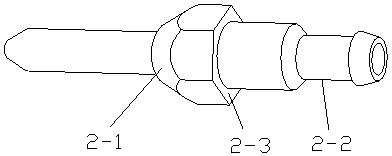

[0030] With reference to the drawings, a one-cable dual-core LC optical fiber connector is characterized by including a main bracket 1, a ferrule assembly 2, a spring 3, a heat shrink protection tube 4, an inner bracket 5, a base 6, a tail handle 7, and a shell 8. The tail sleeve 9; the ferrule assembly 2, the spring 3 and the heat-shrink protective tube 4 are inside the main bracket 1 and the inner bracket 5; the connector assembly light cable passes through the tail sleeve 9, the outer shell 8 and the tail handle 7. Peel off the base 6 into two cores, pass through the two inner brackets 5, and then pass through the heat-shrink protection tube 4, the spring 3, and end with the ferrule assembly 2. The heat-shrink tube 4 is heat-shrinked in the insert On the cylindrical surface 2-2 of the core assembly 2, the spring 3 is installed between the rear end surface 2-3 of the insert core assembly 2 and the inner end surface 5-3 of the inner bracket 5, and the front end surface 2-1 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com