Submersible AGV abut-joint method and system and submersible AGV

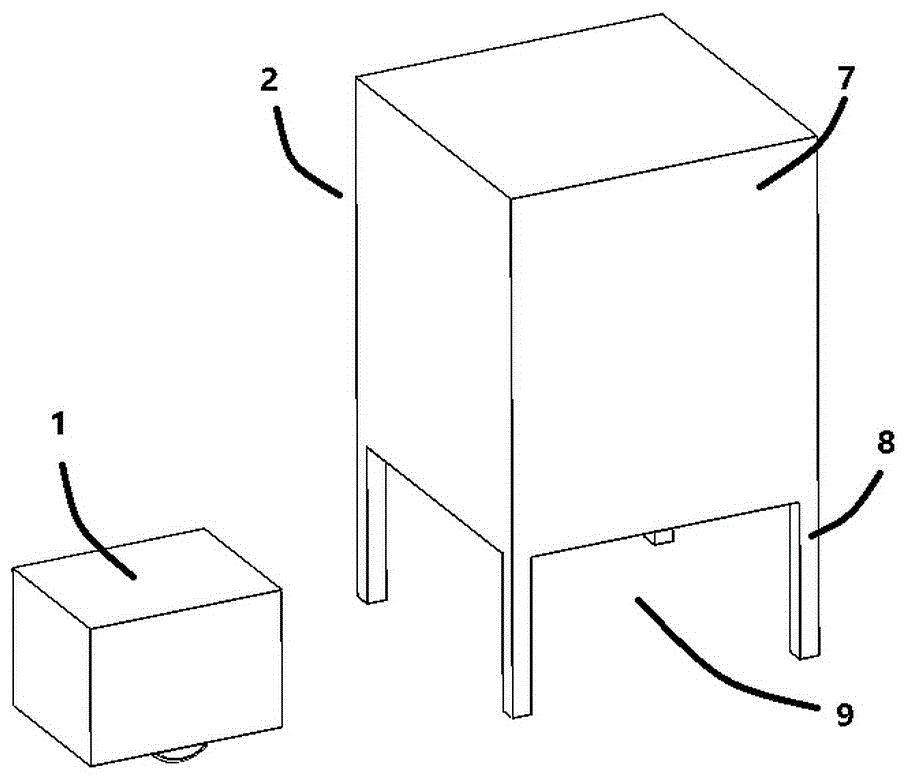

A docking mechanism and docking space technology, applied in the field of AGV, can solve the problems of single handling operation process, adjustment of operation process, large changes in workload, etc., to achieve the effect of reducing errors, accurate docking, and more in the field of warehousing or logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 12

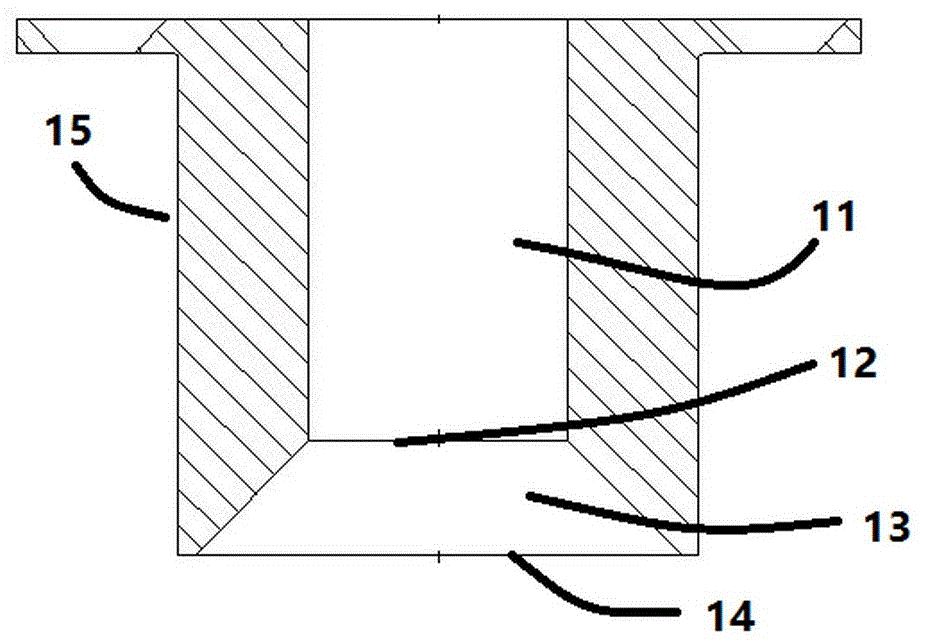

[0043] Embodiment 12: directly moving the AGV in the first translation direction reduces the first deviation distance to within the threshold range, and directly moving the AGV in the second translation direction reduces the second deviation distance to within the threshold range.

Embodiment approach 13

[0044] Embodiment 13: Rotate the AGV so that the advancing direction of the AGV is parallel to the first translation direction, and move the AGV in the first translation direction to reduce the first deviation distance to within the threshold range; rotate the AGV so that the advancing direction of the AGV is parallel to the first translation direction Two translation directions, moving the AGV in the second translation direction reduces the second deviation distance to within a threshold range. In order to enable the AGV to rotate in the docking space, the docking space reserves a space for the AGV to rotate.

[0045] In addition, the present invention provides a submerged AGV, including an acquisition unit, an operation unit, and a drive control unit,

[0046] The acquisition unit collects an image including at least one label on the first plane of the shelf; the calculation unit calculates the deviation of the current position of the AGV relative to the docking position acc...

Embodiment approach 22

[0058] Embodiment 22: the drive control unit controls the AGV to directly move the AGV in the first translation direction to reduce the first deviation distance to within a threshold range, and the drive control unit controls the AGV to directly move the AGV in the second translation direction to reduce the first deviation distance The second deviation distance is reduced to within the threshold range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com