A method for preparing high-purity manganese phosphate from low-grade rhodochrosite leaching solution

A high-purity manganese phosphate and rhodochrosite technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low electrolysis efficiency, complex types of impurities, and high content, and achieve high-efficiency separation, low impurity content, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The concentration of the sulfuric acid leaching solution of rhodochrosite is 100g / L. Measure 25ml of the leaching solution and place it in the reaction vessel. Add sodium phosphate solution with a concentration of 20g / L until the pH of the solution in the reaction vessel is about 3.5. Magnetically stir for 1 hour and filter. Obtain a primary manganese sulfate solution; continue to add a sodium phosphate solution with a concentration of 20 g / L, control the pH of the solution to about 4.0, magnetically stir at 25° C. for 2 hours, filter, wash, and dry to obtain manganese phosphate.

[0016] The total content of impurities in the obtained manganese phosphate is less than 0.05%, of which the content of iron is less than 0.04%; the content of aluminum is less than 0.01%; the content of heavy metals is less than 0.01%; the content of calcium and magnesium is less than 0.01%.

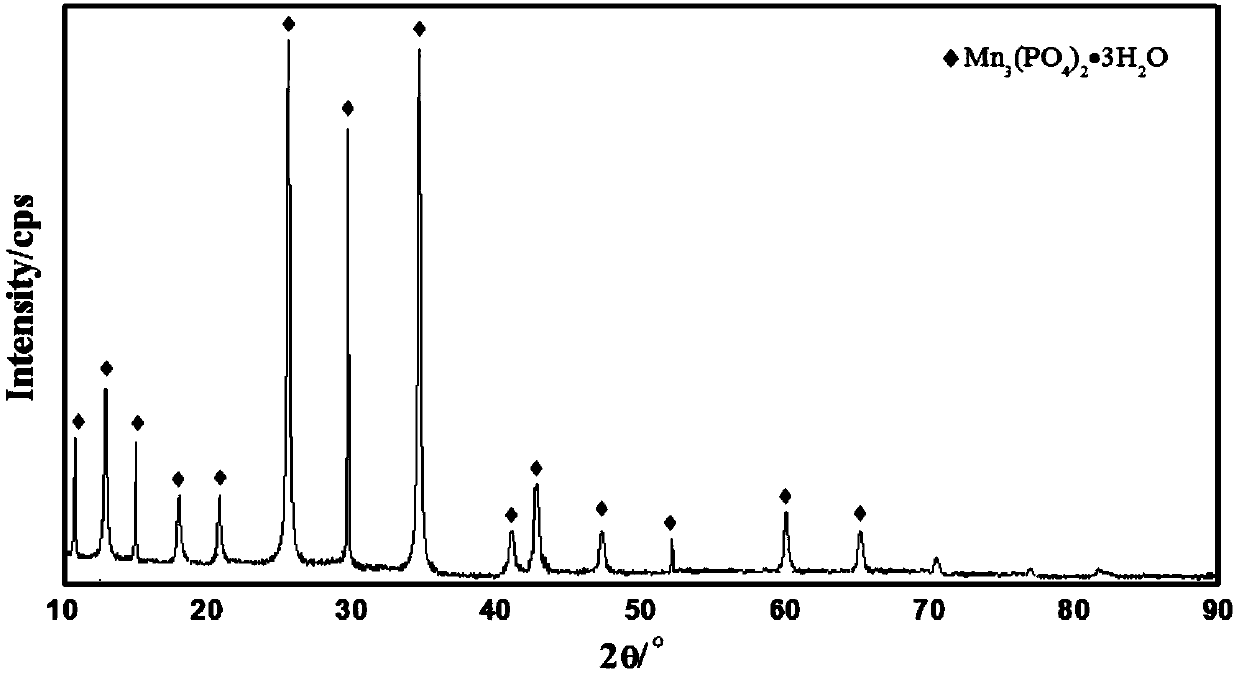

[0017] figure 1 It is the XRD pattern of the synthesized high-purity manganese phosphate, and no obvious i...

Embodiment 2

[0019] The concentration of the sulfuric acid leaching solution of Rhodochrosite is 80g / L. Measure 25ml of the leaching solution and place it in the reaction vessel. Add 15g / L sodium phosphate solution until the pH of the solution in the reaction vessel is about 3.0. Magnetically stir for 1h and filter. Obtain a primary manganese sulfate solution; continue to add a sodium phosphate solution with a concentration of 15 g / L, control the pH of the solution to about 4.5, stir magnetically at 70°C for 2 hours, filter, wash, and dry to obtain manganese phosphate.

