In-line fermentation automatic batching system and batching method

An automatic batching and in-line technology, applied in the field of fermentation, to achieve the effects of compact equipment structure, high equipment operation stability, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

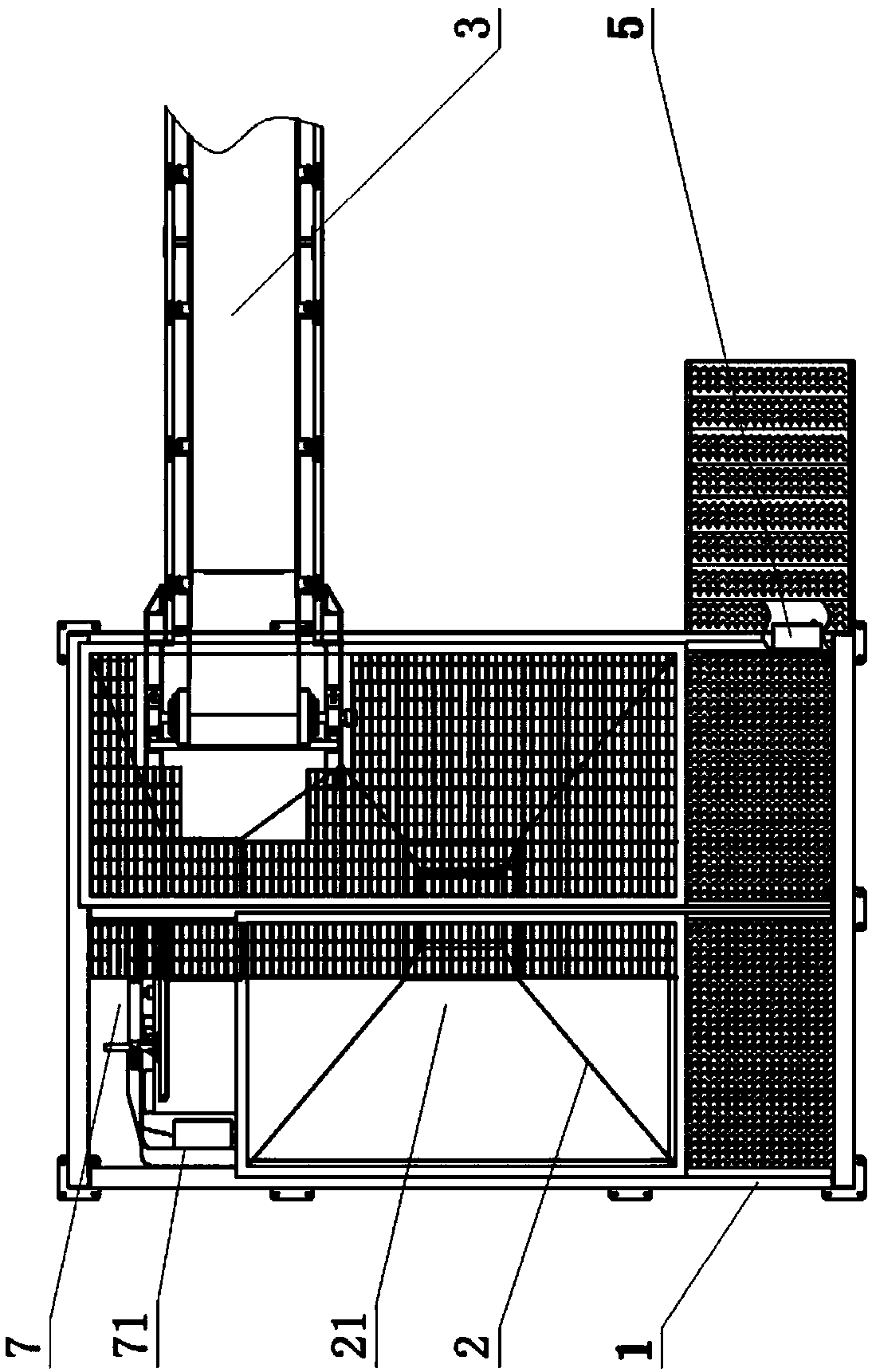

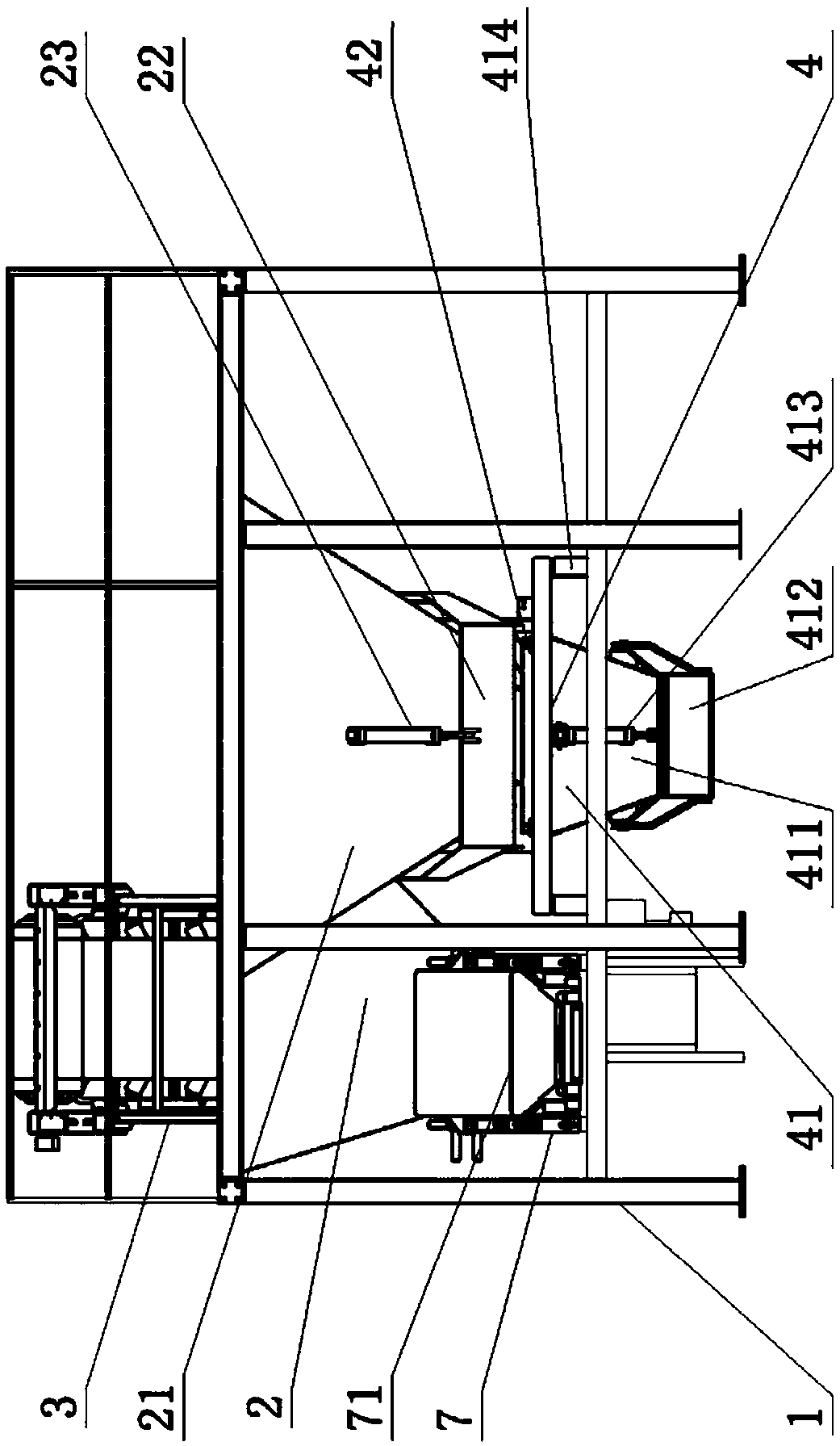

[0075] see Figure 1 to Figure 5 As shown, an in-line fermentation automatic batching system in Embodiment 1 of the present invention is mainly composed of a support frame 1, a feeding bin 2, a recycled material conveying device 3, a weighing device 4, and a system controller 5; the feeding bin 2 and weighing device 4 are installed on the support frame 1, the system controller 5 is installed on the support frame 1, the feeding bin 2 is installed above the weighing device 4, and the recycling The output end of the material conveying equipment 3 is connected above the feeding bin 2, and the system controller 5 is electrically connected with the feeding bin 2 and the weighing device 4; the feeding bin 2 is composed of a bin body 21, a bin bottom door 22 and a bottom The door opening and closing actuator 23 is formed. The bottom door 22 of the bin is hinged below the bin body 21 through a pin shaft to close the discharge opening below the bin body 21. The bottom door opening and c...

Embodiment 2

[0085] Such as Figure 6 , Figure 7 As shown, the second embodiment of the automatic batching system for fermentation of the present invention is similar to the first embodiment, the difference is that:

