Laundry sheet and preparation method thereof

A laundry tablet, weight percentage technology, applied to chemical instruments and methods, detergent powder/flake/sheet, detergent materials, etc., can solve the problems of fluorescent whitening agents that are harmful, and achieve easy industrial production and convenient use , Ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

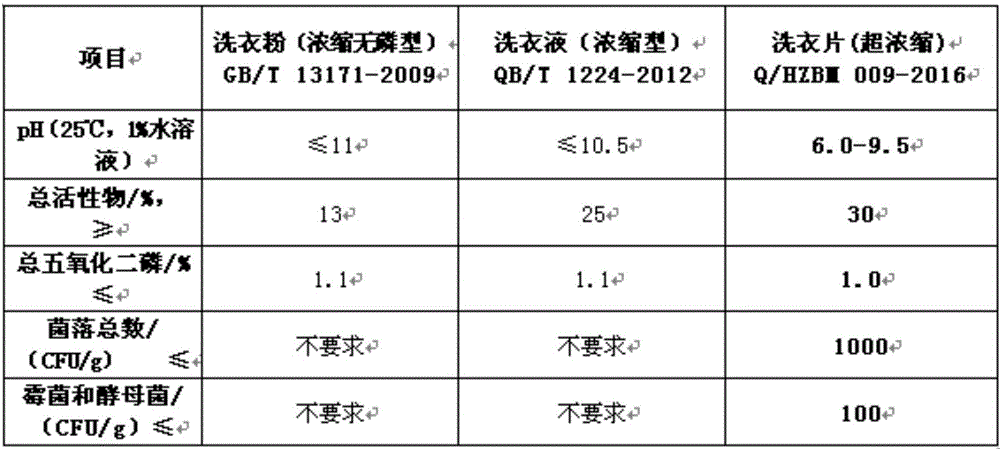

Image

Examples

Embodiment 1

[0029] A kind of laundry sheet, its component and raw material weight percent are:

[0030] Tea saponin 2%,

[0031] Surfactant 38%,

[0032] Disintegrant 15%,

[0033] Adhesive 15%,

[0034] Lubricant 6%,

[0035] Flavor 3%

[0036] The balance of water is solvent.

[0037] In this example, the surfactants are sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium laureth sulfate and cocamide DEA, each in a weight ratio of 10:6:2: 1;

[0038] In this embodiment, the disintegrant is dry starch.

[0039] In this embodiment, the binder is cellulose and polyvinyl alcohol, each in a weight ratio of 1:9.

[0040] In this embodiment, the lubricant is magnesium stearate and silicon dioxide in a weight ratio of 1:5.

[0041] The invention provides a preparation method of laundry tablets, comprising the following steps:

[0042] (1) The surfactant and the saponin are added to hot water according to the weight percentage and mixed and stirred to form a mixture A;

[00...

Embodiment 2

[0049] A kind of laundry sheet, its component and raw material weight percent are:

[0050] Tea saponin 5%,

[0051] Surfactant 40%,

[0052] Disintegrant 10%,

[0053] Adhesive 10%,

[0054] Lubricant 12%,

[0055] Flavor 3%,

[0056] The balance of water is solvent.

[0057] In this example, the surfactants are sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium laureth sulfate and cocamide DEA, each in a weight ratio of 10:5:3: 1;

[0058] In this embodiment, the disintegrant is dry starch.

[0059] In this embodiment, the binder is polyvinyl alcohol.

[0060] In this embodiment, the lubricant is glycerin, mineral oil, and silicon dioxide in a weight ratio of 5:2:1.

[0061] The invention provides a preparation method of laundry tablets, comprising the following steps:

[0062] (1) The surfactant and the saponin are added to hot water according to the weight percentage and mixed and stirred to form a mixture A;

[0063] (2) Weigh the original disintegra...

Embodiment 3

[0068] A kind of laundry sheet, its component and raw material weight percent are:

[0069] Tea saponin 15%,

[0070] Surfactant 35%,

[0071] Disintegrant 10%,

[0072] Adhesive 5%,

[0073] Lubricant 10%,

[0074] Fragrance 2%

[0075] The balance of water is solvent.

[0076] In this example, the surfactants are sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium laureth sulfate and cocamide DEA, each in a weight ratio of 10:5:3: 1;

[0077] In this embodiment, the disintegrant is dry starch.

[0078] In this embodiment, the binder is polyvinyl alcohol.

[0079] In this embodiment, the lubricant is glycerin, mineral oil, and silicon dioxide in a weight ratio of 3:1:1.

[0080] The invention provides a preparation method of laundry tablets, comprising the following steps:

[0081] (1) The surfactant and the saponin are added to hot water according to the weight percentage and mixed and stirred to form a mixture A;

[0082] (2) Weigh the original disintegra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com