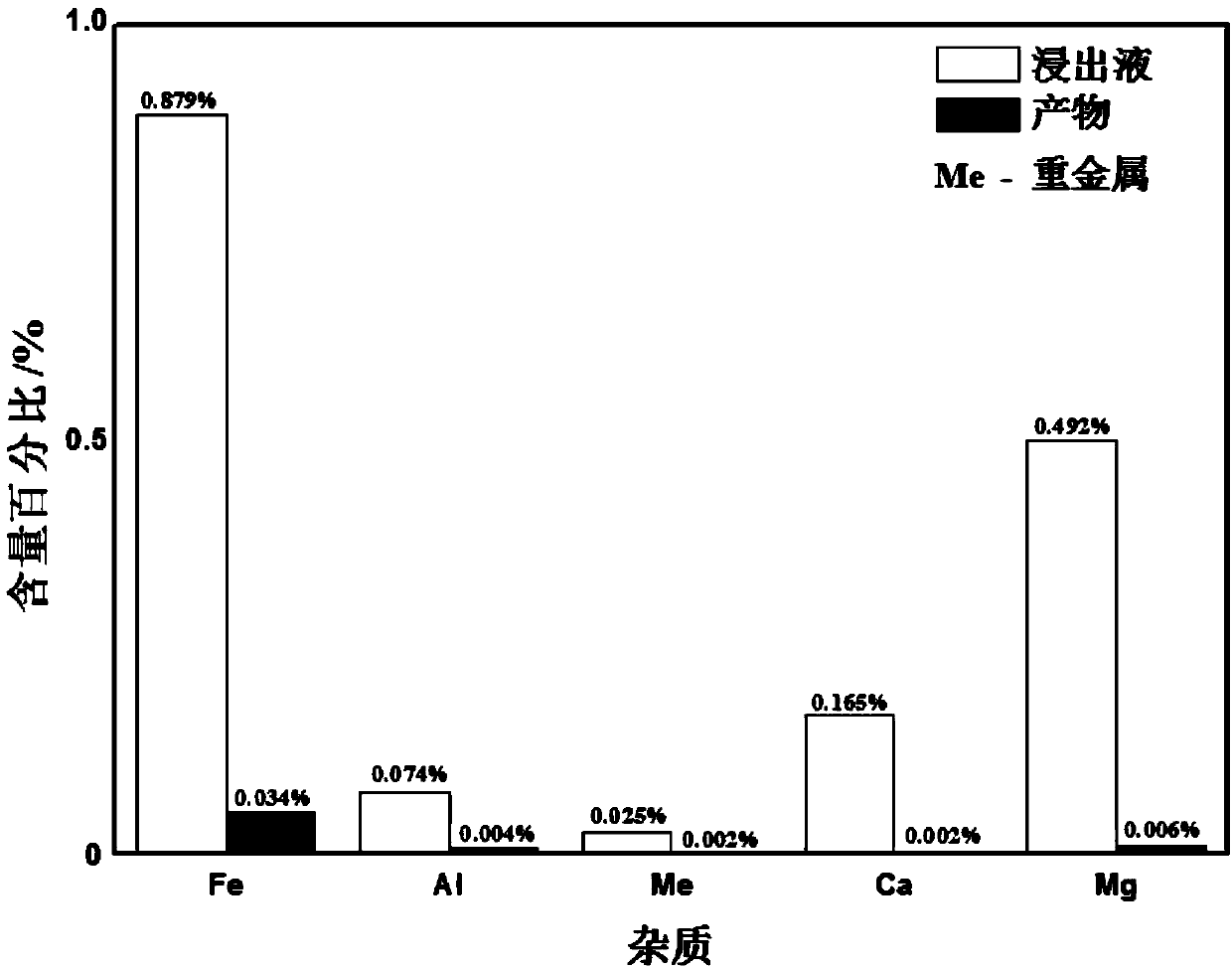

[0020] figure 2 It is a bar graph comparing the ICP analysis results of the synthesized high-purity manganese phosphate and the impurity content of the rhodochrosite leaching solution. The total impurity content in manganese phosphate synthesized by the method of the present invention is 0.048%, which is less than 0.05%; the content of impurity iron is 0.034%, which is less than 0.04%; and the content of aluminum, calcium, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com