[0086] In order to make the organic raw material can be put into the described feeding bin 2 more conveniently, a material lifting device 6 is installed at the front end of one of the fresh organic material feeding bins 2; the material lifting device 6 is an intermittent bucket elevator; in addition, Depending on the actual working environment, belt conveyors, screw conveyors and other conveying equipment can also be used instead.

[0087] In order to avoid that the weighing hopper 41 of the weighing device 4 is directly installed above the material receiving functional unit of the fermentation equipment or fermentation system to form a restriction on the movement of the material receiving functional unit, by adding a push mechanism on the weighing device 4 43 realizes the...

Embodiment 3

[0089] Such as Figure 8 As shown, the third embodiment of the in-line fermentation automatic batching system of the present invention is similar to the first and second embodiments, the difference is that:

[0090] The current front-end fermentation equipment or fermentation system is a model with a large processing capacity, and the amount of fermented clinker that needs to be packaged and processed every day is relatively large. The clinker packaging and conveying equipment 7 is connected to the rear end of the belt conveyor and above the feeding bin 2 , and an automatic weighing and packaging equipment 8 is connected to the end of the clinker packaging and conveying equipment 7 . The clinker packaging conveying equipment 7 is a belt conveyor. In order to facilitate the switching of the materials conveyed by the recycled material conveying equipment 3 between the feeding bin 2 and the clinker packaging conveying equipment 7, it can also be set between the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com